- Product Details

- {{item.text}}

Quick Details

-

Power:

-

76 KW

-

Weight:

-

36000 kg

-

MODEL:

-

YLB1000

-

Productivity:

-

80t/h

-

Total Power:

-

242 kw

-

Cold Bin:

-

4*7 m³

-

Drying Capacity:

-

90t/h

-

Dryer Drum Size:

-

1600*6800

-

Screw conveyor Capacity:

-

15t/h

-

Bitumen Tank:

-

40 m³

-

Mixer Capacity:

-

1000 kg

-

Mixing Power:

-

2*18.5 kw

Quick Details

-

Machine Type:

-

Batching machine

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Top Brand

-

Power:

-

76 KW

-

Weight:

-

36000 kg

-

MODEL:

-

YLB1000

-

Productivity:

-

80t/h

-

Total Power:

-

242 kw

-

Cold Bin:

-

4*7 m³

-

Drying Capacity:

-

90t/h

-

Dryer Drum Size:

-

1600*6800

-

Screw conveyor Capacity:

-

15t/h

-

Bitumen Tank:

-

40 m³

-

Mixer Capacity:

-

1000 kg

-

Mixing Power:

-

2*18.5 kw

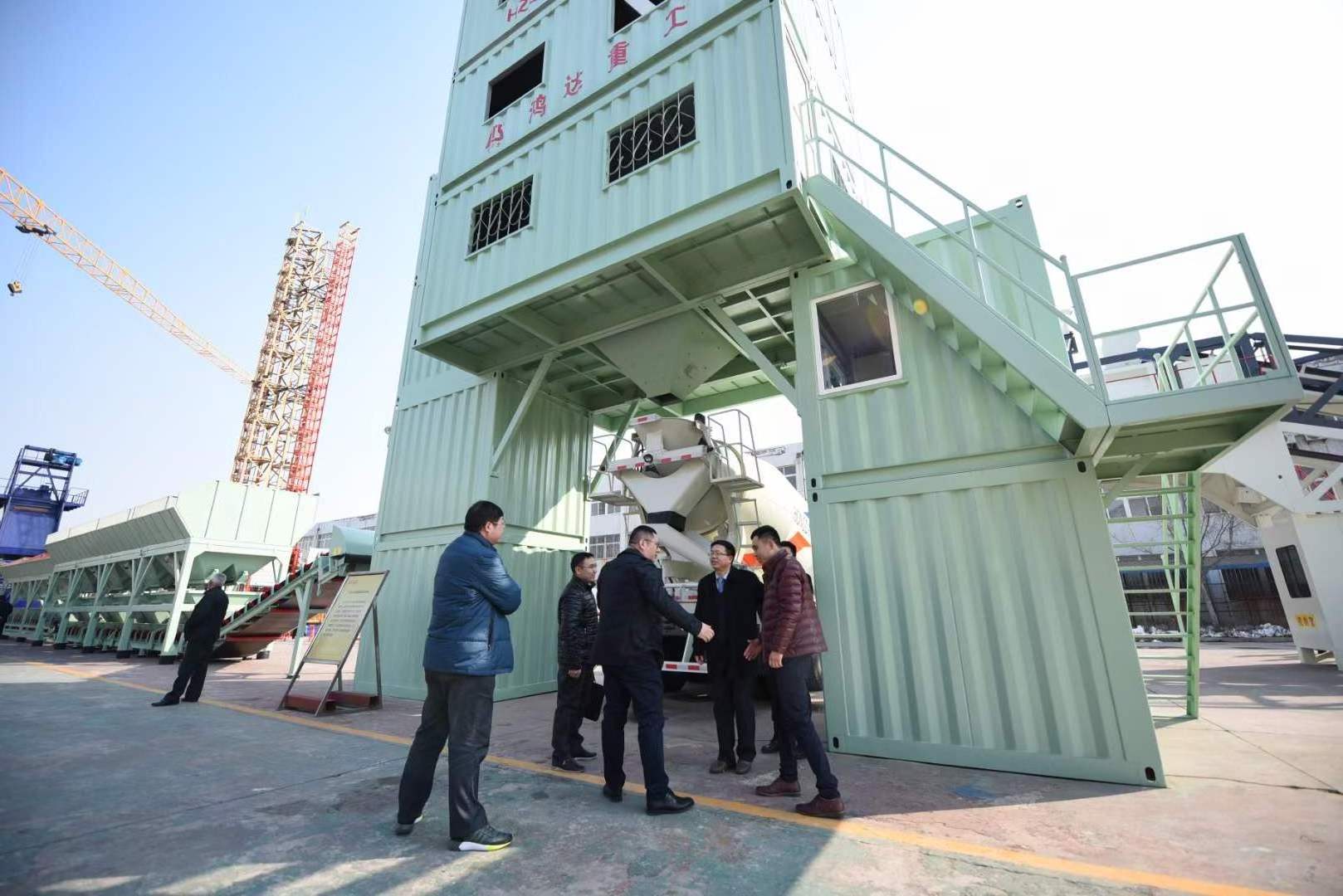

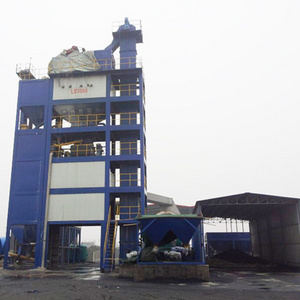

YLB1000 asphalt concrete for road construction mobile asphalt mixing plant

Contact Way

Product Overview

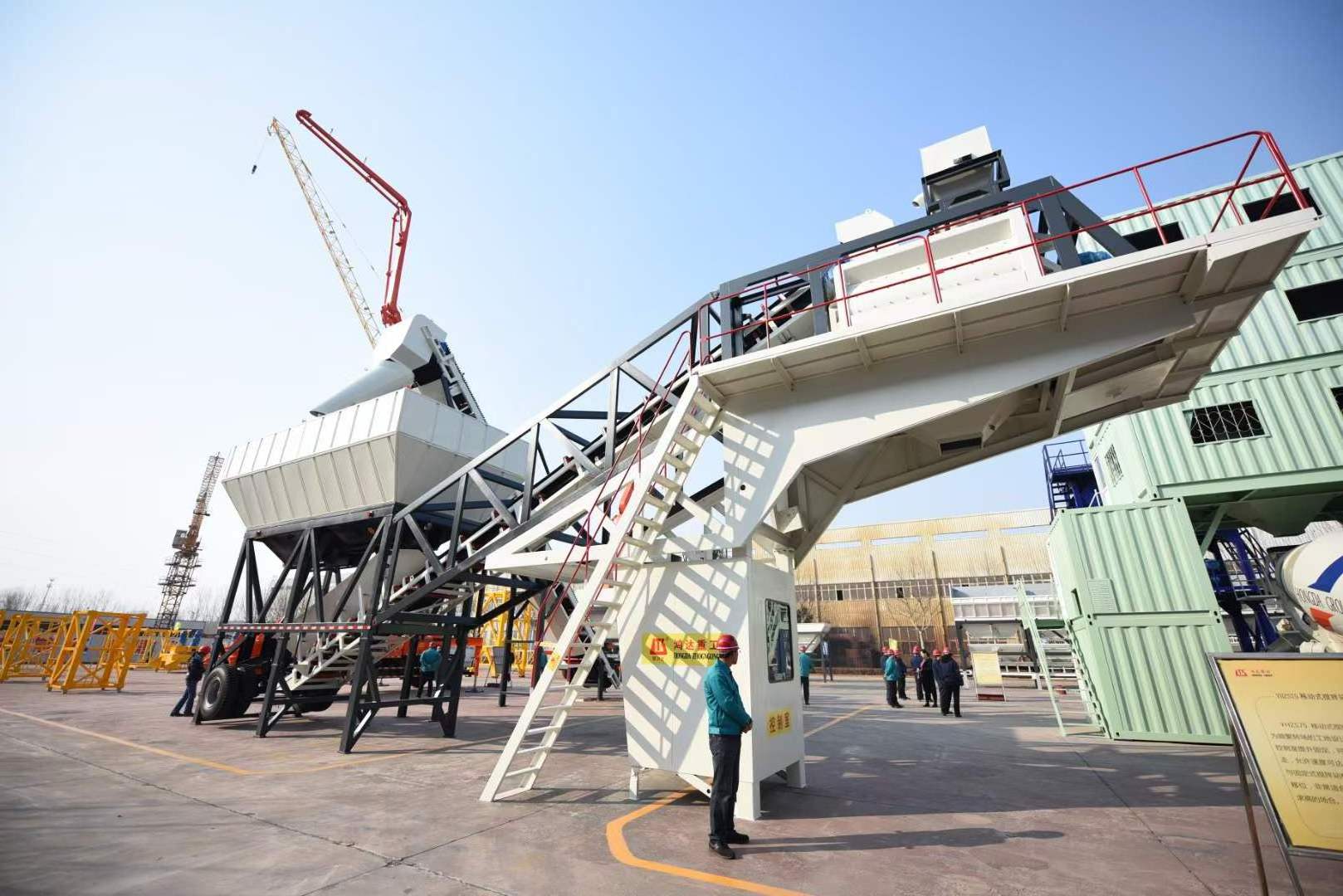

1. The original modular design of the mixing plant makes transport and installation work quick and convenient.

2. The loop belt feeder for the measuring hopper has a variable frequency speed controller which can provide high and low speed. Its original structure facilitates belt change and makes material feeding more fluent, which reduces power consumption. Besides, there is a warning light which will remind the user when the machine uses up raw material.

