- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

vibrating sieve shaker machine

-

Motor:

-

Vertical Vibrating Motor

-

Layer(s):

-

1-4

-

Material:

-

Contact material stainless steel 304, all stainless steel 304

-

Surface Treament:

-

Mirror polishing, brushed polishing, spray painting

-

Diameter(mm):

-

400-2000

-

Model:

-

S49-B

-

Mesh Size (mesh):

-

3-500

-

Cleaning system:

-

Bounce ball, ultrasonic

-

Used for:

-

food industry

Quick Details

-

Type:

-

Circular

-

Place of Origin:

-

henan

-

Weight:

-

200 KG

-

Product name:

-

vibrating sieve shaker machine

-

Motor:

-

Vertical Vibrating Motor

-

Layer(s):

-

1-4

-

Material:

-

Contact material stainless steel 304, all stainless steel 304

-

Surface Treament:

-

Mirror polishing, brushed polishing, spray painting

-

Diameter(mm):

-

400-2000

-

Model:

-

S49-B

-

Mesh Size (mesh):

-

3-500

-

Cleaning system:

-

Bounce ball, ultrasonic

-

Used for:

-

food industry

Product Description

Introduction of vibrating sifter

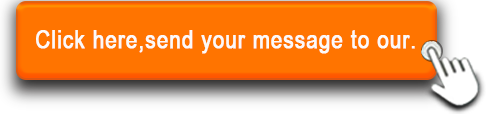

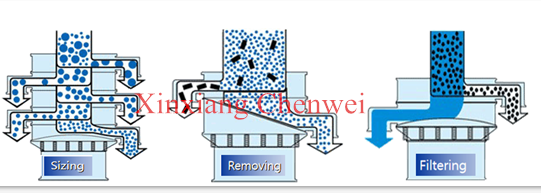

Rotary vibrating screen is a circular screening equipment with grading, impurity removal and liquid separation functions.

Different layers have different functions

Different materials are suitable for different materials

Application

1.

Chemical industry

: resin, pigment, cosmetic, coatings, Chinese medicine powder

2. Food industry : sugar powder, starch, salt, rice noodle, milk powder, egg powder, sauce, syrup

3.Metallurgy, Mine industry : aluminum powered, copper powder, ore alloy powder, welding rod powder

4.Medicinal industry : all kinds of medicine

5.Waste treatment : disposed oil, disposed water, disposed dye waste water, active carbon

2. Food industry : sugar powder, starch, salt, rice noodle, milk powder, egg powder, sauce, syrup

3.Metallurgy, Mine industry : aluminum powered, copper powder, ore alloy powder, welding rod powder

4.Medicinal industry : all kinds of medicine

5.Waste treatment : disposed oil, disposed water, disposed dye waste water, active carbon

Size Information

|

Model

|

Diameter(mm)

|

Deck

|

Effective diameter

|

Power(kw)

|

Maximum material size to process(mm)

|

|

S494-B

|

400

|

1-4

|

380

|

0.25

|

20

|

|

S496-B

|

600

|

1-4

|

600

|

0.6

|

20

|

|

S498-B

|

800

|

1-4

|

750

|

0.6

|

30

|

|

S4910-B

|

1000

|

1-5

|

900

|

0.8

|

30

|

|

S4912-B

|

1200

|

1-5

|

1100

|

1.5

|

30

|

|

S4915-B

|

1500

|

1-4

|

1450

|

2.2

|

50

|

|

S4918-B

|

1800

|

1-3

|

1750

|

2.5

|

50

|

|

S4920-B

|

2000

|

1-3

|

1950

|

2.5

|

60

|

Note: the above table data is for reference only, and the specific configuration is mainly based on the scheme designed by the engineer

Customer site

Machine Show

Packing & Delivery

Our Service

Our Company

Xinxiang Chenwei Machinery Co., Ltd. is an innovative enterprise that integrating technology R&D, processing, manufacturing and trade services. Our company is mainly devoted ourselves to the design, fabrication and installation of screening, conveying, mixing, crushing and other related products.

Our Company

FAQ

Q: What information do we need to help you choose a perfect machine? 1. Name and feature of the raw material 2.Aim of using: get rid of impurity, filtration, grading 3.Handling capacity: kg /h, L/h 4.The raw material size: (mesh or mm) 5.How many layers you need? 6.The voltage , frequency , phase (single or three) Note: You'd better send us the relevant pictures or some materials you want to sift , it can assure us to recommend the suitable machine for you. Q:Can I ask some special and customize design? A: Yes, we can make a suitable machine for you according to your request. Q:What is the real delivery time of your factory? A: 7 to 15 days for general series products, meanwhile, batches products & customized products would need 30 days to 60 days based on different.

Hot Searches