- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

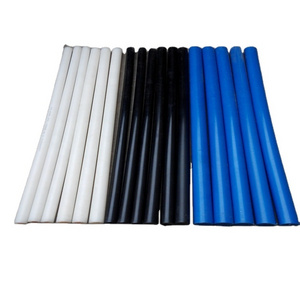

UHMW-PE solid plastic rod

-

Product name:

-

UHMW-PE solid plastic bar extruding uhmwpe rod plastic rod

-

Density:

-

0.98g/cm3

-

Color:

-

Natural,Black,White,Green,Blue,Yellow or Customized

-

Shape:

-

UHMW-PE solid plastic rod

-

Feature:

-

High Abrasion resistant

-

Application:

-

light industry., etc.

-

Certificate:

-

ISO9001

-

Package:

-

Wooden case

-

free sample:

-

available

-

Type:

-

UHMW-PE solid plastic rod

Quick Details

-

Processing Service:

-

Moulding, Cutting

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

GZ engineering plastic

-

Model Number:

-

UHMW-PE solid plastic rod

-

Product name:

-

UHMW-PE solid plastic bar extruding uhmwpe rod plastic rod

-

Density:

-

0.98g/cm3

-

Color:

-

Natural,Black,White,Green,Blue,Yellow or Customized

-

Shape:

-

UHMW-PE solid plastic rod

-

Feature:

-

High Abrasion resistant

-

Application:

-

light industry., etc.

-

Certificate:

-

ISO9001

-

Package:

-

Wooden case

-

free sample:

-

available

-

Type:

-

UHMW-PE solid plastic rod

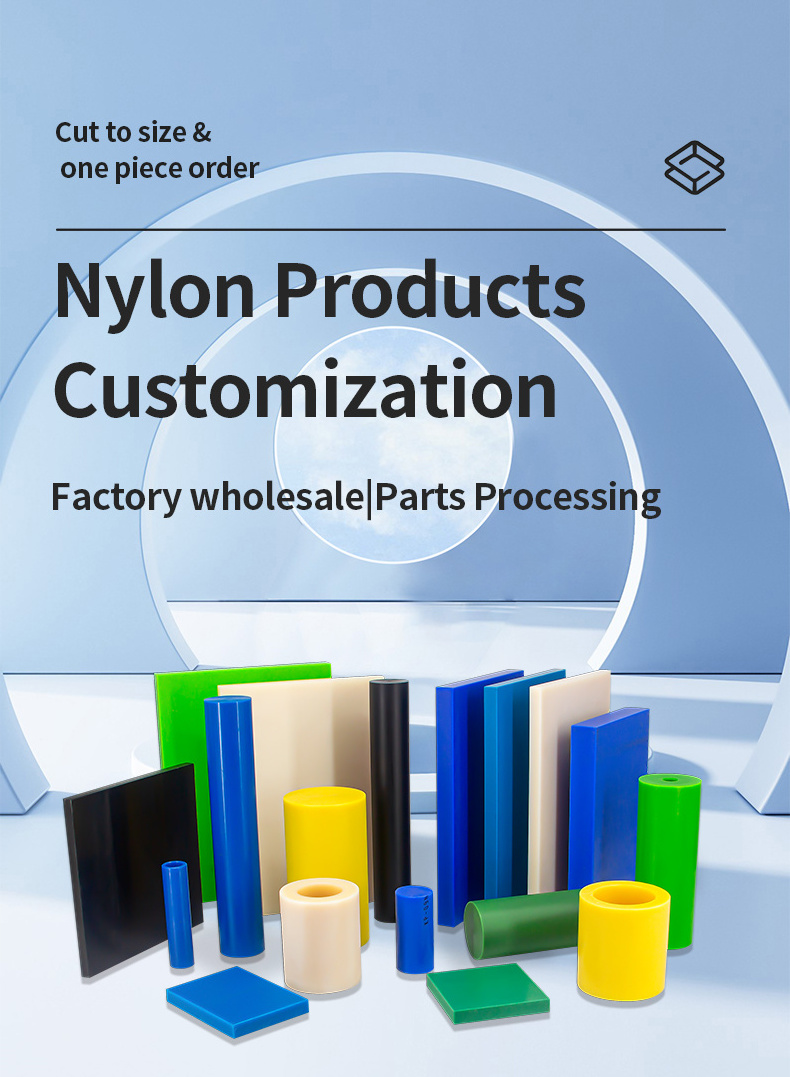

Engineering Plastic Extrusion Custom 1mm 2mm 3mm 4mm 5mm 6mm 8mm PA6 small diameter plastic Polyamide Pa6 Mc Nylon Rod Bars

Product Description

MC Nylon,means Monomer Casting Nylon, is a kind of engineering plastics used in comprehensive industries, has been applied almost every industrial field.The caprolactam monomer is first melted, and added catalyst, then poured it inside moulds at atmosphere pressure so as to shape in different castings, such as: rod, plate, tube. The molecule weight of MC Nylon can reach 70,000-100,000/mol, three times than PA6/PA66. Its mechanical properties are much higher than other nylon materials, such as: PA6/PA66. MC Nylon plays a more and more important role in the material list recommended by our country.

