The biggest difference with the black annealed is that the heating is not in contact with

air, with nitrogen and other inert gas has been protected, the surface color remains the same as the cold-rolled strip, in

addition to black annealed use is also used for surface tin plating and other surface treatment, beautiful and elegant.

Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Hardness:

-

Mid Hard

-

Skin Pass:

-

Yes

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Shougang

-

Application:

-

building and so on

-

Width:

-

customization

-

Length:

-

coil or sheet

-

Grade:

-

SPCC

-

Product Name:

-

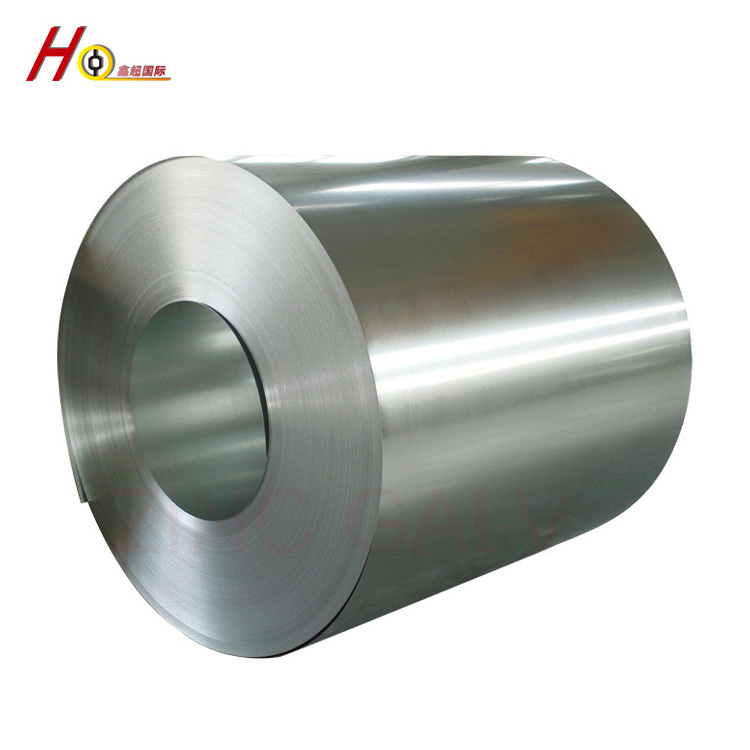

Prime cold rolled steel coils continuous black annealed

-

width:

-

30-1500mm

-

Material:

-

SPCC/SPCD/SPCE/DC01/DC03/DC04/St12/St13/St14/CS A/DS

-

Coil Weight:

-

3~7 Tons

-

Technology:

-

Cold Rlloed

-

Surface:

-

oiled

-

Shape:

-

Coil Roll

-

Usage:

-

building

-

Package:

-

Standard Sea Worthy Package

Quick Details

-

Type:

-

Steel Sheet

-

Thickness:

-

customization, 0.3-3.0mm

-

Surface Treatment:

-

Normal Oiled

-

Hardness:

-

Mid Hard

-

Skin Pass:

-

Yes

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Shougang

-

Application:

-

building and so on

-

Width:

-

customization

-

Length:

-

coil or sheet

-

Grade:

-

SPCC

-

Product Name:

-

Prime cold rolled steel coils continuous black annealed

-

width:

-

30-1500mm

-

Material:

-

SPCC/SPCD/SPCE/DC01/DC03/DC04/St12/St13/St14/CS A/DS

-

Coil Weight:

-

3~7 Tons

-

Technology:

-

Cold Rlloed

-

Surface:

-

oiled

-

Shape:

-

Coil Roll

-

Usage:

-

building

-

Package:

-

Standard Sea Worthy Package

Product Description

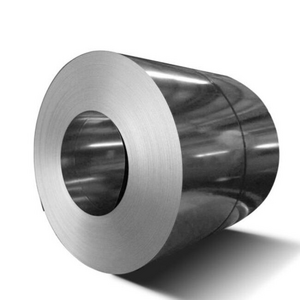

CRC /COLD ROLLED COIl

Often used in the steel industry, as opposed to hot rolled coil. It refers to the steel strip which is rolled into a certain thickness directly by a roller and rolled into a whole roll by a winder at room temperature. Compared with hot rolled coil, cold rolled coil surface bright, high finish, but will produce more internal stress, often annealing treatment after cold rolling.

Because there is no heating in the production process, there are no defects such as pitting and oxide sheet which often appear in hot rolling, and the surface quality is good and the finish is high. Moreover, the dimensional precision of cold-rolled products is high, and the properties and organization of the products can meet some special requirements, such as electromagnetic properties, deep drawing properties and so on.

