- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

≥ 99.7%

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

XINYU

-

Dimension(L*W*H):

-

340 *340* 790 mm

-

Weight:

-

17 KG

-

Product name:

-

small filling machine

-

Function:

-

Liquid Filling Sealing

-

Bottle type:

-

PET Plastic Bottle

-

Suitable for:

-

Liquid Food

-

Processing Types:

-

Semi-Automatic Bottle Filling Machine

-

Feature:

-

Low Cost

-

Material:

-

SUS304

-

Advantage:

-

Easy Operation High Efficiency

-

After-sales Service Provided:

-

Online Support

-

Name:

-

Bottle Liquid Filling Machine

Quick Details

-

Machinery Capacity:

-

Other

-

Packaging Material:

-

Plastic, Metal, Glass, Other

-

Filling Material:

-

Beer, Other, Milk, Water, Oil, Juice

-

Filling Accuracy:

-

≥ 99.7%

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

XINYU

-

Dimension(L*W*H):

-

340 *340* 790 mm

-

Weight:

-

17 KG

-

Product name:

-

small filling machine

-

Function:

-

Liquid Filling Sealing

-

Bottle type:

-

PET Plastic Bottle

-

Suitable for:

-

Liquid Food

-

Processing Types:

-

Semi-Automatic Bottle Filling Machine

-

Feature:

-

Low Cost

-

Material:

-

SUS304

-

Advantage:

-

Easy Operation High Efficiency

-

After-sales Service Provided:

-

Online Support

-

Name:

-

Bottle Liquid Filling Machine

Product Paramenters

Product Paramenters

|

Filling Range

|

5-50ml

|

|

Capacity of Hopper

|

22lbs/10kg

|

|

Height range

|

7.87"/200mm

|

|

Bottle diameter range

|

3-15 mm

|

|

Filling material

|

liquid with good liquidity

|

|

Filling accuracy

|

±1%

|

|

Machine size

|

10.6 x 10.6 x 27.5 inch/ 270 x 270 x 710 mm

|

|

Packing size

|

13.4 x 13.4 x 31.1 inch/ 340 × 340 × 790 mm

|

|

Net weight

|

28.5lbs/13 kg

|

|

Gross weight

|

37.5lbs/17 kg

|

Product Description

Application

Our Innovative Newest manual filling machine adopts a piston type structure, the liquid for 0-50g quantitative filling. This product can only be used for liquid with good liquidity. Applicable to the , cosmetic, pesticides and special industries, and also can be used for sealing the hose has the quantitative filling.