Color:

Natural、White、Black、Green、Blue、Yellow、Rice Yellow、Gray and so on.

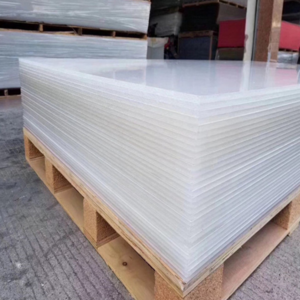

Sheet Size:

1000X2000X(Thickness:1-300mm)、1220X2440X(Thickness:1-300mm) 、1000X1000X(Thickness:1-300mm)、1220X1220X(Thickness:1-300mm)

Rod Size:

Φ10-Φ800X1000mm

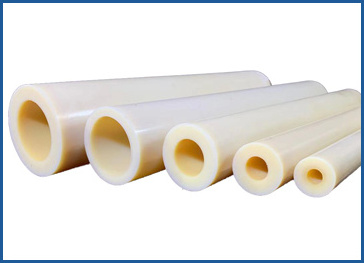

Tube Size:

(OD)50-1800 X (ID)30-1600 X Length(500-1000mm)

|

Property

|

Item No.

|

Unit

|

MC Nylon (Natural)

|

Oil Nylon+Carbon (Black)

|

Oil Nylon (Green)

|

MC901 (Blue)

|

MC Nylon+MSO2 (Light black)

|

|

1

|

Density

|

g/cm

3

|

1.15

|

1.15

|

1.135

|

1.15

|

1.16

|

|

2

|

Water absorption (23℃ in air)

|

%

|

1.8-2.0

|

1.8-2.0

|

2

|

2.3

|

2.4

|

|

3

|

Tensile strength

|

MPa

|

89

|

75.3

|

70

|

81

|

78

|

|

4

|

Tensile strain at break

|

%

|

29

|

22.7

|

25

|

35

|

25

|

|

5

|

Compressive stress(at 2%nominal strain)

|

MPa

|

51

|

51

|

43

|

47

|

49

|

|

6

|

Charpy impact strength (unnotched)

|

KJ/m

2

|

No break

|

No break

|

≥50

|

No break

|

No break

|

|

7

|

Charpy impact strength (notched)

|

KJ/m

2

|

≥5.7

|

≥6.4

|

4

|

3.5

|

3.5

|

|

8

|

Tensile modulus of elasticity

|

MPa

|

3190

|

3130

|

3000

|

3200

|

3300

|

|

9

|

Ball indentation hardness

|

N2

|

164

|

150

|

145

|

160

|

160

|

|

10

|

Rockwell hardness

|

--

|

M88

|

M87

|

M82

|

M85

|

M84

|

Guangzhou Engineering Plastics Group Company has studied and developed five kinds of different Oil Nylon Materials! Such as:

1: Oil Nylon (Oil casting Nylon)

1: Oil Nylon (Oil casting Nylon)

Oil Nylon, is the new engineering plastics that developed by Guangzhou Engineering Plastics

Industries Company. was the first authentic lubricating nylon that builds the liquid lubricant system during the processing stage,which makes its coefficient of friction is 50% lower than the general Nylon, the wear-resistance is 10 times than the generalones.

2: MC901 (Blue)

This improved MC Nylon, has striking blue color, which is better than general PA6/PA66 in the performance of toughness,flexibility, fatigue-resistance and so on. It is the perfect material of gear, gear bar, transmission gear and so on.

3: MC Nylon + Oil (Green)

Oil MC Nylon is specially developed for the parts of non-self-lubrication, heavy-loading and

low-speed-running, which obviously resulted in a substantial increase in bearing life -- 5 times that of general plastics and 25

times that of phosphor bronze!

4 : MC Nylon + MSO2 (Light black)

MC Nylon added MSO2 can remain the impact-resistance and fatigue-resistance of casting nylon, as well as it can improve the

loading capacity and wear-resistance. It has a wide application in making gear, bearing, planet gear, seal circle and so on.

5 : Oil Nylon + Carbon (Black)

Oil Nylon added carbon, has the very compact and crystal structure, which is better than the general casting nylon in the performance of high mechanical strength,wear-resistance, anti-aging, UV resistance and so on. It is suitable for making the bearing and other wear mechanical parts.

Industries Company. was the first authentic lubricating nylon that builds the liquid lubricant system during the processing stage,which makes its coefficient of friction is 50% lower than the general Nylon, the wear-resistance is 10 times than the generalones.

