- Product Details

- {{item.text}}

Quick Details

-

Power:

-

20KW-50KW

-

Weight:

-

1650 KG

-

Application:

-

Glass Bottle, Tin, Can Food and Drinks

-

Sterilizing way:

-

Hot Water Spraying

-

Product name:

-

Cascade Steam Retort Canner Sterilization Autoclave Machine

-

Material:

-

Stainless Steel SUS304

-

Keywords:

-

Cascade Steam Retort

-

Heating way:

-

Steam Boiler

-

Usage:

-

Canned fruit and vegetable, seafood, coffee

-

Advantage:

-

Save energy and high efficiency sterilization

-

Processing Types:

-

Sterilizing Packing Canned

-

After-sales Service Provided:

-

Service Machinery Overseas

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DTS

-

Voltage:

-

220V/380V/415V/440V(or customized)

-

Power:

-

20KW-50KW

-

Weight:

-

1650 KG

-

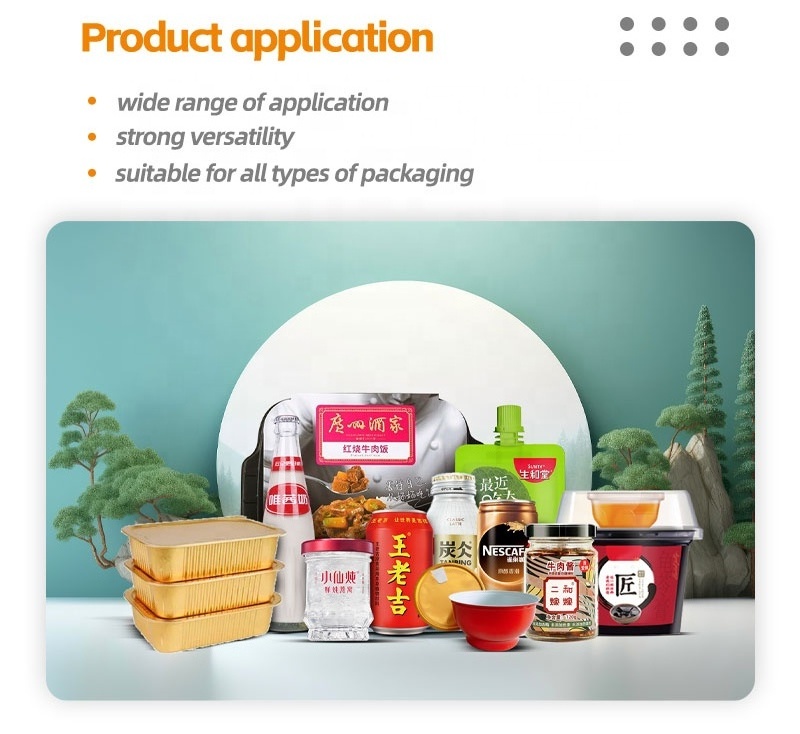

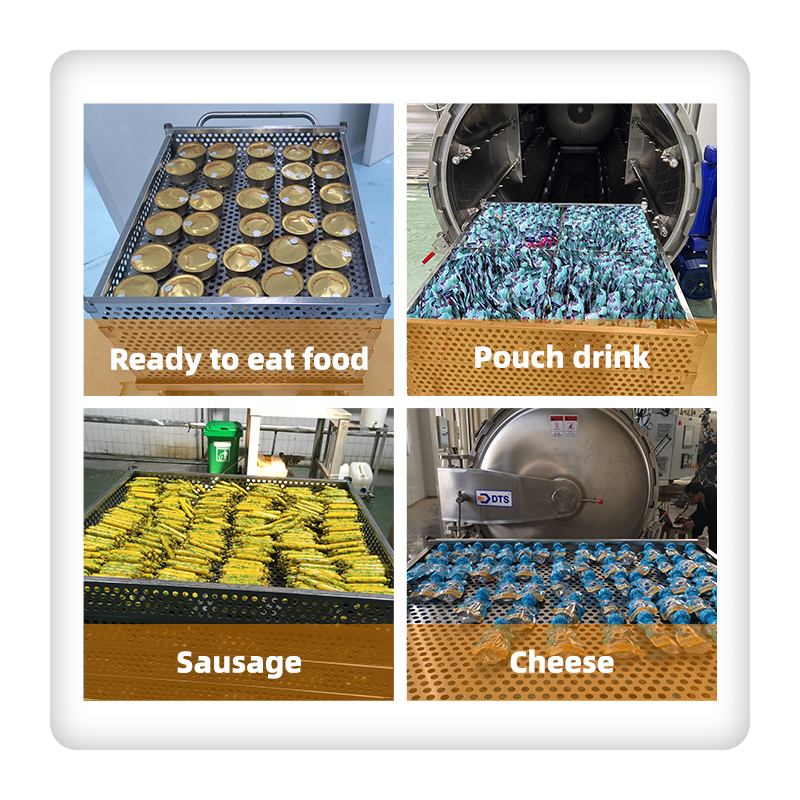

Application:

-

Glass Bottle, Tin, Can Food and Drinks

-

Sterilizing way:

-

Hot Water Spraying

-

Product name:

-

Cascade Steam Retort Canner Sterilization Autoclave Machine

-

Material:

-

Stainless Steel SUS304

-

Keywords:

-

Cascade Steam Retort

-

Heating way:

-

Steam Boiler

-

Usage:

-

Canned fruit and vegetable, seafood, coffee

-

Advantage:

-

Save energy and high efficiency sterilization

-

Processing Types:

-

Sterilizing Packing Canned

-

After-sales Service Provided:

-

Service Machinery Overseas

Economical Coconut milk Cascade Steam Retort Canner Sterilization Autoclave Machine

Drinks (vegetable protein, tea, coffee): Tin can; Aluminum can; Aluminum bottle; Plastic bottles, cups; Glass jars;

Dairy products: tin cans; plastic bottles, cups; glass bottles;

Vegetables and fruits (mushrooms, vegetables, beans): tin cans; glass bottles;

Meat, poultry: tin cans; aluminum cans;

Fish and seafood: tin cans; aluminum cans;

Baby food: tin cans; glass jars;

Pet food: tin can;

Product Introduction of Food Sterilizer Retort

1, Indirect heating and indirect cooling, sterilization process water and cooling water are not in direct contact to avoid secondary pollution of food, no water treatment chemical agents.

2, A small amount of sterilization process water quickly cycle heating, sterilization, cooling, no need to exhaust air before heating, the machine with advantages of low noise and save steam energy.