How To Use

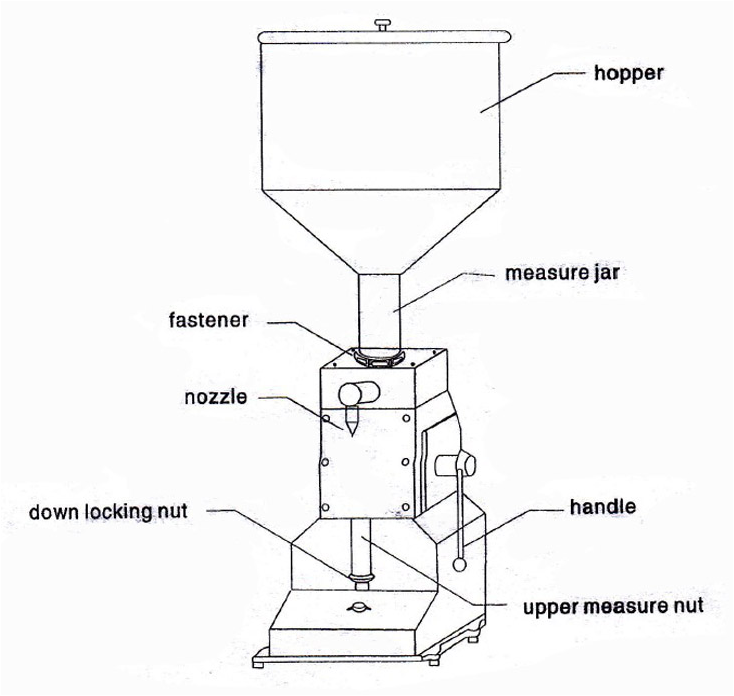

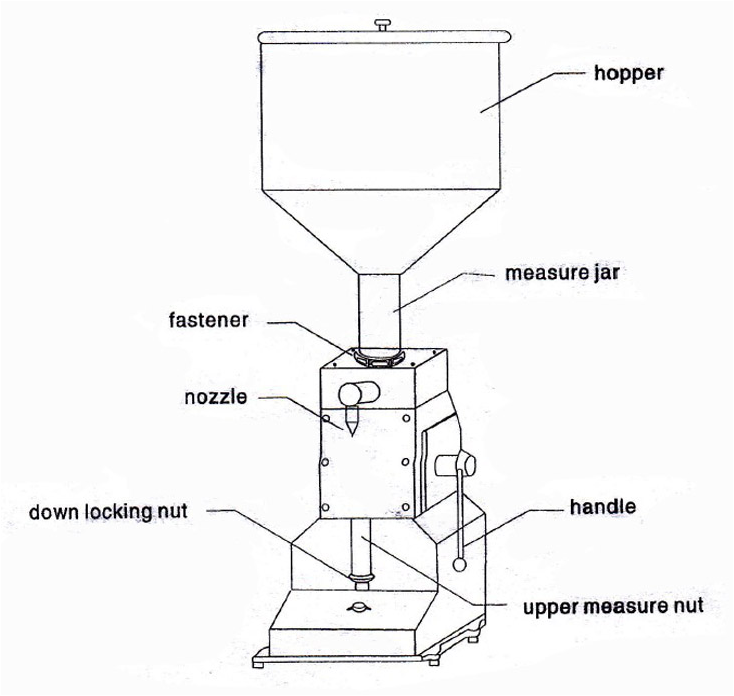

Make the handle up at first, then let the locking nut(Flg2.25) slip, circumgyrate the measure net(Flg2.26) CCW to the filling dose, or CW to reduce. Circumgyrate the locking nut close while you get right dosage.

Make the handle up at first, then let the locking nut(Flg2.25) slip, circumgyrate the measure net(Flg2.26) CCW to the filling dose, or CW to reduce. Circumgyrate the locking nut close while you get right dosage.

Details Images

This manual filling machine has been especially designed by our factory for medium or small size enterprises including laboratories, hospitals, and beauty parlors. Its design is compact, efficient, and easy to use. All parts of the machine that touch the material being filled are Made of stainless steel and Polytetrafluoroethylene. On average the machine can fill 40 bottles per minute (depending the operation speed, product density, draw length, and fill speed). Stainless steel construction, a rugged rotary

valve system, and a completely pneumatic operation design serve to extend service life. The silica gel O-ring system can withstand 392° Fahrenheit heat. Piston feed speed is adjustable and a no-drip option is included. The machine is extremely accurate (+/- 1%) and simple to operate. It is also very easy to clean and maintain thanks to sanitary stainless steel quick disconnect fittings.

The machine has simple and reasonable structure, convenient manual operation, without any energy. With the filling volume regulator knob, quantitative discharging, filling rate and filling speed can be controlled manually. The material contact part uses stainless steel, suitable for use under acidic medium, to meet production and health requirements. The machine hopper capacity of 10 kg, the user can be set on the filling capacity.

valve system, and a completely pneumatic operation design serve to extend service life. The silica gel O-ring system can withstand 392° Fahrenheit heat. Piston feed speed is adjustable and a no-drip option is included. The machine is extremely accurate (+/- 1%) and simple to operate. It is also very easy to clean and maintain thanks to sanitary stainless steel quick disconnect fittings.

The machine has simple and reasonable structure, convenient manual operation, without any energy. With the filling volume regulator knob, quantitative discharging, filling rate and filling speed can be controlled manually. The material contact part uses stainless steel, suitable for use under acidic medium, to meet production and health requirements. The machine hopper capacity of 10 kg, the user can be set on the filling capacity.

Packaging & Shipping

1. The machine is PE film winding to protect machine off corrosiv e and rust;

2 . Export standard plywood case, composite material, fumigation-free;

Hot Searches