- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

EPDM(made in Europe) disc air diffuser with micro bubbles

-

Diameter:

-

215mm, 260mm

-

Aeration capacity:

-

2.5m3/h

-

Service area:

-

0.6m2/piece

-

Connector size:

-

G3/4' screwed connection

-

The total weight:

-

350g, 550g

-

air bubble size:

-

1~3mm

-

Oxygen utilization ratio:

-

22%~40%

Quick Details

-

Core Components:

-

epdm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

YULONG

-

Product name:

-

EPDM(made in Europe) disc air diffuser with micro bubbles

-

Diameter:

-

215mm, 260mm

-

Aeration capacity:

-

2.5m3/h

-

Service area:

-

0.6m2/piece

-

Connector size:

-

G3/4' screwed connection

-

The total weight:

-

350g, 550g

-

air bubble size:

-

1~3mm

-

Oxygen utilization ratio:

-

22%~40%

Since 1995, YULONG ® -AERATION has sold more than 2.5 million fine bubble wastewater diffusers worldwide. Our core competence and sole focus is engineering, designing, and client support for bubble diffuser assemblies and membranes.

| MODEL | HDH-215 | HDH-260 |

| Diameter of Rubber membrane(mm) | 215 | 260 |

| Air Flow(m 3 /h) | 0.5~5 | 1~8 |

| Service Area(m 2 /piece) | 0.2~0.6 | 0.3~0.8 |

| Oxygen Utilization Ratio(%) | 22~40 | 30~50 |

| Oxygenation Capacity(kg O 2 /kw·h ) | 0.13~0.40 | 0.20~0.50 |

| Theoretical Power Efficiency(kg O2/kw·h ) | 4.5~6.5 | 6.0~8.0 |

| Resistance Loss(Pa) | < 3000 | <300 0 |

| Air Bubble Diameter(mm) | 1~3 | 1~3 |

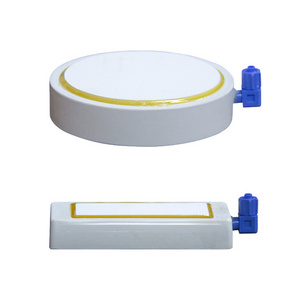

| Connector size | G3/4" Screwed connection | |

| Note: The above data is tested in 4M depth clear water. | ||

| WORKING CONDITION | ||

| Ambient Air Temperature(℃) | (-30.0~45.0℃) (max:90~100℃) | |

| Contact fluid temperature(℃) | 4~50℃ | |

| pH | 4~9 | |

| Max.Working Depth(m) | 10 | |

| Durability | 24h/day Non-stop Running ok | |

| MAIN SPACE PARTS MATERIAL | ||

| Rubber Membrane | EPDM | |

| Connectors | EPDM | |

| Clamping Ring | Strengthened PP | |

| Support Plate | Strengthened PP | |

| Refulx Valve | Strengthened PP+EPEM | |

| Air Pipe | ABS/UPVC | |

| Air Distributing Main Pipe | ABS/UPVC | |

| Pipe Fitting | ABS/UPVC | |

| Fastener of Main Pipe | 304 Stainless Steel | |

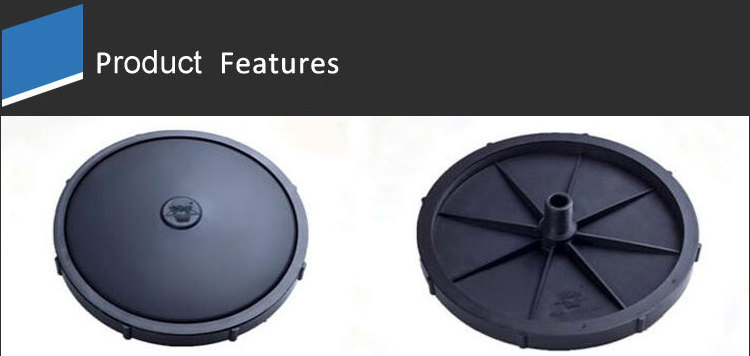

1. In practical projects, when fine bubble diffuser working, we find that the region of the highest stress is mainly in the outer edges and central membrane. As a result, the stretching of membrane with traditional design is limited, the membrane is in a high stress state for some time, it is very fragile and easy tear, furthermore faces high aeration resistance. Under such condition, the oxygenation capacity decreases, the power consumption and maintenance cost increase.

In order to avoid the abovementioned defects, we thicken the outer edges and central membrane. Unique designs can greatly improve the service life of YULONG ® fine bubble diffuser.

2. Double check valve and p eriphery fold sealing 3. Imported EPDM material from France

structure can prevent diaphram dropping off from

the PP plate.

4. The diffuser has been used for 11 years, we took it from our clients's factory.

5. Unique porous technology makes the disc air diffuser bubble release evenly, with High Oxygen Transmission efficiency (OTE)

6. Good effect on saving in power, and low operating cost

7. The membrane has good self-cleaning and anti-clogging property

8. Easy to exclude failure, easy maintance and management

9. Simple structure for easy installation

10. In the long run, project cost is lower.

1.Aeration for SBR, MBBR reaction basin,contact oxidation pond ,and activated sludge aeration basin in sewage disposal plant;

2.Aeration for denitrification/dephosphorization aerobic processes;

3.Aeration for excreta and animal waste water treatment plant;

4.Aeration of deep aeration basin;

5.Aeration for high concentration wastewater aeration basin, and areation for regulating pond of waste water treatment plant;

6.Aeration of fishpond and other applications.