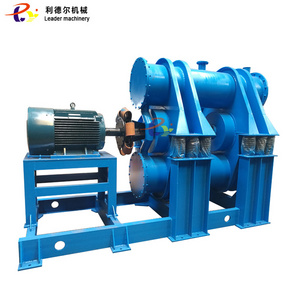

A rod mill is a mill in which the grinding body is a steel rod. The rod mill is generally a wet overflow type, which can be used as a first-stage open-circuit grinding. It is widely used in the first-grade grinding of artificial stone sand, concentrating plants and chemical power plants.

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Customized, Customizable

-

Weight:

-

30000 KG

-

Color:

-

Customizable

-

Quality:

-

Advanced Technology

-

Price:

-

Negotiable Resonable

-

Feeding Size:

-

Requiremend

-

Advantages:

-

High Efficiency Low Energy

-

Product name:

-

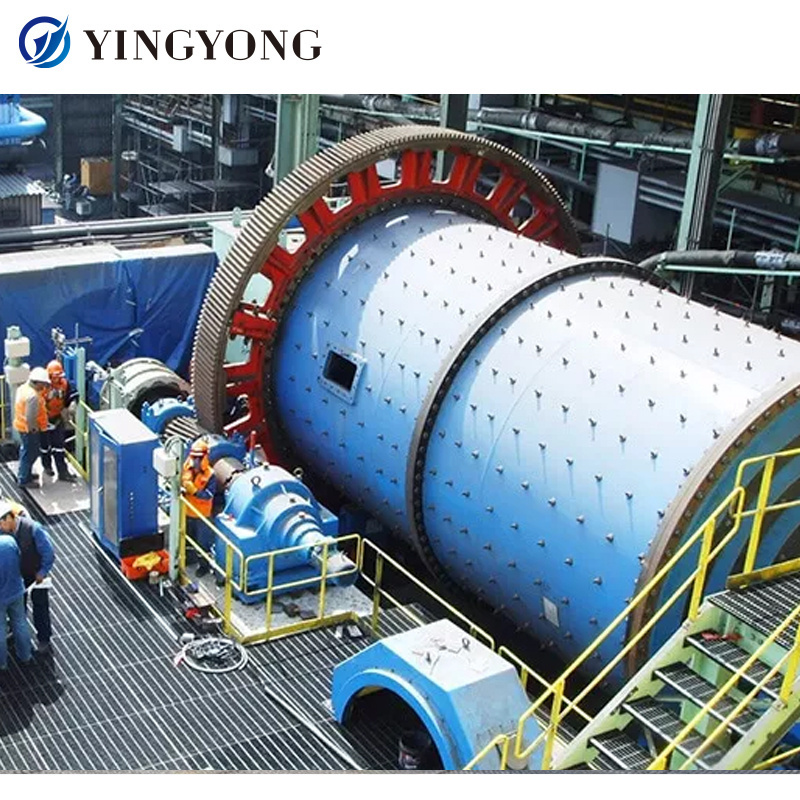

Ball Mill Machine

-

Application:

-

Stone Powder Grinding

Quick Details

-

Capacity(t/h):

-

Customized

-

Place of Origin:

-

Shanghai, China, shanghai, China

-

Brand Name:

-

YINGYONG

-

Dimension(L*W*H):

-

Customized, Customizable

-

Weight:

-

30000 KG

-

Color:

-

Customizable

-

Quality:

-

Advanced Technology

-

Price:

-

Negotiable Resonable

-

Feeding Size:

-

Requiremend

-

Advantages:

-

High Efficiency Low Energy

-

Product name:

-

Ball Mill Machine

-

Application:

-

Stone Powder Grinding

Product Description

Application

Energy saving mining ball mill is a key equipment in beneficiation plant.It is widely used in ore dressing production line such as Gold ore, Cooper ore, Magnetite ore, Antimony, Calcite, Kaolin, Mica, Clay, Bentonite etc Ferrou metal or Nonferrous metal materials.

ball mill

1) Ball Mill is an efficient tool for grinding many materials into fine powder;

2) Ball mill is used to grind many kinds of mine and other materials, or to select the mine;

3) Ball mill is widely used in building material, and chemical industry.

