- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/Customized

-

Power:

-

model

-

Weight:

-

1800

-

Dimension(L*W*H):

-

model

-

Product name:

-

3 Phases Separation Machine

-

Application:

-

Liquid Liquid Solid Separation

-

Discharge:

-

Full-automatically

-

Electrical Control Cabinet:

-

With PLC and Frequency conversion

-

Capacity:

-

5-120 L/H

-

Drum Speed:

-

0-6000/min(with Step-less Adjustment)

-

Drum diameter:

-

250-750mm

-

Material:

-

Stainless Steel 304/316L

-

Product Keywords:

-

Tricanter Centrifuge Oil Separator

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Marketing Type:

-

Hot Product 2022

-

Brand Name:

-

Shenzhou

-

Voltage:

-

220V/Customized

-

Power:

-

model

-

Weight:

-

1800

-

Dimension(L*W*H):

-

model

-

Product name:

-

3 Phases Separation Machine

-

Application:

-

Liquid Liquid Solid Separation

-

Discharge:

-

Full-automatically

-

Electrical Control Cabinet:

-

With PLC and Frequency conversion

-

Capacity:

-

5-120 L/H

-

Drum Speed:

-

0-6000/min(with Step-less Adjustment)

-

Drum diameter:

-

250-750mm

-

Material:

-

Stainless Steel 304/316L

-

Product Keywords:

-

Tricanter Centrifuge Oil Separator

Product Overview

The Decanter Centrifuge for Soybean Oil Separator is an advanced industrial machine that separates soybean oil from other solids and liquids. It is a critical piece of machinery in the soybean oil industry, offering powerful and efficient separation capabilities that are unmatched by other types of separators.

This centrifuge uses a finely-tuned system of mechanical and centrifugal forces to separate the soybean oil from the other substances in the mixture. It features a rotating drum that rapidly spins around its central axis, causing the oil and solids to separate according to density and viscosity. The solids are expelled from the centrifuge through one end, while the soybean oil is collected through the other end.

One of the key features of this Decanter Centrifuge is its incredible speed and efficiency. Thanks to its powerful motor and advanced design, it can process large volumes of soybean oil mixture in a short amount of time, making it ideal for use in large-scale industrial operations. Additionally, this separator is known for its durability and reliability, ensuring that it can meet the demands of even the most demanding industrial settings.

The Decanter Centrifuge for Soybean Oil Separator is also easy to use and maintain, thanks to its intuitive design and advanced control systems. It features a range of automated features that make it easy to operate, requiring minimal training and oversight from operators. Moreover, it is designed to be easy to clean and maintain, with features such as

self-cleaning mechanisms that help reduce downtime and maintenance costs.

self-cleaning mechanisms that help reduce downtime and maintenance costs.

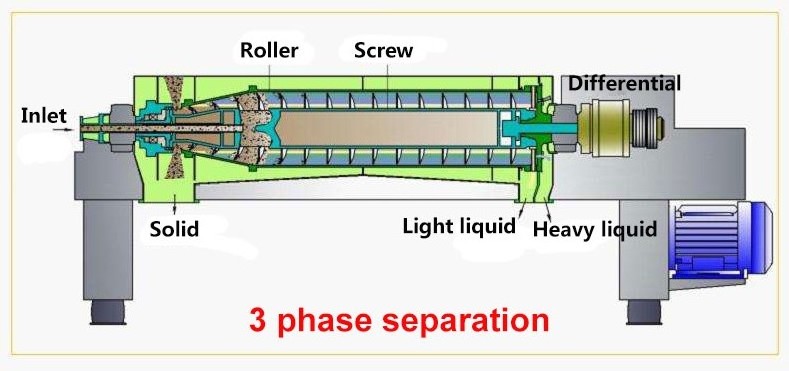

Working principle

Drum and screw are working with higher speed at a certain differential rotation. Material is transported into spiral tube continuously , accelerated after the rotary drum, in under the action of centrifugal force field, the heavier solid deposit formed in the drum wall sediment layer.The feeding screw continuously pushes the solid phase of the deposit to the drum cone, and then out of the drain.The lighter liquid phase forms the inner liquid ring, which is continuously overflowed by the large end of the drum, and is discharged through the drain outlet.The machine operates at full speed, continuously feeding, separating, washing and discharging.It has the characteristics of compact structure, continuous operation, stable operation, strong adaptability, large production capacity and convenient maintenance.It is suitable for the suspension with solid phase particle size greater than 0.005mm and concentration range of 2-40%.Widely used in chemical industry, light industry, food, environmental protection and other industries.

Technical parameter

Advantage

Feature of 3 phase decanter cen

trifuge

1. Compact structure

2. Easy sealing

3. Stable operation, low noise, large processing capacity

2. Outstanding separation effect (applied in liquid-liquid-solid separation)

3. Wide usage in the fish oil and fishmeal field

4. Corrosion resistant an resistant key parts

5. Flexible length-to-diameter model for customerized.

6. Famous and reliable electrical components

Separation range

A. When the liquid viscosity is small and the solid particle size is large, the specific gravity difference between solid, liquid and liquid is required to be ≥ 0.05g/cm3 (solid weight and liquid light).

B. When the liquid viscosity is small and the specific gravity difference between solid and liquid is large (specific gravity

difference ≥ 1g / cm3), the solid particle is required to be ≥ 0.005mm and the specific gravity difference between liquid and liquid is required to be ≥ 0.05g/cm3.

C. When the liquid viscosity is large or the specific gravity of solid-liquid is small and the solid particles are very fine, the

separation effect will be affected or even not applicable.

D. When the solid particles are easy to be damaged, the separation effect will also be affected.

B. When the liquid viscosity is small and the specific gravity difference between solid and liquid is large (specific gravity

difference ≥ 1g / cm3), the solid particle is required to be ≥ 0.005mm and the specific gravity difference between liquid and liquid is required to be ≥ 0.05g/cm3.

C. When the liquid viscosity is large or the specific gravity of solid-liquid is small and the solid particles are very fine, the

separation effect will be affected or even not applicable.

D. When the solid particles are easy to be damaged, the separation effect will also be affected.

PRODUCT CONFIGURATION

Components1

Components 2

Components 3

Application

Hot Searches