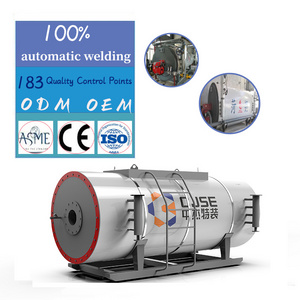

SZS type oil-fired gas

fired steam

boiler is a

high-efficiency, energy-saving and environmentally friendly double-drum vertical boiler, which is especially loved by customers in the central heating of industries, enterprises and schools. This type of boiler is composed of pressure components such as upper drum, lower drum, water wall tubes, convection tube bundles and headers. The upper and lower drums are placed vertically on the same vertical plane. The furnace body is made of high thermal resistance material as the thermal insulation layer, which has excellent thermal insulation performance. Overpressure protection, explosion-proof door protection, etc., fully ensure the smooth operation of the boiler.

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

7700*2750*3750

-

Weight:

-

30.6t

-

Name:

-

Automatic Horizontal Gas Oil Fired Steam Boiler

-

Rated steam pressure::

-

0.7Mpa-2.5Mpa

-

Steam Capacity:

-

4-150t

-

After-sales Service Provided:

-

Online Service

-

Rated Steam temperature::

-

170-250

-

Design fuel:

-

OIL GAS

-

Application:

-

Industrial Requiring Steam

-

Certification:

-

ISO CE certificate

Quick Details

-

Core Components:

-

boiler

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yongxing

-

Dimension(L*W*H):

-

7700*2750*3750

-

Weight:

-

30.6t

-

Name:

-

Automatic Horizontal Gas Oil Fired Steam Boiler

-

Rated steam pressure::

-

0.7Mpa-2.5Mpa

-

Steam Capacity:

-

4-150t

-

After-sales Service Provided:

-

Online Service

-

Rated Steam temperature::

-

170-250

-

Design fuel:

-

OIL GAS

-

Application:

-

Industrial Requiring Steam

-

Certification:

-

ISO CE certificate

Products Description

SZS type oil-fired gas fired steam boiler

Product Paramenters

|

Boiler model

|

|

|

SZS10

|

SZS15

|

SZS20

|

SZS25

|

SZS30

|

SZS35

|

|||||||

|

Rated steam capacity

|

|

T/H

|

10

|

15

|

20

|

25

|

30

|

35

|

|||||||

|

Rated steam pressure

|

|

Mpa

|

1.25/1.6/2.5/3.82

|

|

|

|

|

|

|||||||

|

Rated steam temperature

|

|

℃

|

194/204/226/450

|

|

|

|

|

|

|||||||

|

Feed water temperature

|

|

℃

|

20/104

|

|

|

|

|

|

|||||||

|

Thermal efficiency

|

|

%

|

>98%

|

|

|

|

|

|

|||||||

|

Fuel type

|

|

light diesel oil/natural gas/heavy oil/liquefied gas/city gas

|

|

|

|

|

|

|

|||||||

|

Fuel consumption |

diesel oil

|

kg/h

|

618

|

927

|

1256

|

1545

|

1856

|

2470

|

|||||||

|

|

Natural gas

|

Nm3/h

|

660

|

987

|

1316

|

1660

|

1981

|

2630

|

|||||||

|

Max transporation size |

|

mm |

7870*3400

*3400 |

8900*3400

*3400 |

9300*3900

*4000 |

10500*4120

*4150 |

10500*4300

*4230 |

12330*4400

4530 |

|||||||

|

Max transporation weight

|

|

t

|

36.0

|

45.0

|

52.6

|

55.3

|

63.7

|

77.4

|

|||||||

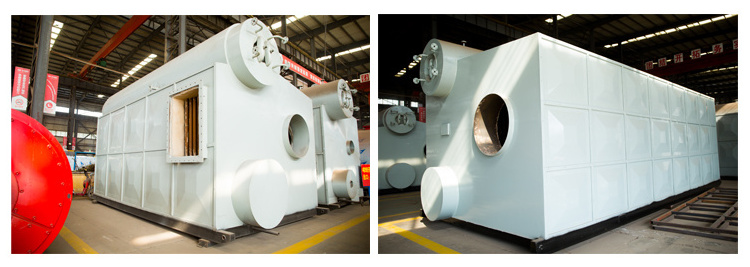

Details Images

PERFORMANCE CHARACTERISTICS-- Industrial Steam Boiler

●D-type layout, compact structure, small size, good flame fullness

●The front and rear walls all adopt membrane water-cooled wall structure to ensure the service life of more than 20 years

●The arrangement of manholes in the front and back of the upper and lower drums and the inspection door at the rear of the boiler facilitate the user's maintenance and cleaning of the interior and exterior

PERFORMANCE CHARACTERISTICS-- Double Drum Large Capacity Steam Boiler

●Micro-positive pressure combustion improves the thermal efficiency of the boiler and reduces operating costs

●Reliable water circulation system to ensure that no vaporization water hammer occurs in the pipe

●The arrangement of explosion-proof doors and flame detectors makes the boiler safe and reliable in operation

●The thermal insulation layer of the boiler is made of high thermal resistance material, which has good thermal insulation performance

●Reliable water circulation system to ensure that no vaporization water hammer occurs in the pipe

●The arrangement of explosion-proof doors and flame detectors makes the boiler safe and reliable in operation

●The thermal insulation layer of the boiler is made of high thermal resistance material, which has good thermal insulation performance

PERFORMANCE CHARACTERISTICS-- Oil Gas Fuel Steam Boiler

●The appearance adopts concave-convex guard plate, which not only ensures the goodness of the overall sealing of the boiler, but also beautifies the appearance quality

●The three-pass convection tube bundle design prolongs the time for the flue gas to stay in the furnace, which makes the fuel burn more fully and improves the combustion efficiency

●The boiler adopts a fully automatic burner, and its combustion efficiency is higher than that of traditional boilers. In

particular, the protection functions such as overpressure and flameout improve the safety of workers' operation

●The three-pass convection tube bundle design prolongs the time for the flue gas to stay in the furnace, which makes the fuel burn more fully and improves the combustion efficiency

●The boiler adopts a fully automatic burner, and its combustion efficiency is higher than that of traditional boilers. In

particular, the protection functions such as overpressure and flameout improve the safety of workers' operation

Hot Searches