- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Sugar Mill, Paper, Industry, Energy

-

Function:

-

Heat exchanger

-

Certification:

-

ISO, ASME, EN

-

Color:

-

Red / Blue / Grey

-

Packaging:

-

Iron Frame Package

-

Temperature:

-

High temperature

-

Port:

-

Shanghai

-

After Warranty Service:

-

Spare parts

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

HD BOILER

-

Material:

-

Stainless Steel, Carbon Steel, Alloy Steel

-

Application:

-

Sugar Mill, Paper, Industry, Energy

-

Function:

-

Heat exchanger

-

Certification:

-

ISO, ASME, EN

-

Color:

-

Red / Blue / Grey

-

Packaging:

-

Iron Frame Package

-

Temperature:

-

High temperature

-

Port:

-

Shanghai

-

After Warranty Service:

-

Spare parts

Products Description

Introduction

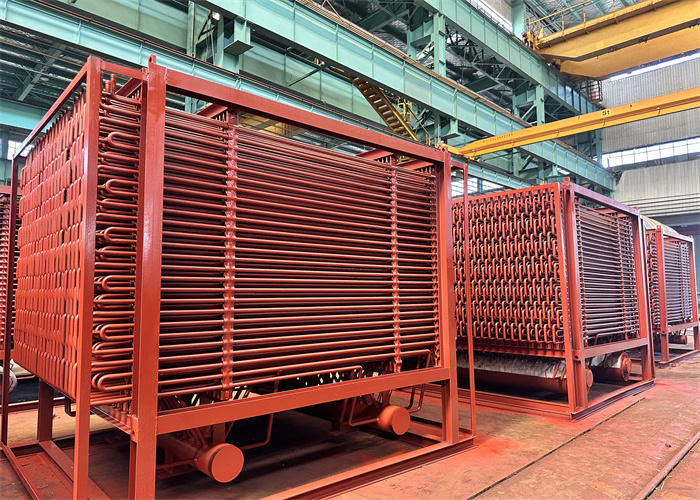

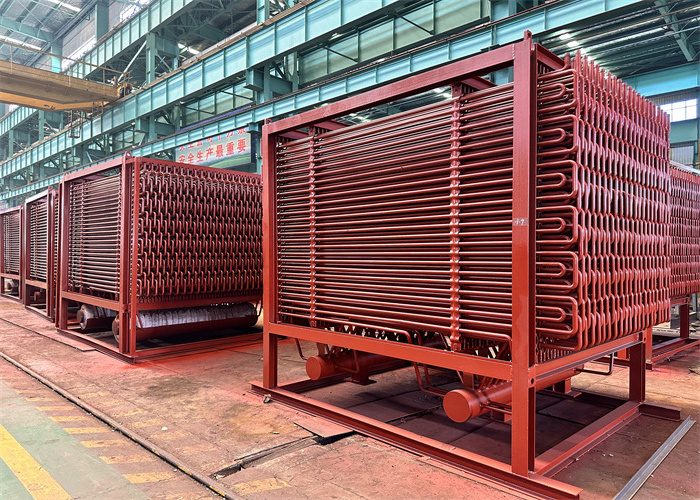

Boiler economizers are heat exchange devices with finned tubes that heat a liquid, sometimes water, up to however sometimes doesn't exceed the boiling purpose of liquid. We can manufacture three types of boiler economizer, bare tube economizer, H finned tube economizer and spiral finned tube economizer. H-finned tube economizer is high efficient heat exchanger economizer which is consisted of H-finned tubes.

Compared with bare tube economizer, H-finned tube economizer can enlarge the heat exchange area and reduce the number of tubes. It also can increase the flue gas flow area in order to reduce the flue gas flow speed and abrasion.

H-finned tube can be made as double H finned tubes , with high rigidness to fit long tube row.

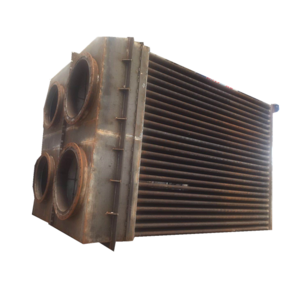

The spiral finned economizer is a newly designed heat transfer equipment, consists of spiral fin tubes to overcome the serious abrasion and short service time.

Compared with bare tube economizer, H-finned tube economizer can enlarge the heat exchange area and reduce the number of tubes. It also can increase the flue gas flow area in order to reduce the flue gas flow speed and abrasion.

H-finned tube can be made as double H finned tubes , with high rigidness to fit long tube row.

The spiral finned economizer is a newly designed heat transfer equipment, consists of spiral fin tubes to overcome the serious abrasion and short service time.

Function

The function of the economizer is as its name implies, to “economize” or save on cooling costs. Obviously, it costs money to operate the compressor. If the compressor can be shut down and the system still provide adequate cooling, energy savings can be realized.

Product Paramenters

|

Description

|

Boiler economizer

|

|

Material

|

Alloy steel, Carbon steel, SA210C ,SA213T22, etc.

|

|

Material standard

|

ASTM, EN or ISO etc.

|

|

Dimension

|

Customization

|

|

Weight

|

Min: 10 ton

Max.:1000 ton |

|

Smelting Process:

|

EF+LF + VD

|

|

Process

|

Material→Ingot → Hot/Cold-Rolling→ Heat treatment (Normalizing+ tempering) → Inspection →rough machining→UT →2nd Heat treatment

→finishing machining →Inspection |

|

UT standard

|

ASTM A388 or EN10228, etc

|

Product packaging

For special cargos, such as overlength, overwidth, overheight and overweight cargos, we will choose frame boxes for easy handling.

For regular goods, we prefer ordinary containers

After loading the goods, we will reinforce them in all aspects

Hot Searches