3. The high-efficiency and heat-preservation drying drum and the special vanes make heat exchange more sufficient. Moreover, the high-efficiency and energy-saving imported burner can use both heavy oil and diesel, which reduces energy consumption.

4. The vibrating screen adopts the linear and completely-closed design with the vibrator placed outside. The sieving efficiency is high, the maintenance and changing of screen is easy, and the imported bearings are more reliable.

5. The hot aggregate bin is equipped with a continuous level indicator which enables the operator to know the level of material at a glance. The measurement of aggregate is conducted twice through large and small doors, which greatly improves the measuring precision. The unique structure of the material emptying door reduces the chance of blockage and will work more reliably.

2. The loop belt feeder for the measuring hopper has a variable frequency speed controller which can provide high and low speed. Its original structure facilitates belt change and makes material feeding more fluent, which reduces power consumption. Besides, there is a warning light which will remind the user when the machine uses up raw material.

3. The high-efficiency and heat-preservation drying drum and the special vanes make heat exchange more sufficient. Moreover, the high-efficiency and energy-saving imported burner can use both heavy oil and diesel, which reduces energy consumption.

4. The vibrating screen adopts the linear and completely-closed design with the vibrator placed outside. The sieving efficiency is high, the maintenance and changing of screen is easy, and the imported bearings are more reliable.

