- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

22*7*3.2 m

-

Year:

-

2020

-

Power (kW):

-

138 kW

-

Weight (KG):

-

4500 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Mixer:

-

110L Banbury

-

Feeder:

-

twin screw force feeder

-

Pelletizing system:

-

air cooling hot cutting system

-

Power(W):

-

260KW

-

Description:

-

Rubber accelerator masterbatch granulator

-

After Warranty Service:

-

Video technical support

-

Certification:

-

CE ISO9001

-

Name:

-

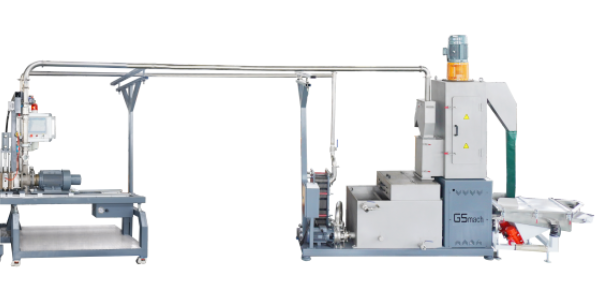

TPU filler masterbatch cable wire compounding line with Kneader

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

GS-mach

-

Voltage:

-

220/380/480 V

-

Dimension(L*W*H):

-

22*7*3.2 m

-

Year:

-

2020

-

Power (kW):

-

138 kW

-

Weight (KG):

-

4500 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Mixer:

-

110L Banbury

-

Feeder:

-

twin screw force feeder

-

Pelletizing system:

-

air cooling hot cutting system

-

Power(W):

-

260KW

-

Description:

-

Rubber accelerator masterbatch granulator

-

After Warranty Service:

-

Video technical support

-

Certification:

-

CE ISO9001

-

Name:

-

TPU filler masterbatch cable wire compounding line with Kneader

-

Marketing Type:

-

Ordinary Product

TPU masterbatch cable wire compounding line with Kneader

FEATURES AT A GLANCE

Product Overview

This type of configuration’s main features:

1 mixing can achieve the best dispersion and uniformity.

2 the mixing tank for the pourable, mixing shaft leakproof dry mechanical shaft seal, easy to change color for cleaning.

3 each mixing time takes about 6-10 minutes

4 Sealed mixing tank to ensure that mixed items, and to prevent environmental pollution.

5 the machine is durable, low failure rate, easy installation and operation, saving electricity.

6. this configuration’s easy maintenance,little screw mechanical wear and good dispersion.

1 mixing can achieve the best dispersion and uniformity.

2 the mixing tank for the pourable, mixing shaft leakproof dry mechanical shaft seal, easy to change color for cleaning.

3 each mixing time takes about 6-10 minutes

4 Sealed mixing tank to ensure that mixed items, and to prevent environmental pollution.

5 the machine is durable, low failure rate, easy installation and operation, saving electricity.

6. this configuration’s easy maintenance,little screw mechanical wear and good dispersion.