Because there is no heating in the production process, there are no defects such as pitting and oxide sheet which often appear in hot rolling, and the surface quality is good and the finish is high. Moreover, the dimensional precision of cold-rolled products is high, and the properties and organization of the products can meet some special requirements, such as electromagnetic properties, deep drawing properties and so on.

Multiple processing equipment, good raw materials and mature cutting technology, the product cutting surface is smooth and

burr-free, the whole beautiful and solid.

NO DEFORMATION

Reliable materials, stable performance support large bearing capacity, not easy to deform and long service life.

Provide a variety of models and specifications, can be customized. Large inventory, good price and timely delivery.

Cold rolled steel advantage

Cold-rolled steel is further rolled thin to a target thickness at room temperature.

2. It is possible to obtain extremely thin strips that cannot be produced by hot rolling (up to 0.001 mm or less).

3.The surface quality of cold-rolled products is superior, there are no defects such as pitting, hot-pressed iron oxide, etc.,which are often found in hot-rolled coils, and coils of different surface roughness (glossy or hemp) can be produced according to user requirements. Rough surface, etc., to facilitate the processing of the next process.

4.The cold rolled plate has a good mechanical properties and process properties (such as higher strength, lower yield limit, good deep drawability, etc.).

5.High-speed rolling and full-continuous rolling can be realized with high productivity.

Compared with hot rolled steel:

Cold rolled steel is more accurate in thickness and has a smooth, beautiful surface, as well as various superior mechanical

properties, especially in terms of processing properties.

properties, especially in terms of processing properties.

Because cold rolled coils are brittle and hard,

they are not suitable for processing, so they are usually required to undergo annealing, pickling and surface flattening before

they are put into circulation in the market.

they are not suitable for processing, so they are usually required to undergo annealing, pickling and surface flattening before

they are put into circulation in the market.

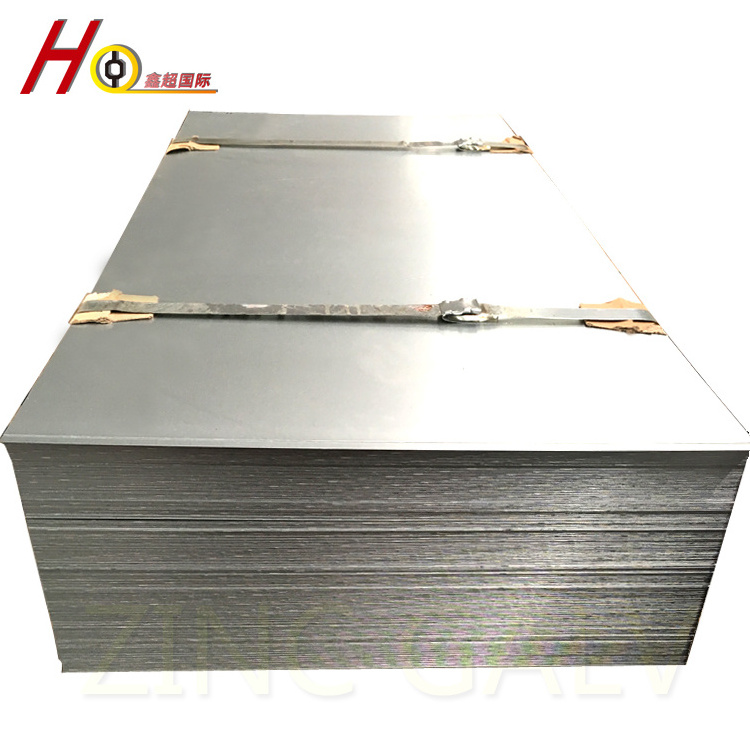

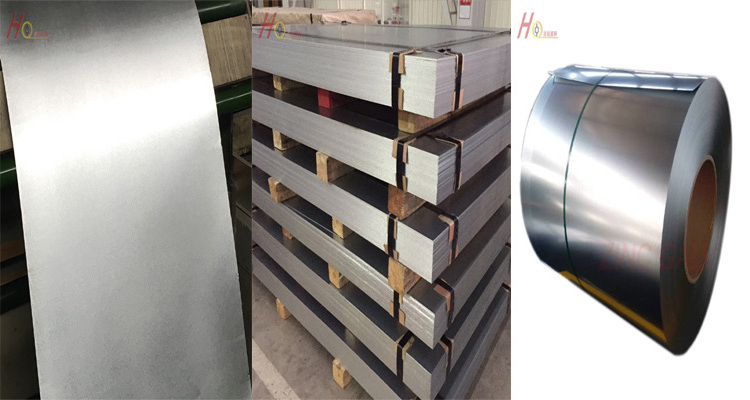

Detailed Images

Bright Annealed

Black Annealed

Cold rolled strip heated directly to annealing

temperature, the surface color becomes black due to high temperature exposure to air. The physical properties become softer and

are generally used for deep processing of steel strips for re-stretching, stamping and larger deformation.

temperature, the surface color becomes black due to high temperature exposure to air. The physical properties become softer and

are generally used for deep processing of steel strips for re-stretching, stamping and larger deformation.

