- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

221227

-

Product name:

-

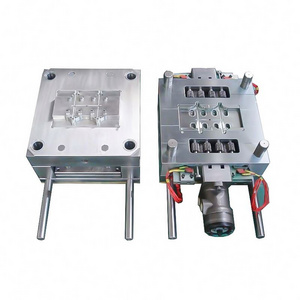

injection molding plastic parts manufacturer

-

Certification:

-

ISO9001:2015

-

Surface treatment:

-

Polishing/smooth,texture/frosted, painting, plating, printing

-

Tolerance:

-

0.02mm -0.05mm

-

Mould material:

-

45#/50#/P20/718/2738/NAK80/S136

-

Mould Life:

-

300000-500000shots

-

Mould Base:

-

LKM.HASCO

-

Advantage:

-

20 Years Experience

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Alpine

-

Model Number:

-

221227

-

Product name:

-

injection molding plastic parts manufacturer

-

Certification:

-

ISO9001:2015

-

Surface treatment:

-

Polishing/smooth,texture/frosted, painting, plating, printing

-

Tolerance:

-

0.02mm -0.05mm

-

Mould material:

-

45#/50#/P20/718/2738/NAK80/S136

-

Mould Life:

-

300000-500000shots

-

Mould Base:

-

LKM.HASCO

-

Advantage:

-

20 Years Experience

|

high quality OEM plastic injection molding products making for Alpine Mold

|

|

|

|

|

||||

|

plastic material

|

ABS/PP/PC/PE/PVC/TPE/TPU...

|

|

|

|

||||

|

Material in mould

|

45#/50#/P20/718/2738/NAK80/S136

|

|

|

|

||||

|

Mould Standard

|

LKM; HASCO; DME

|

|

|

|

||||

|

Runner System

|

hot/cold runner

|

|

|

|

||||

|

Cavity

|

Single or Multi Cavities

|

|

|

|

||||

|

Mould life

|

300,000-500,000shots

|

|

|

|

||||

|

Surface treatment

|

Polishing/smooth,texture/frosted, painting, plating, printing

|

|

|

|

||||

|

Plastic Quality Certifaction

|

RoSH,food grade, Medical grade, UL, UV

|

|

|

|

||||

|

Experience

|

20 years experience in plastic injection mold making and plastic products

|

|

|

|

||||

|

Certification

|

ISO9001:2015, Alibaba SGS

|

|

|

|

||||

Zhonghesheng mold specializes in high quality Plastic Injection Molding with more than 100 employees. It is founded in 2002. At the beginning, we produced the plastic injection molds and the household plastic parts for domestic companies, or some international trade companies. Now we are concentrated in international market. After more than 16 years'development in this industry, we know the international plastic injection molding standards well, such as: HASCO, DME, MISUMI, LKM. Until now, we have produced more than 5000 sets of molds and have been molding millions of medical plastic parts for Sony, Toshiba, Volvo, Gree, Midea! Our products reach to the range of electronic products, automotive products, home appliances,medical parts and so on.

Packing Details :Wooden box for plastic mold , and carbon box for plastic products.

Delivery Details : 15-25 days for mould making , and parts delivery time is depends on quantity of production.

Q1: Are you trading company or manufacturer ?

A: We are manufacturers.

Q2. When can I get the quotation?

A: We usually quote within 2 days after we get your inquiry.

If you are very urgent, please call us or tell us in your email so that we can quote for you first.

Q3. How long is the lead-time for mold?

A: It all depends on the products' size and complexity. Normally, the lead time is 15-25 days.

Q4. I have no 3D drawing, how should I start the new project?

A: You can supply us a molding sample, we will help you finish the 3D drawing design.

Q5. Before shipment, how to make sure the products quality?

A: If you don't come to our factory and also don't have the third party for inspection, we will be as your inspection worker.

We will supply you a video for production process detail include process report, products size structure and surface detail, packing detail and so on.

Q6. What is your payment terms?

A: Mold Payment: 40% deposit by T/T in advance, 30% second mold payment before sending out the first trial samples, 30% mold balance after you agree the final samples.

B:Production Payment: 50% deposit in advance, 50% before sending out the final goods.

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit for best quality products .

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

A: We are manufacturers.

Q2. When can I get the quotation?

A: We usually quote within 2 days after we get your inquiry.

If you are very urgent, please call us or tell us in your email so that we can quote for you first.

Q3. How long is the lead-time for mold?

A: It all depends on the products' size and complexity. Normally, the lead time is 15-25 days.

Q4. I have no 3D drawing, how should I start the new project?

A: You can supply us a molding sample, we will help you finish the 3D drawing design.

Q5. Before shipment, how to make sure the products quality?

A: If you don't come to our factory and also don't have the third party for inspection, we will be as your inspection worker.

We will supply you a video for production process detail include process report, products size structure and surface detail, packing detail and so on.

Q6. What is your payment terms?

A: Mold Payment: 40% deposit by T/T in advance, 30% second mold payment before sending out the first trial samples, 30% mold balance after you agree the final samples.

B:Production Payment: 50% deposit in advance, 50% before sending out the final goods.

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit for best quality products .

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Hot Searches