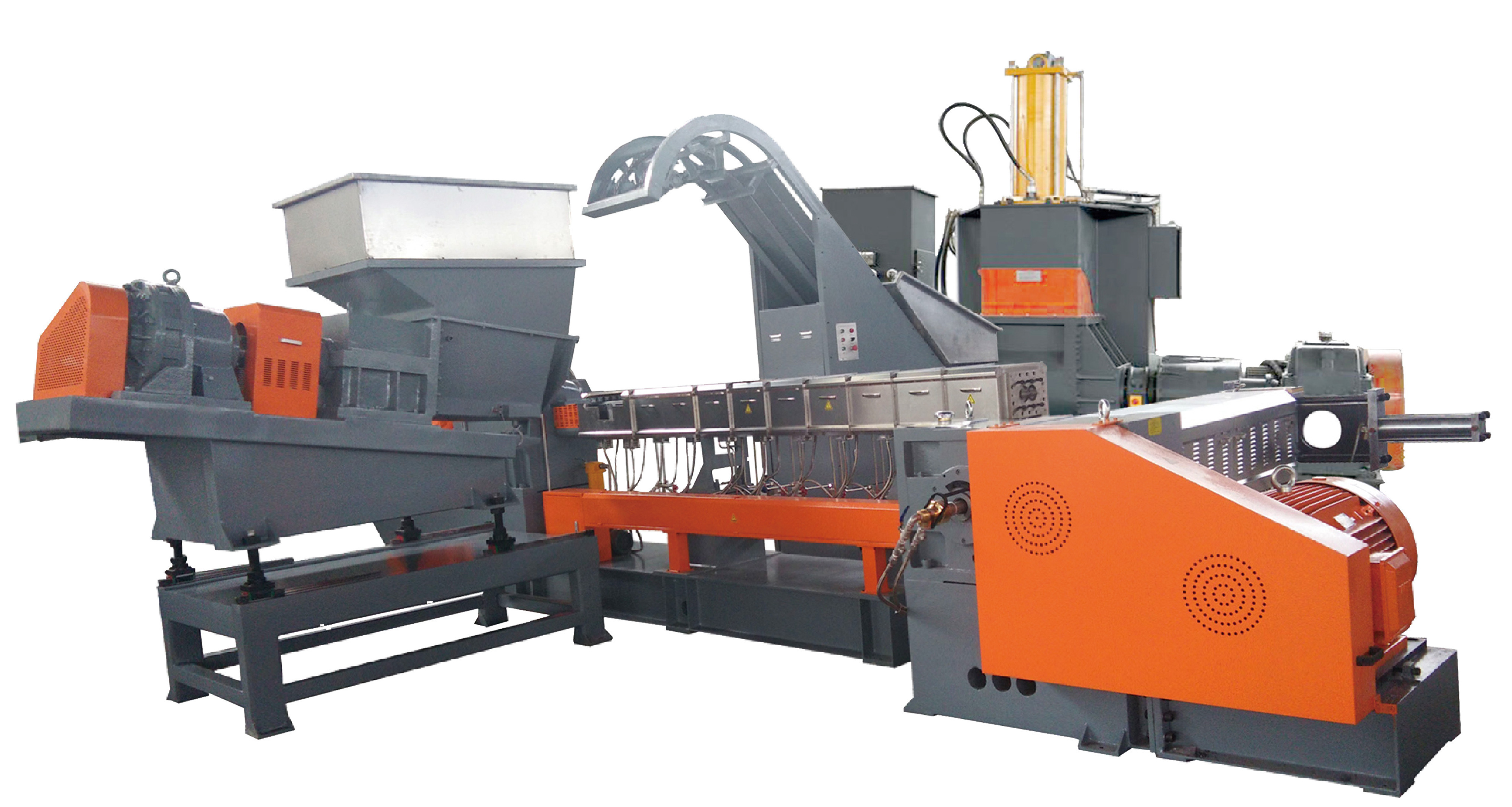

|

Model

|

Kneader

|

Kneader motor

Power

|

L/D

|

Screw Dia.

|

Single screw motor power

|

|

GSJ-50/100

|

55L

|

75KW

|

36-48:1

|

50.5/100MM

|

37-55KW

|

|

GSJ-65/150

|

75L

|

110KW

|

36-48:1

|

62.4/150mm

|

55-75KW

|

|

GSJ-75/180

|

110L

|

160KW

|

36-48:1

|

71/180mm

|

90-132KW

|

|

GSJ-95/200

|

150L

|

220KW

|

36-48:1

|

93/200mm

|

160-250KW

|

Application area

|

1

|

PE+Caco3 high filler masterbatch granulator

|

|

2

|

Stone paper plastic granulator

|

|

3

|

Low smoke free halogen cable material granulator

|

|

4

|

Shield cable material granulator

|

|

5

|

Carbon black masterbatch granulator

|

Related products

Hot Searches