5. The hot aggregate bin is equipped with a continuous level indicator which enables the operator to know the level of material at a glance. The measurement of aggregate is conducted twice through large and small doors, which greatly improves the measuring precision. The unique structure of the material emptying door reduces the chance of blockage and will work more reliably.

Product Paramenters

|

Items

|

Configuration

|

QTY

|

Performance

|

|

1. Batching System

|

Cold Aggregate Bin (6m3, with Filter Screen)

|

4

|

Feeding Ability of Single Belt Conveyor: 60T/h (frequency-converting Speed Control);

|

|

|

Aggregate Output Belt Conveyor

|

4 set(s)

|

|

|

|

Belt (500mmx3m)

|

4 piece(s)

|

Conveying Ability of Aggregate Belt Conveyor:

|

|

|

Variable-frequency Electric Roller (1.1kw)

|

4 set(s)

|

≥80 T/h

|

|

|

Approach Switch

|

4 set(s)

|

(with NO-Material Warning System)

|

|

|

Rotating Warning Light

|

4 set(s)

|

|

|

|

Aggregate Belt Conveyor

|

1 set(s)

|

|

|

|

Belt (500mmx36m)

|

1 piece(s)

|

|

|

|

Guard Board

|

1 set(s)

|

|

|

|

Electric Roller (4kw)

|

1 set(s)

|

|

|

|

Vibrator MVE200/3

|

1 set(s)

|

|

|

2. Burning System

|

Burner

|

1 set(s)

|

Max Oil Consumption: 550L/h

|

|

|

Oil Supply Pipeline and Stander

|

1 set(s)

|

Fuel: Diesel or Heavy Oil

|

|

|

Automatic Temperature Control system

|

1 set(s)

|

|

|

3. Rotary Drying Drum

|

Rotary Drying Drum (φ1500×6200)

|

1 set(s)

|

Drying ability:≥80T/h

|

|

|

Stander, Idler Roller, Guard Roller, etc.