4) There are two ways of grinding: the dry way and the wet way.

5) Ball mill can be divided into tabular type and flowing type according to different expelling mine

6) To use the ball mill, the material to be ground is loaded into the neoprene barrel that contains grinding media.

7) As the barrel rotates, the material is crushed between the individual pieces of grinding media that mix and crush the product

into fine powder over a period of several hours.

8) The longer the ball mill runs, the finer the powder will be.

9) Ultimate particle size depends entirely on how hard the material you're grinding is, and the time how long the ball mill runs.

2) Ball mill is used to grind many kinds of mine and other materials, or to select the mine;

3) Ball mill is widely used in building material, and chemical industry.

4) There are two ways of grinding: the dry way and the wet way.

5) Ball mill can be divided into tabular type and flowing type according to different expelling mine

6) To use the ball mill, the material to be ground is loaded into the neoprene barrel that contains grinding media.

7) As the barrel rotates, the material is crushed between the individual pieces of grinding media that mix and crush the product

into fine powder over a period of several hours.

8) The longer the ball mill runs, the finer the powder will be.

9) Ultimate particle size depends entirely on how hard the material you're grinding is, and the time how long the ball mill runs.

Working Principle

Working principle

The rod mill is an asynchronous motor connected to the pinion through a reducer, which directly drives the peripheral large gear to decelerate and rotate, and drives the rotary part to rotate. The inside of the cylinder is equipped with a suitable grinding medium - steel rod, grinding medium in centrifugal force and friction Under the action of the material, the material to be ground continuously enters the inside of the cylinder from the feeding part, is crushed by the moving grinding medium, and discharges the product out of the machine by the force of overflow and continuous feeding to carry out the next process.

Technical parameters

|

Model

|

Cylinder Rotating Speed (r/min)

|

Feeding Size (mm)

|

Discharging Size (mm)

|

Capacity (t/h)

|

Power (kw)

|

|

900×1800

|

38

|

≤20

|

0.075-0.89

|

0.65-2

|

18.5

|

|

900×3000

|

38

|

≤20

|

0.075-0.89

|

1.1-3.5

|

22

|

|

1200×4500

|

35

|

≤25

|

0.074-0.4

|

1.6-5.8

|

55

|

|

1500×5700

|

29

|

≤25

|

0.074-0.4

|

3.5-6

|

110-130

|

|

2100×4500

|

23.7

|

≤25

|

0.074-0.4

|

8-43

|

245

|

|

2200×6500

|

21.7

|

≤25

|

0.074-0.4

|

14-26

|

380

|

|

2700×13000

|

20.7

|

≤25

|

0.074-0.4

|

50-90

|

630

|

|

Model

|

Speed(r/min)

|

Capacity(t/h)

|

Main Motor(KW)

|

Weight(t)

|

||||

|

MBS(Y)-1530

|

27

|

15~6

|

90

|

18

|

||||

|

MBS(Y)-1830

|

23.7

|

20~9

|

155

|

34.5

|

||||

|

MBS(Y)-2130

|

21.4

|

30~12

|

210

|

45

|

||||

|

MBS(Y)-2236

|

19

|

40~16

|

245

|

52

|

||||

|

MBS(Y)-2430

|

19

|

47~19

|

320

|

61

|

||||

|

MBS(Y)-2736

|

18.4

|

65~24

|

400

|

89

|

||||

|

MBS(Y)-3040

|

17

|

90~34

|

630

|

114

|

||||

|

MBS(Y)-3660

|

15.8

|

190~80

|

1400

|

198

|

||||

|

|

|

|

|

|||||

Product Display

Successful cases

|

Production site of gypsum powder in Pakistan

|

Company Profie

Our Business

Custom Visiting

FAQ

Hot Searches