3, One-button operation, when the product enters the sterilizing retort and the door, only need to press the sterilizing button to complete the whole sterilization process.

4, The whole process adopts PLC automatic control, with multi-level password to eliminate the possibility of misoperation.

5, The retort with chain drive, it is convenient for basket accessing and saving manpower.

6, The condensed water on one side of the heat exchanger can be recycled to save water energy.

7, Equipped with triple safety interlock to prevent workers from mis-operation and avoid accidents.

Advantage of Food Sterilizer Retort

1, The temperature control system can choose linear and step according to different product and process heating modes, the temperature can be accurately controlled at +0.3°C, the heat distribution is uniform, the processing capacity is large, the sterilization effect is uniform.

2, The pressure control system constantly ADAPTS to the pressure changes inside the packaging during operation, and the pressure can be controlled at +0.05Bar, which is suitable for various packaging forms. With high efficiency, saving time and effort and stable operation.

3, Through the heat exchanger for indirect heating, cooling, steam and cooling water and process water do not contact to avoid product secondary pollution.

4, A small amount of process water quickly cycle, quickly reach the preset sterilization temperature, sterilization without exhaust air, save steam about 30%.

5, DTS is a member of IFTPS, the retorts in line with FDA/USDA certification.

6, Siemens PLC automatic control system is stable and reliable. When the operation is wrong, the system will automatically remind the operator to make a timely and effective response.

Q : What methods of payment are acceptable?

A: FOB, CFR & CIF optional; It’s mainly depend on client’s requirement;

Q: Do you have machines in stock?

A: Yes, but just the small-scale machines. Machines are different with other products, most of the large-scale machines are designed according to our customers' requirements.

Q: What’s the lead time after placing order ?

A :Usually it takes about 2-3 months after we received your deposit.

However, it would depend on our production line schedule(the timing clients place order)and the complication of the item.

Q: What is the cost of shipping?

A: Shipping cost is based on the following elements:

1.Type of container needed

2. Number of packages

3. Gross weight

4. Package volume

5. Destination port