|

1 set(s)

|

|

|

|

Feeding Box

|

1 piece(s)

|

|

|

|

Discharging Box

|

1 piece(s)

|

|

|

|

Speed-down Motor (22kw)

|

1 set(s)

|

|

|

|

Heavy-duty Chains

|

1 set(s)

|

|

|

4. Hot Aggregate Hoisting Machine

|

Top Bin Body, Bottom Bin Body, Mast section, Lift Hopper, Ladder, Platform Guardrails, etc.

|

1 set(s)

|

Hoisting Ability:≥80T/h

|

|

|

Plate-type Chains

|

|

|

|

|

Anti-reversion Speed-down Motor

|

|

|

|

5. Vibrating Sieve

|

Closed-type Round Vibrating Sieve (4- layer)

|

1 set(s)

|

Sieving Productivity:80T/h

|

|

6. Hot Aggregate Storage Bin

|

Bin Body, Ladder, Platform, etc.

|

1 piece(s)

|

With Sample Collection and Overflow Pipe

|

|

|

Upper and Lower Paddle Switch Level Indicators

|

4 piece(s)

|

|

|

|

(High Temperature Resistant)

|

|

|

|

|

Thermal Resistance for Temperature Control

|

1 set

|

|

|

|

Cylinder with Valve (φ100)

|

4 set(s)

|

|

|

7. Aggregate Measuring System

|

Measuring Hopper

|

1 piece(s)

|

Measuring Range:0~1500kg

|

|

|

Weighing Transducer

|

3 piece(s)

|

Measuring Precision:±0.50%

|

|

|

Cylinder with Valve (φ100)

|

1 piece(s)

|

|

|

8. Powder Measuring System

|

Weighing Hopper

|

1 piece(s)

|

Measuring Range:0~250kg

|

|

|

Weighing Transducer

|

1 set(s)

|

Measuring Precision:±0.35%

|

|

|

Pneumatic Butterfly Vale

|

1 set(s)

|

|

|

|

Screw Conveyor

|

1 set(s)

|

|

|

|

Vibrator MVE60

|

1 set(s)

|

|

|

9. Asphalt Measuring System

|

Weighing Box (heated by conduction oil,with insulating layer)

|

1 piece(s)

|

|

|

|

Metal Hose

|

1 set(s)

|

Measuring Range:0~250kg

|

|

|

Weighing Transducer

|

1 piece(s)

|

Measuring Precision:±0.25%

|

|

|

Asphalt Spraying Pump

|

1 set(s)

|

|

|

10. Main Mixer

|

Main Mixer

|

1 set(s)

|

Mixing Ability:1000kg/batch

|

|

|

Reducer

|

1 set(s)

|

|

|

|

Electric Motor (18.5 kw)

|

2 set(s)

|

Filling Rate: 50%

|

|

|

Framework for the Weighing and Mixing Units, Staircase, Platform, etc.

|

1 set(s)

|

|

|

|

Limit Switch

|

1 set(s)

|

Mixing Cycle:45S

|

|

|

Cylinder with Valve (φ100)

|

2 set(s)

|

Forced Asphalt Spraying

|

|

|

Air Compressor

|

1 set(s)

|

Air Flow:1.5m3/min

|

|

11. Pneumatic System

|

Air Storage Tank (0.6m3)

|

1 set(s)

|

Air Pressure:0.7MPa

|

|

|

Electromagnetic Valve

|

1 set(s)

|

|

|

|

Pneumatic Trio, Pneumatic Double Unit

|

2 piece(s)

|

|

|

|

Pipeline System

|

1 set(s)

|

|

Details Images

Sales and Service Network

Hot Searches