- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

subject to client's

-

Power:

-

subject to machine model

-

Weight:

-

1000 KG

-

Dimension(L*W*H):

-

subject to machine model

-

Year:

-

2019

-

Application:

-

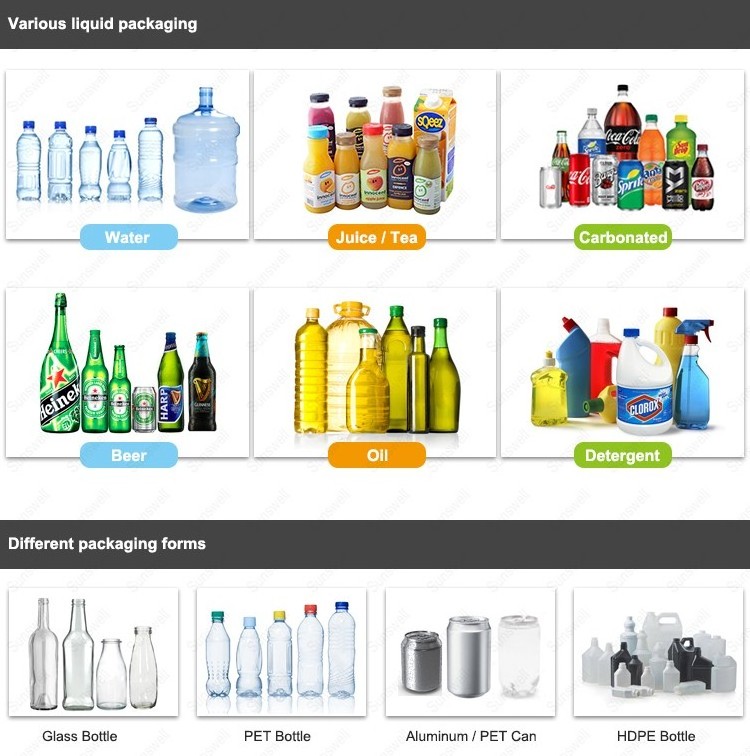

Beverage, juice, flavored milk,healthy energy drinks,ice teak

-

Packaging Type:

-

Bottles, Cans

-

Packaging Material:

-

Glass, Plastic

-

Automatic Grade:

-

Automatic

-

Driven Type:

-

Electric

-

Function:

-

Bottle Rinser-Bottle Filler-Bottle Capper

-

Cpacity:

-

2000botle/hour -36000bottle /hour

-

Bottle type:

-

PET plastic bottle ,glass bottle, PET canning

-

Bottle volume::

-

200ml- 2000ml

-

Certification:

-

CE/ISO9001

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SUNSWELL

-

Type:

-

Filling Machine

-

Voltage:

-

subject to client's

-

Power:

-

subject to machine model

-

Weight:

-

1000 KG

-

Dimension(L*W*H):

-

subject to machine model

-

Year:

-

2019

-

Application:

-

Beverage, juice, flavored milk,healthy energy drinks,ice teak

-

Packaging Type:

-

Bottles, Cans

-

Packaging Material:

-

Glass, Plastic

-

Automatic Grade:

-

Automatic

-

Driven Type:

-

Electric

-

Function:

-

Bottle Rinser-Bottle Filler-Bottle Capper

-

Cpacity:

-

2000botle/hour -36000bottle /hour

-

Bottle type:

-

PET plastic bottle ,glass bottle, PET canning

-

Bottle volume::

-

200ml- 2000ml

-

Certification:

-

CE/ISO9001

This milk filling machinery is suitable for milk juice product, it is consist of filler capper or Aluminum foil cap sealer, and sometimes people also use one stage washer or two stage washer.

Main configuration:

1) Material of filling valve: Stainless steel SUS304.

2) Material of rotary tray and machine platform of rinser and filler: Stainless steel SUS304.

3) Main motor: ABB/SEW/SIEMENS.

4) Sliding bearing: Igus.

