we can promise to ship the goods in time.I stress this point because at present, the Chinese government has a very strict requirement for the factory, if the factory doesnt have a complete certificates for the production, they will face the problem to be closed. And this will affect the delivery time. And for Tonsen, we have get all the certificates so we never meet this problem.

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Capacity Request

-

Weight:

-

2000 KG

-

Name:

-

Mixing Tank With Agitator

-

Material:

-

SUS304/SUS316/Red copper

-

Heating method:

-

Steam/Electric/Direct fire

-

Control system:

-

Manual/Semi-automatic

-

Plate type:

-

Mirror polishing/2B/wire Drawing

-

Insulation:

-

Polyurethane/rockwool

-

QA & QC:

-

Yes

-

After Warranty Service:

-

Video technical support

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Tonsen

-

Voltage:

-

3P 380V/ 1P 220V (Other optional)

-

Dimension(L*W*H):

-

Capacity Request

-

Weight:

-

2000 KG

-

Name:

-

Mixing Tank With Agitator

-

Material:

-

SUS304/SUS316/Red copper

-

Heating method:

-

Steam/Electric/Direct fire

-

Control system:

-

Manual/Semi-automatic

-

Plate type:

-

Mirror polishing/2B/wire Drawing

-

Insulation:

-

Polyurethane/rockwool

-

QA & QC:

-

Yes

-

After Warranty Service:

-

Video technical support

Technical information

* Electric heating way or steam heating or without heating or with cooling jacket

* Insulation: Rock wool

* Insulation thickness: 80mm

* Material: SUS304, Brushed outer shell.

* Interior thickness: 3mm

* Exterior thickness: 2mm

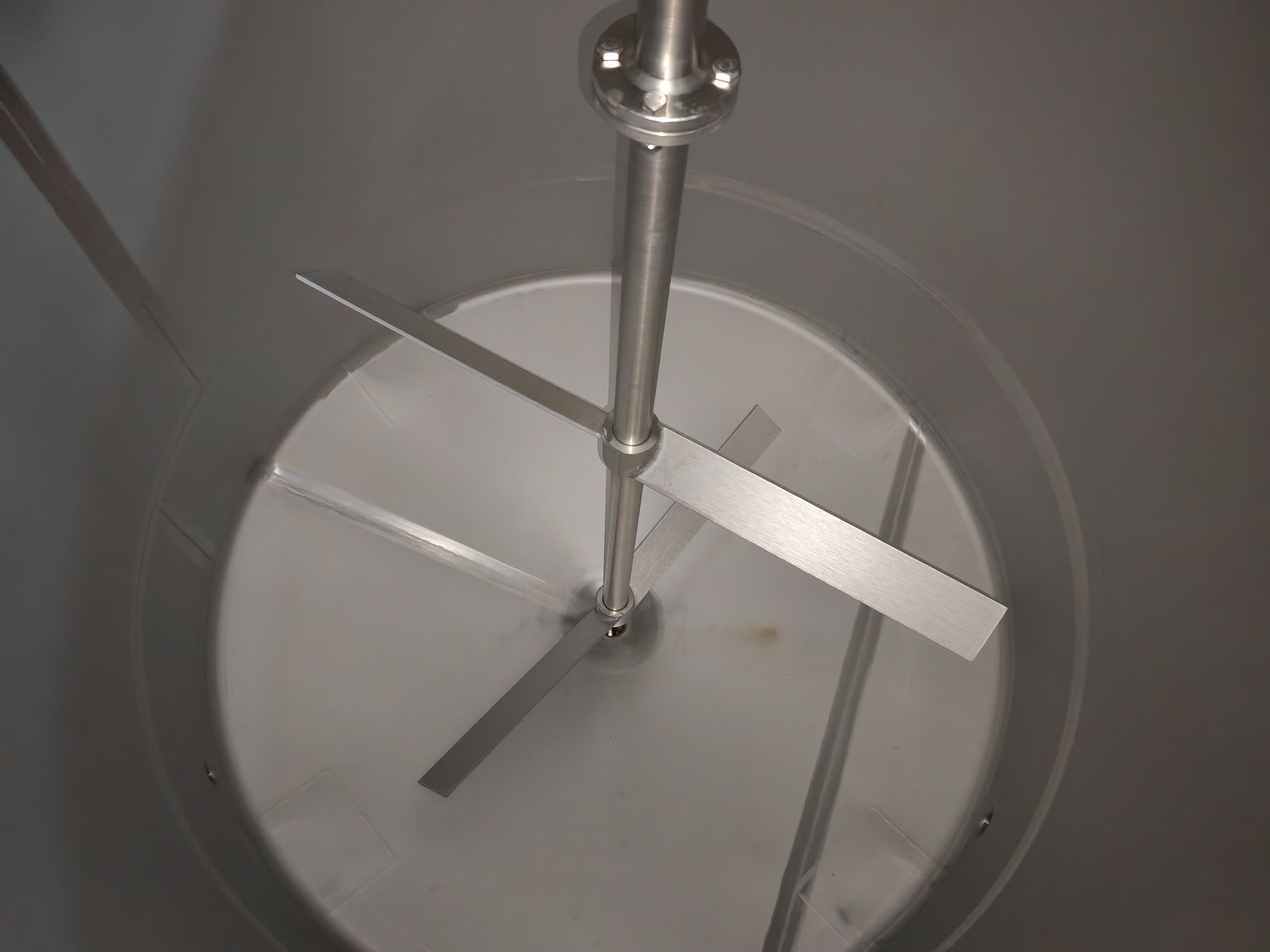

* Agitator with frequency conversiontopmotor

* Dished top and conical bottom

* Top mounted Manhole

* Liquor level side tube

* CIP 360°rotary spray device

* Temperature sensor PT100

* Interior Finish: Completely acid washing and passivation, inside polishing to 0.6μm without dead corner

* Plate Surface protection, ribbon polished on welds.

* 100%TIG welding with pure argon gas shield

* 4pcs completely SUS304 heavy duty legs with leveling pad

* With all matched valves and accessories.

With control panel

|

Capacity/batch

|

100L

|

200L

|

300L

|

500L

|

1000L

|

|

Model

|

TS-100L

|

TS-200L

|

TS-300L

|

TS-500L

|

TS-1000L

|

|

Area

|

15M2

|

25M2

|

35M2

|

45M2

|

80M2

|

|

Power

|

8kw

|

12kw

|

20kw

|

35kw

|

35/15kw

|

|

Frementation cycle

|

8~20days

|

8~20days

|

8~20days

|

8~20days

|

8~20days

|

2) All accessories and spare parts will be packed with soft protection material and then put into iron box

3) After loaded into containers, all equipment will be fixed to the containers.

Technical Drawing

Layout design

3D Drawing

2.Lifetime repair guarantee.

3.All spare parts and wearing parts are attached with the machinery for free.

SERVICE

2.Project planning and design the layout service.

3.Free debugging instruction of equipment until everything is functional.

4.Management of equipments' long distance shipping from seller's factory to named pord or station by buyer.

5.Training of equipment maintenance and operation personally.

6.New production techniques.