- Product Details

- {{item.text}}

Quick Details

-

MF:

-

N/A

-

EINECS No.:

-

N/A

-

Place of Origin:

-

Shanghai, China

-

Type:

-

Cleaning agent

-

Brand Name:

-

VCI

-

Model Number:

-

VCI-601

-

Product name:

-

Low Foam Water Based Cleaning Agent

-

Model:

-

VCI-601

-

Application:

-

Used for automobile industry

-

Appearance:

-

Light yellow transparent liquid

-

Keywords:

-

Cleaning agent

-

Function:

-

Oil cleaning and rust remover

-

Size:

-

200L/barrel

-

Packing:

-

Iron drum

-

Density:

-

1.20±0.05

-

Viscosity:

-

0.98

Quick Details

-

CAS No.:

-

N/A

-

Purity:

-

N/A

-

Other Names:

-

N/A

-

MF:

-

N/A

-

EINECS No.:

-

N/A

-

Place of Origin:

-

Shanghai, China

-

Type:

-

Cleaning agent

-

Brand Name:

-

VCI

-

Model Number:

-

VCI-601

-

Product name:

-

Low Foam Water Based Cleaning Agent

-

Model:

-

VCI-601

-

Application:

-

Used for automobile industry

-

Appearance:

-

Light yellow transparent liquid

-

Keywords:

-

Cleaning agent

-

Function:

-

Oil cleaning and rust remover

-

Size:

-

200L/barrel

-

Packing:

-

Iron drum

-

Density:

-

1.20±0.05

-

Viscosity:

-

0.98

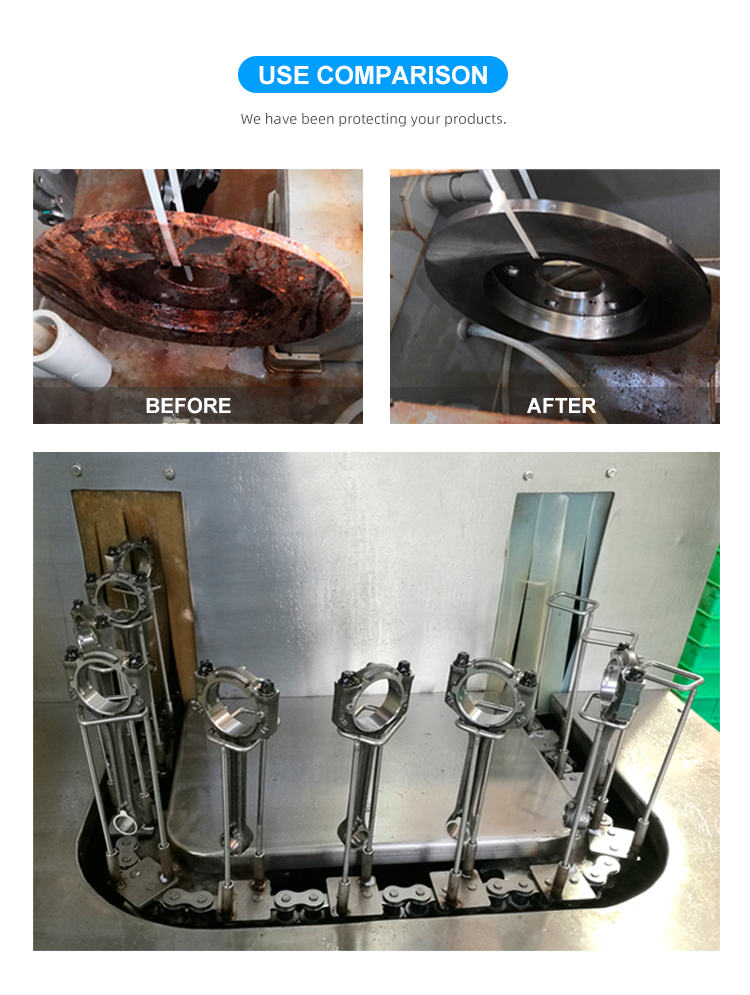

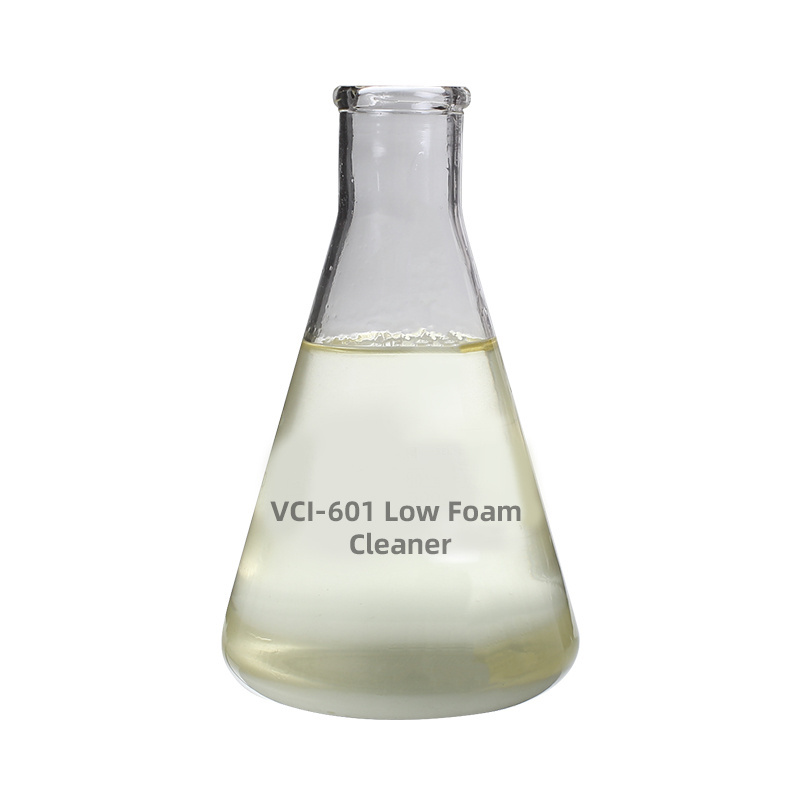

VCI-601 Low Foam Water Based Cleaning Agent

VCI-601 Low Foam Water Based Cleaning Agent is a environmentally friendly water based cleaning agent which is composed of low foam surfactant, osmotic diffusion agent, anti-rust agent and high quality cleaning agent. No heavy metals, phosphorus, nitrite and other controlled substances. Green, harmless, completely biodegradable.

- Application

It is used for cleaning the machine oil, lapping oil, cutting fluid, antirust oil, dust and other pollutants on the nonferrous metal parts surface of ferrous metal, stainless steel, copper, aluminum, magnesium, zinc and alloy.

- Main feature

1. Low foam or even no foam, especially suitable for high pressure spray cleaning. Alkalescence, high enrichment, strong oil removal ability, can quickly remove all kinds of oil and dirt on the surface of the workpiece, clean ability ≥ 99% .

2. Has a strong permeability, dispersion, solubilization, emulsification.

3. Less dosage, dissolve completely, long service life, easy to rinse. At the same time, it can effectively protect the surface of the cleaned material from erosion. It has the function of short term antirust in the case of no water rinsing after cleaning.

4. Green, environmentally friendly, efficient, security, economical.

- Main technical parameters

|

Product Name/Model |

VCI-601 Low Foam Water Based Cleaning Agent |

|

Outlook |

Light yellow transparent liquid, no pungent smel |

|

Density (g/ cm3) |

1.20±0.05 |

|

Viscosity (@40℃mPa.s) |

0.98 |

|

Material compatibility test |

It has no effect on steel, copper, aluminum, stainless steel, ceramics, plastics, glass, etc. |

|

PH value (original liquid) |

7.0~10.0 (5% concentration) |

|

Poisonous and harmful check |

Harmless, nonirritating reaction |

|

Biodegradation |

Completely biodegradable |

- Usage

1. Please read the instructions carefully before using this product , and under the guidance of professionals for use. Cleaning methods can be spray, hot soaking, ultrasonic cleaning, manual wiping and so on.

2. When using, adjust the concentration of cleaning fluid according to the severity of the oil. In order to get the best cleaning effect, generally the original solution and water are prepared into a concentration of 5~8% cleaning solution, after warm up to 55~80℃, spray cleaning or ultrasonic cleaning for 3~10 minutes, wash the workpiece with clean water before drying or drying directly. The cleaning ability can be improved by increasing the concentration of cleaning fluid. The concentration of cleaning agent should be relatively high when cleaning by hand.

3. In case of heavy oil or grease with high dissolving point, part of the oil sludge should be removed manually or mechanically before cleaning .

- Matters need attention

1. Adjust the concentration of cleaning fluid according to the weight of oil, after cleaning the workpiece depends on its surface cleanliness requirements to determine the subsequent processing of the workpiece.

2. Remove the oil slick on the surface of the tank in time to avoid secondary pollution.

3. 1%~3% cleaning agent should be added regularly everyday. If the cleaning capacity cannot reach the original level after replenishment, a new liquid can be discarded.

4. Do not make contact with eyes. If accidentally splashes into the eye, may lift the eyelid, with flowing water or physiological saline rinse clean. Do not swallow this product, if swallowed, do not induce vomiting, stay at rest, timely medical treatment.

5. To prevent excessive degreasing of the skin, wear chemical resistant gloves when operating.

- Waste water treatment

It doesn't have any impact on the environment. The waste water after cleaning can be directly discharged into industrial pipelines after treatment.

- Packing and storage

Packing: 200L

Storage: sealed storage in cool, dry and ventilated place, shelf life 2 years.