5) Frequency inverter: Mitsubishi.

6) Touch screen: PROFACE.

7) PLC: Siemens/Mitsubishi.

8) Pneumatic components: FESTO/AIRTAC.

9) Seals: Busak+Shamban.

10) Photocell switch and proximity switch: TURCK

(1)Filling Technology

Milk Hot filling line

Milk flow meter filling line

Yogurt piston filling line

Suitable container

(2)Capping method

Screw capper

Ropp capper

Lug capper

Aluminum foil induction machine

Treatment System

Bolw Molding Machine

Filling Machine

Labelling Machine

Packaging System

Blowing-filling-capping CombiBlock

Flow Chart:

1.Preform input

2.Heating

3.Bottle blowing

4.Star wheel transmission

5.Filling

6. Capping

7.Product output

Any more questions, pls feel free to contact me !

Blowing-Filling-Capping Combiblock:

The innovative packing technology with a single unit machine to complete the whole process from preform to bottled liquid products.

Blower, filler and capper combined to one block, improves sanitary conditions, reduce cross contamination, increase running effieciency, and reduce energy consumption.

Any more questions, pls feel free to

contact me

!

1.About us

Set up in 2008, Sunswell leads the market in the field of liquid bottling, blow molding, labeling, packaging machinery and process technology for water, tea, juice, carbonated drinks, energy drinks, liquid, beer, edible oil, dairy and daily care products, etc.

We can customize liquid food production lines according to customers' demand. Every customer is the result of our proven experience and innovation. We continually focus on providing customers with advanced technology, engineering and facility that are designed with one motto in mind: ensure you to reach business goals with most optimized planning.

Why choose us?

(1)A to Z turnkey plant provider

(2)Fully automatic or economic solution optional

(3)10+ years of global market experience

(4)Serve customers over 50 countries and regions worldwide

Office & Factory & Workshop

2.Exhibitions

Sunswell,as an professional liquid filling and packing machine manufacturer,we often have chance to go out for exhibition to show our beverage filling machines and communicate processing technology with other industrial colleagues.

Any more questions, pls feel free to

contact me

!

3.Certifications

4.Service

Spare Parts / Maintenance, Installation & Commissioning / Training

No matter whether you're a newcomer or a sectoral expert – we have the specialists who can provide the comprehensively can-do support you need for planning a new facility in terms of not only actual beverage production, but also filling, packaging, utilities and logistics. In closely responsive consultation with you, from a multiplicity of possible options, we select the technologically and commercially most effective variant, handle the design and planning work, and bring the project to a successful conclusion at your chosen location. Sunswell is not only the consultant here, but also takes responsibility for executing the entire project.

Q1: which city are you in? how can I get to your factory? Are you a trading company or factory?

A1: We are in Zhangjiagang city, two hours driving from Shanghai. We are factory. Manufacturing mainly beverage filling and packagingmachines. We offer turnkey solutions with more than 10 years experience.

Q2: Why is your prices higher than others?

A2: We offer high-end machines in our business. Welcome to our factory to have a visit. And you will see the difference.

Q3: What is your delivery time?

A3: Normally 30-60 working days depends one machines, water machines are faster, carbonated drink machines are slower.

Q4: How to install my machines when it arrives? How much the cost?

A4: We will send our engineers to your factory to install the machines and train your staff how to operate the machines If needed. Or you can arrange engineers to study in our factory.

You are responsible for air tickets, accommodation and our engineer wage USD100/day/person.

Q5: How long time for installation?

A5: Subject to machines and the situation in your factory. If everything is ready, it will take about 10 days to 25 days.

Q6: How about the spare parts?

A6: We will send one year enough easy broken spare parts together with the machines for free, we suggest you buy more units to save international courier such as DHL, it is really costly.

Q7: What is your guarantee?

A7: We have one year guarantee and life-long technical support. Our service also including machine maintence.

Q8: What is your payment term?

A8: 30%T/T in advance as down payment, rest should be paid before shipping. L/C is supported also.