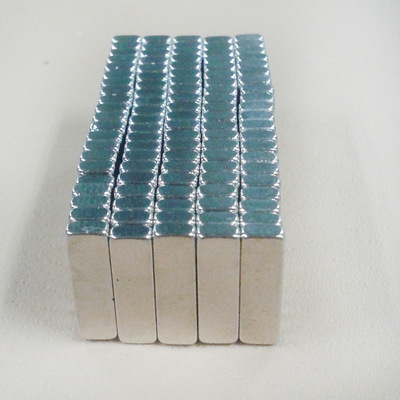

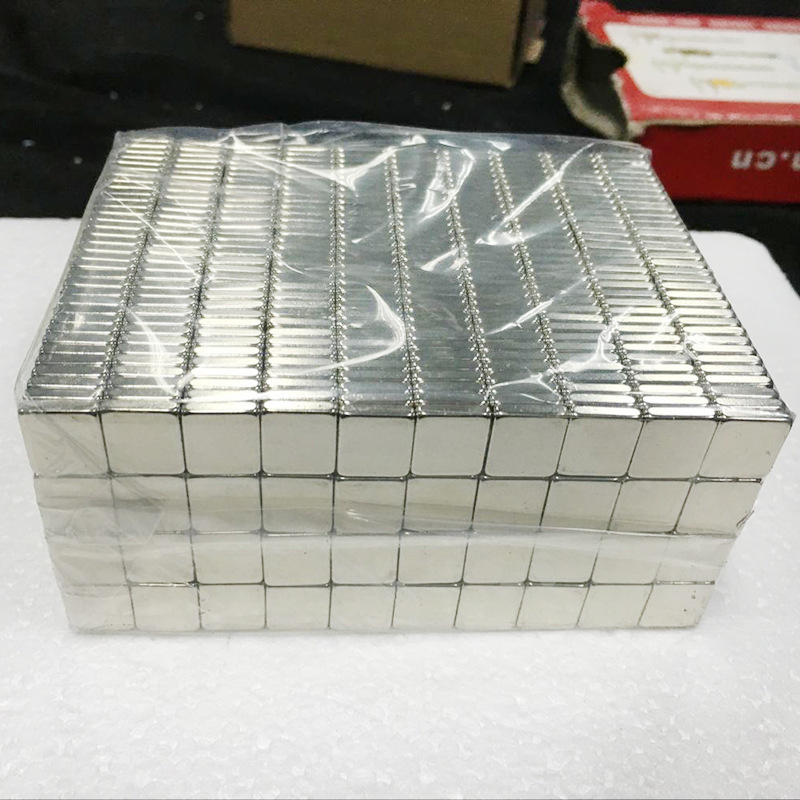

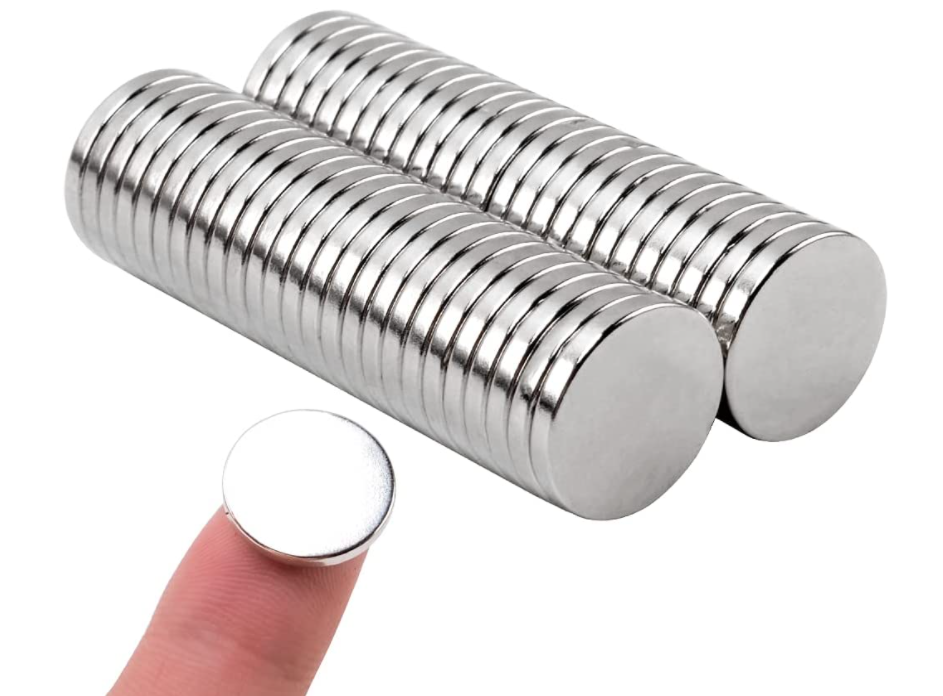

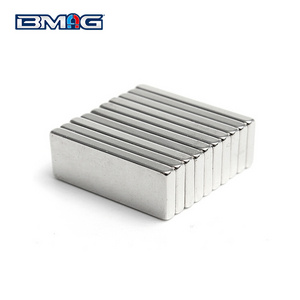

Strictly choose the good quality Raw Material, refuse to use the bad or

scrap raw material

sufficient work and sufficient materials, no cutting corners