Cold rolled production line

Cold rolling steel production line adopts the most advanced cold rolling equipments and

automatic thickness control system in China. Bright cold rolled steel and black cold rolled steel are available to producing with its urface oil-coated.

automatic thickness control system in China. Bright cold rolled steel and black cold rolled steel are available to producing with its urface oil-coated.

Slitting and cutting

The cold-rolled coil products are accurate in

size, uniform in thickness, and the thickness difference of the coils generally does not exceed 0.1- 1.2 mm or less, which can

meet the requirements of high-precision tolerances.

The surface quality of cold-rolled products is superior, there are no defects such as pitting, hot-pressed iron oxide.which are often found in hot-rolled coils, and coils of different surface roughness (glossy or hemp) can be produced according to user requirements. Rough surface, etc., to facilitate the processing of the next process.

size, uniform in thickness, and the thickness difference of the coils generally does not exceed 0.1- 1.2 mm or less, which can

meet the requirements of high-precision tolerances.

The surface quality of cold-rolled products is superior, there are no defects such as pitting, hot-pressed iron oxide.which are often found in hot-rolled coils, and coils of different surface roughness (glossy or hemp) can be produced according to user requirements. Rough surface, etc., to facilitate the processing of the next process.

Product Presentation

|

Product Name

|

Prime cold rolled steel coils continuous black annealed CRC coil STEEL SHEET

|

|

Thickness

|

0.12-3.0mm

|

|

Width

|

coil/sheet/customization

|

|

Grade

|

JIS G3141-SPCC-SD, SPCC-SB, SPCD-SD, SPEC-SD

JIS G3135-SPFC 340/390/440 EN10130-DC01, DC03, DC04 SAE1006, SAE1008 ASTM A424-TypeⅡ |

|

Surface

|

Bright/Black annealed

Oil/Slight Oil/Oiless |

|

Standard

|

ISO,JIS,ASTM,AS EN

|

|

Mill Origin

|

China

|

Packing&Shipping

Certificate

Related Products

Company Introduction

Tianjin Zinc Galv International Trade Co., Ltd. is located in Tianjin, China, which established in 2006 as subsidiary company of Tangshan Haoyun Group. The major business of Zinc Galv is exporting advantaged steel products from Haoyun Group.

We are big scale stockist and grade A distributor of more than 15 big steel mills in northern China. Our major products including

HR, CR, GI, PPGI, GL and ZAM steel coils and sheets.

We own a factory named Tangshan XinHaoXuan metal products Co., Ltd., major function is steel coils storage and metal processing.

This plant covers 20000㎡,equipped with 8 production lines for cutting and slitting. There are more than 20000 tons of ready stock coils in our plant all year round.

We have attended many overseas exhibitions during past years, such as BIG 5 Dubai; PHILI CONSTRUCT, EXCON PERU, SAUDI BUILD, ARCHITECT TAILAND and so on. After years development, we have established deep business relationship with customers come from South America, Middle East, Southeast Asia, Africa, east European and so on.

During past 2023, the annual turnover of Haoyun Group exceeds USD500 million, the amount of weight breaks 700 thousand tons.

Welcome to contact us, and we are looking forwarder to cooperating with you in near future.

We export products to Korea, Sri Lanka, Philippines, Bangladesh, Thailand, Pakistan, Singapore, Vietnam, Austria,USA. Mexico, Fiji, Ireland, Italy, France, South Africa, Iraq, Bukina Faso etc. totally over 40 countries. Our well-equipped facilities and excellent quality control throughout all stages enable us to guarantee total customer satisfaction.

Our Advantages

Why choose us

1. Best Competitive Prices

2. High Quality

3. Excellent Service

4. Free Samples

5. Good Sea Freight (We have our owned logistics company.)

2. High Quality

3. Excellent Service

4. Free Samples

5. Good Sea Freight (We have our owned logistics company.)

Contact Info

Juanita Bai

Email: juanita(at)zincgalv.com

MOB(whatsapp): +86-13920306113

Wechat: ts00860315

Hot Searches