- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Comark

-

Weight:

-

390 KG

-

Dimension(L*W*H):

-

2000*1600*1300 MM

-

Product name:

-

Bottle Unscrambler Machine Equipment Linear Unscrambler For Bottle

-

Function:

-

Arranging bottles

-

Advantage:

-

10 Years Experiences

-

Packing material:

-

Plastic bottles

-

Key words:

-

Linear Bottle Unscrambler

-

Gas Consumption:

-

2.5 m3/h

-

Production Speed:

-

Customization

-

Material:

-

304 Stainless Steel

Quick Details

-

Voltage:

-

220V

-

Power:

-

1.5KW

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Comark

-

Weight:

-

390 KG

-

Dimension(L*W*H):

-

2000*1600*1300 MM

-

Product name:

-

Bottle Unscrambler Machine Equipment Linear Unscrambler For Bottle

-

Function:

-

Arranging bottles

-

Advantage:

-

10 Years Experiences

-

Packing material:

-

Plastic bottles

-

Key words:

-

Linear Bottle Unscrambler

-

Gas Consumption:

-

2.5 m3/h

-

Production Speed:

-

Customization

-

Material:

-

304 Stainless Steel

Production Description

Automatic Bottle Unscrambler Machine Equipment Linear Unscrambler For Bottle

The equipment adopts the integrated design of the hoist and the main machine, which saves space. It is mainly used for wide-mouth bottles and bottles with large differences in capacity. The width of some mechanisms can be adjusted to adapt to a wide range of bottle types.

This machine is used for sorting disordered polyester bottles. Scattered and disordered bottles are sent to the bottle storage circle of the bottle unscrambler through the elevator. Depending on the centrifugal force of the turntable, the ends of the bottles are connected to the centrifugal disk, and the multi-stage belt mechanism is exported to stabilize the bottle. body, hold the bottle and enter the claw mechanism, the bottle mouth is hooked forward and turned over, the bottom of the bottle cannot be hooked forward, and finally the bottle mouth runs forward and backward, and then through the last level of belt, the bottle is erected, and the bottle sorting process is completed , and enter the next process through the output of the air-conveyed bottle conveying system. The body of the machine is made of high-quality stainless steel, and other parts are also made of non-toxic and durable series of materials. Some imported parts are used for the electrical and pneumatic systems. The whole working process is controlled by PLC programming, so the equipment failure rate is low and the reliability is high.

Product Paramenters

|

NO

|

Item

|

Data

|

|

1

|

Host size

|

2000*1600*1300mm

|

|

2

|

Production speed

|

customization

|

|

3

|

Air pressure

|

need

|

|

4

|

Gas consumption

|

2.5 m3/h

|

|

5

|

Suitable bottle type

|

The details are subject to the bottle provided by the customer

|

|

6

|

Monitor rate

|

1.5KW 220V voltage 50hz

|

|

7

|

Equipment weight

|

390KG

|

Work Process

♦

Manually pour the bottle into the elevator bucket.

♦

The bottle is sent to the sorting bin of the bottle unscrambler by the elevator.

♦

Bottles enter the bottle unscrambler compartment for sorting, high-speed centrifugal output, multi-stage belt output, hook claws turn over the bottle, and the belt clamps the bottle upright.

Product Details

Large capacity turntable

Strong compatibility, suitable for round、

square,、flat square,、special-shaped plastic

bottles of various sizes and specifications.

smart touch screen

The scientific bottle unscrambling control system avoids the bottle damage caused by the mutual collision of the bottles in the bottle unscrambling barrel.

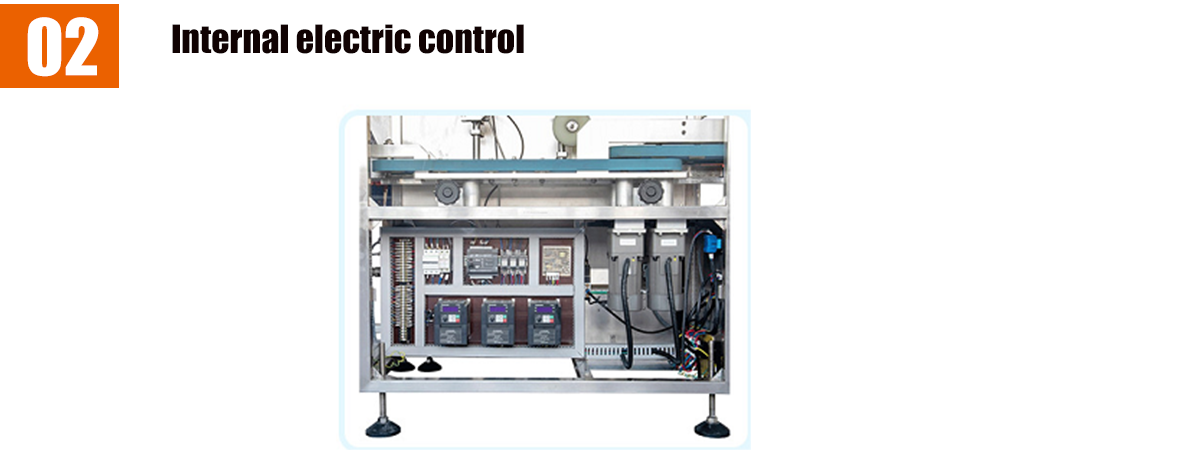

Using brand precision electronic components, safe and stable, reasonable layout, easy maintenance.

