- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

Other

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

qingke

-

Weight (KG):

-

1700 kg, 1700

-

depth:

-

60cm

-

width:

-

60cm

-

Material speed:

-

1.25m/min

-

Lining walking speed:

-

1.2m~1.5m/min

-

Lining speed:

-

5-11m/h

-

Lining thickness:

-

60-160mm

-

power:

-

70.5kw

-

Color:

-

Customer's Demand

-

Keywords:

-

Easy Operation Block Making Machine

Quick Details

-

Type:

-

Interlock Block Making Machine, Other, Autoclaved aerated concrete block (AAC)

-

Brick Raw Material:

-

CONCRETE

-

Production Capacity (Pieces/8 hours):

-

Other

-

Brick size:

-

Other

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

qingke

-

Weight (KG):

-

1700 kg, 1700

-

depth:

-

60cm

-

width:

-

60cm

-

Material speed:

-

1.25m/min

-

Lining walking speed:

-

1.2m~1.5m/min

-

Lining speed:

-

5-11m/h

-

Lining thickness:

-

60-160mm

-

power:

-

70.5kw

-

Color:

-

Customer's Demand

-

Keywords:

-

Easy Operation Block Making Machine

Product Description

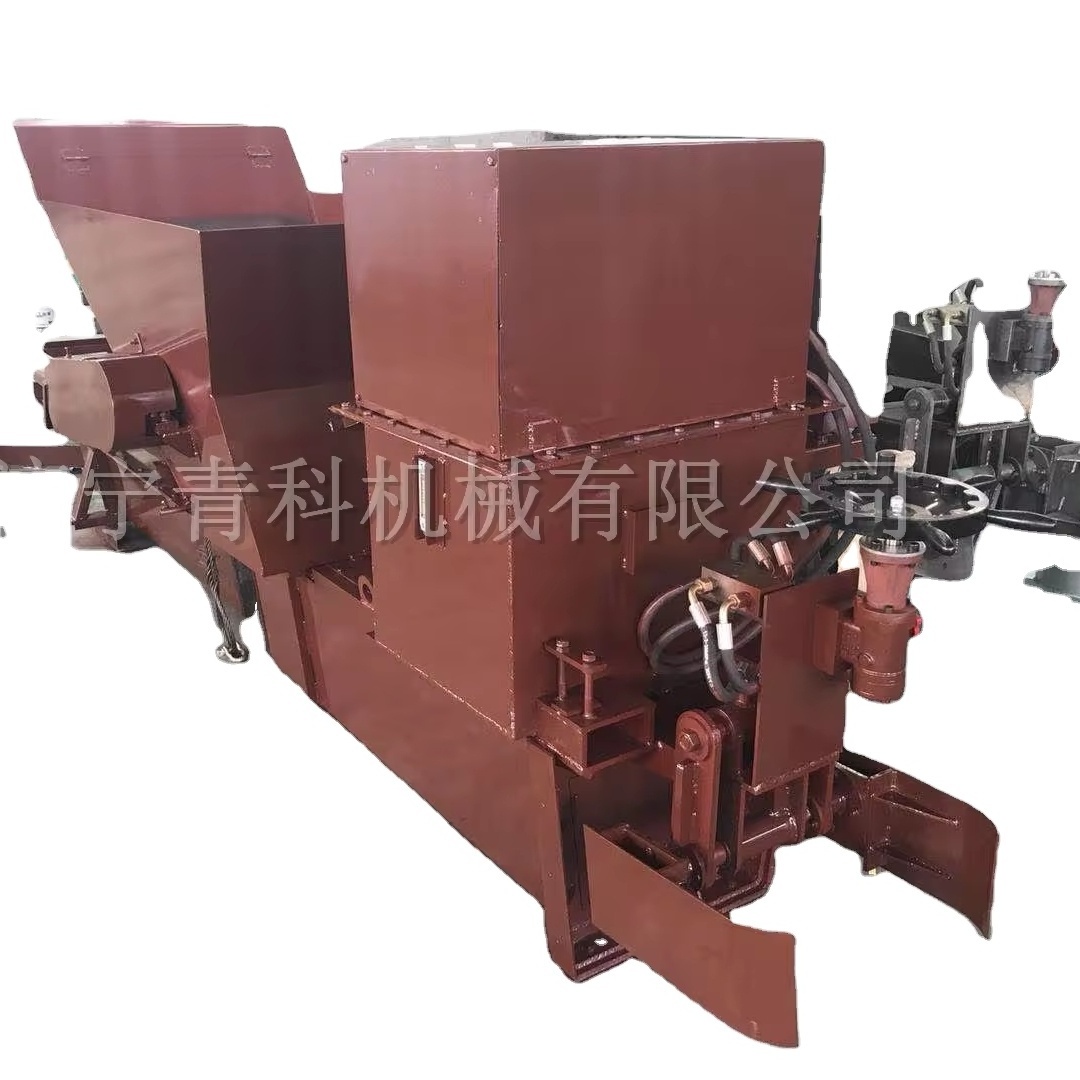

Customized Water Conservancy Engineering Equipment U-Shaped Concrete Channel Lining Machine

Introduction:

The canal bottom lining machine consists of four parts: feeding machine, spreading machine, smoothing machine and noodle collecting frame. The loading machine is placed on the canal slope, and the frame is connected to the spreading machine frame. There are running wheels at the bottom of the frame, so no traction is required and the walking is automatically controlled. The spreading machine, smoothing machine, and noodle collecting rack are placed parallel to each other at the bottom of the ditch, with a certain distance between them. The material is put into the hopper of the loading machine from the tanker, and then sent to the hopper of the spreader along with the belt. Then it is fed along the belt of the spreader. The material is introduced into the storage hopper through the baffle plate on the belt, and is spread by the vibrating plate under the frame. Evenly, then smooth it with a trowel, and then manually close the dough with the noodle closing machine.

Product Performance

|

Product Name

|

Customized Water Conservancy Engineering Equipment U-Shaped Concrete Channel Lining Machine

|

|

Material speed

|

1.25m/min

|

|

Condition

|

New

|

|

Warranty

|

1 Year

|

|

power

|

70.5kw

|

|

Machinery Test Report

|

Provided

|

|

Video outgoing-inspection

|

Provided

|

|

Material speed

|

1.25m/min

|

|

Lining speed

|

5-11m/h

|

|

Lining thickness

|

60-160mm

|

Hot Searches