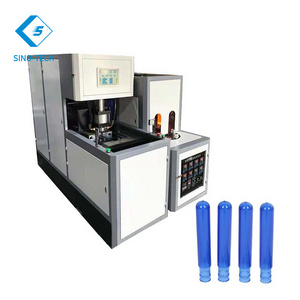

- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

3000 ml

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Lingma

-

Voltage:

-

380/220/110V

-

Dimension(L*W*H):

-

1.5x0.65x1.7m

-

Weight (KG):

-

1200 KG

-

Warranty:

-

1 year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Cavity number:

-

single or double cavities

-

Bottle volume:

-

2.5~3L(1 cavities)

-

Capacity:

-

400Pcs/H

-

Machine blowing:

-

two step semi automatic stretch blowing machine

-

Max. stretch length:

-

350mm

-

Max. mould thickness:

-

120-230mm

-

Mould clamping force:

-

80KN

-

Size of main pin:

-

100-220mm

Quick Details

-

Neck Diameter(mm):

-

45 mm

-

Max.Bottle Diameter(mm):

-

200 mm

-

Max.Bottle Height(mm):

-

350 mm

-

Bottle Volume(ml):

-

3000 ml

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Lingma

-

Voltage:

-

380/220/110V

-

Dimension(L*W*H):

-

1.5x0.65x1.7m

-

Weight (KG):

-

1200 KG

-

Warranty:

-

1 year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Cavity number:

-

single or double cavities

-

Bottle volume:

-

2.5~3L(1 cavities)

-

Capacity:

-

400Pcs/H

-

Machine blowing:

-

two step semi automatic stretch blowing machine

-

Max. stretch length:

-

350mm

-

Max. mould thickness:

-

120-230mm

-

Mould clamping force:

-

80KN

-

Size of main pin:

-

100-220mm

Famous features:

Famous features:

1.Advanced PLC control system with a use-friendly panel and time-control precision of PLC up to 0.01second

2.Equipped with special designed air storage unit ;Using Infrared preform heater.

3.Independent Temperature Control for different heating lamp to get ideal preform heating results; Heating lamps are adjustable in directions to suit various preforms

1.blowing and Pneumatic system: Simple operation and high control precision, bottle blow unit is equipped with specially designed PLC control system. It controls the whole bottle production process through a soft touch pad with time control precision up to 0.01 second; Pneumatic unit provides power for machine movements including machine driving and bottle blowing.

2.Clamping system:this adopts three-plate toggle clamping system to provide powerful clamping force required by high pressure blowing up to 35 bars. Besides, the system has an adjustment device to change the distance between front & middle mold-plate and the position of stretch-seal cylinder required in different mold installation

3.Heating system: QCL-12 series preform heater adopts infrared lamp as heating unit. Infrared has powerful thermal-radiation capacity, which can heat up preform to required temperature in a very short time, while the strong thermal-penetrability provides continuous and uniform heating inside of preform and on surface of the preform, and also adopts independent temperature control unit for each heating zone to offer ideal temperature for various preform. Each heating lamp has a voltage regulator to control the voltage of the heating lamps and keep it working smoothly. With the LED display, it becomes easy and convenient to inspect and adjust the voltage value.

4.Safety system: In order to keep both machine and operator safe, this machine installs twin startup switches on two sides of the machine, which should be pressed at the same time to start the machine, while there is also an emergency stop button on the machine to stop machine urgently if necessary.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.