2: MC901 (Blue)

This improved MC Nylon, has striking blue color, which is better than general PA6/PA66 in the performance of toughness,flexibility, fatigue-resistance and so on. It is the perfect material of gear, gear bar, transmission gear and so on.

3: MC Nylon + Oil (Green)

Oil MC Nylon is specially developed for the parts of non-self-lubrication, heavy-loading and

low-speed-running, which obviously resulted in a substantial increase in bearing life -- 5 times that of general plastics and 25

times that of phosphor bronze!

4 : MC Nylon + MSO2 (Light black)

MC Nylon added MSO2 can remain the impact-resistance and fatigue-resistance of casting nylon, as well as it can improve the

loading capacity and wear-resistance. It has a wide application in making gear, bearing, planet gear, seal circle and so on.

5 : Oil Nylon + Carbon (Black)

Oil Nylon added carbon, has the very compact and crystal structure, which is better than the general casting nylon in the performance of high mechanical strength,wear-resistance, anti-aging, UV resistance and so on. It is suitable for making the bearing and other wear mechanical parts.

Finished Product Display

We support provide customized various PCTFE special-shaped parts pieces of PCTFE injection products, tolerance is not more than 0.01 mm.

components, please feel free to contact us.

How to get a quotation:

1. Prepare a picture or 3D drawings

2. You want the product material

3. Quantity per order, estimated annual requirements send to our email:

2. You want the product material

3. Quantity per order, estimated annual requirements send to our email:

sales@gz-plastics.com

, ask us

TM

online, We can offer you quickly and give you the professional advise to save mold cost and keep high quality.

Application

1. Spheric bowl, impeller, blade,valve plate, cam.

2. Pipe, stuffing box, rack, belt pulley, pump rotor.

3. Shaft sleeve, bearing bush, lining, gear, lining plate.

4. Worm gear, roller copper guide rail, piston ring,seal ring, slide block.

5. Nylon PA6 Products substitute for wear parts of mechanical equipment, or used as quick- wear parts of equipment instead of copper and alloy.

Our Factory

Specializing in the production of "engineering plastic accessories"

of high-tech enterprises, the company has a set of imported production equipment and CNC processing equipment, processing means advanced, strong technical force.

The company has rich experience, strong strength and participated

in

many high-end exhibitions;Many partners from other countries are visiting.

Certificate

Companies strictly enforce the ISO9001(2008)international quality certification system, the product quality conforms to the eu RoHS standard.

The company has professional product technical consultation and after-sales service;Good market reputation (quality assurance, reasonable price, timely delivery!)We will wholeheartedly provide you with the best quality products, the most thoughtful service!

Professional Team

Guangdong Engineering Plastics Industries Co., Ltd!,We have the professional engineer teams and sales teams, and we have technology and experiences in engineering plastic industry for morethan 26 years! Our company is located in Huangpu District,

Guangzhou City, China, where the logistics is developed! With the rich experiences and technology for manufacture, design,research and development ability, support personalized customization. We have full set of high efficiency producing equipment and advanced numerical control machines, such as: molding injection machines, CNC molding manufacture machines, fine carving machines, Horizontal lathes, milling machines. We can customize all kinds of Engineering plastics products according to our customers’drawings or samples.

Guangzhou City, China, where the logistics is developed! With the rich experiences and technology for manufacture, design,research and development ability, support personalized customization. We have full set of high efficiency producing equipment and advanced numerical control machines, such as: molding injection machines, CNC molding manufacture machines, fine carving machines, Horizontal lathes, milling machines. We can customize all kinds of Engineering plastics products according to our customers’drawings or samples.

Cooperation

Cooperate with many well-known companies

FAQ

Q1. We don't have drawings, can we produce according to the samples we provide?

A1. OK

Q2. How to customize plastic parts?

A2. Customized according to drawings

Q3. Can I make a sample for testing first?

A3. OK

Q4. How long is the proofing cycle?

A4. 2-5 days

Q5. What are your processing equipment?

A5. CNC machining center, CNC lathe, milling machine, engraving machine, injection molding machine, extruder, molding machine

Q6. What craftsmanship do you have for processing accessories?

A6. According to different products, different processes are used, such as machining, extrusion, injection molding, etc.

Q7. Can injection products be surface treated? What are the surface treatments?

A7. OK. Surface treatment: spray paint, silk screen, electroplating, etc.

Q8. Can you help assembling the product after it is made?

A8. OK.

Q9. How much temperature can the plastic material withstand?

A9. Different plastic materials have different temperature resistance, the lowest temperature is -40℃, and the highest temperature is 300℃. We can recommend materials according to the working conditions of your company.

Q10. What certifications or qualifications does your company have?

A10. Our company’s certificates are: ISO, Rohs, product patent certificates, etc.

Q11. How scale is your company?

A11. Our company covers an area of 2,000 square meters and has 100 employees.

Hot Searches