The export of the equipment adopts multi-stage belt output, first stabilizing the bottle body, then conveying through clamping, docking hook claw bottle turning mechanism, high-speed turning, adjustable belt width, wide adaptability.

Control System

|

S/ N

|

Name

|

Specification

|

|

1

|

Main motor

|

2000*1600*1300mm

|

|

2

|

Main turntable motor

|

Domestic brand 120W

|

|

3

|

Elevator motor

|

Domestic brand 150W

|

|

4

|

Brush motor

|

Domestic brand 60W

|

|

5

|

Bottle motor

|

Domestic brand 40W

|

|

6

|

Hook bottle motor

|

Domestic brand 90W

|

|

7

|

Vertical bottle motor

|

Domestic brand 90W

|

|

8

|

Bearing

|

Pairs of tapered rollers in Harbin

|

|

9

|

PLC

|

Inovance

|

|

10

|

Low voltage electrical appliances

|

Schneider

|

|

11

|

Main Turntable Inverter

|

Matsushita

|

|

12

|

Hoist inverter

|

Matsushita

|

|

13

|

Bottle splitting motor speed controller

|

Domestic brand

|

|

14

|

Vertical bottle motor inverter

|

Panasonic

|

|

15

|

Touch screen

|

MCGS

|

Related Products

Successful Production Video

Why Choose Us

Zhangjiagang Comark Machinery Co.,ltd

Zhangjiagang Comark Machinery Co., Ltd. is located in Zhangjiagang Economic Development Zone on the Bank of the Yangtze River. It has an international

standard plant of 20000 square meters

. It is an enterprise specializing in the R & D and production of beverage packaging machinery.Our team has more than 20 professional technical R & D personnel,

2 doctors

of food science and technology,

5

masters and

15

senior professional engineers. This provides a favorable guarantee for the stable operation of the machine with high output. Our company's equipment is of high quality and can operate stably.We have more than

15

years of packaging experience. We understand market supply and demand and can provide market analysis, project budget, equipment and technology configuration,

machines installation

and operator training, etc. We always provide

turnkey solutions

and related services.

FAQ

Q:How to find COMARK Machinery?

A:

Search Alibaba, Made in China, Google, Youtube and find suppliers and manufacturer and not traders

Visit exhibition in different countries

Send Comark Machine an request and tell your basic inquiry

Comark Machine sales manager will reply you in short time and add instant chatting tool

Q:If we purchase machines, what can you provide for us?

A1: We can provide whole solutions.We have professional engineer who analysis production demand based on customer market demand and customer budget .

Visit exhibition in different countries

Send Comark Machine an request and tell your basic inquiry

Comark Machine sales manager will reply you in short time and add instant chatting tool

Q:If we purchase machines, what can you provide for us?

A1: We can provide whole solutions.We have professional engineer who analysis production demand based on customer market demand and customer budget .

A2:

We have the bottle shape design according to customer inquire. We also can provide the machines layout for you according your factory figure plan.

A3:

We will send our professional engineer to your factory as soon as you get all your machines ready, for installation, testing and teaching your technicians how to run the machines.

Q:Do you have any reference project?

A: We have reference project in most countries, and you can visit their factories if we get the permission of the customer. And we have made video of every machine and uploaded them to Youtube.I can share with you.

Q:When can I get my machine after I paid?

A: We will deliver the machines on time as the date we agreed both side. Normally production time is around 35-75 days. The exact time depends on what kinds of machine you ordered. The shipping time is based on your destination port.

Q: Do you have a CE certificate?

A: For every model of machine, it has a CE /ISO/BV certificate and so on.

Q:Do you have any reference project?

A: We have reference project in most countries, and you can visit their factories if we get the permission of the customer. And we have made video of every machine and uploaded them to Youtube.I can share with you.

Q:When can I get my machine after I paid?

A: We will deliver the machines on time as the date we agreed both side. Normally production time is around 35-75 days. The exact time depends on what kinds of machine you ordered. The shipping time is based on your destination port.

Q: Do you have a CE certificate?

A: For every model of machine, it has a CE /ISO/BV certificate and so on.

Hot Searches