- Product Details

- {{item.text}}

Quick Details

-

Hardness:

-

Full Hard

-

Skin Pass:

-

Yes

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Baosteel

-

Application:

-

Automotive Structure Hardware Machinery

-

Width:

-

700-2000MM

-

Length:

-

200-5000mm

-

Grade:

-

B400/780DP JSC780Y

-

Product Name:

-

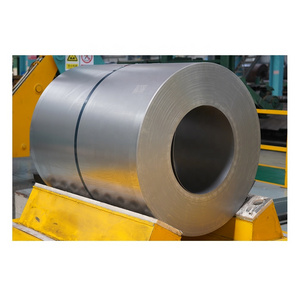

Cold Rolled Steel Plate Sheet

-

Special Use:

-

Automotive Steel

Quick Details

-

Type:

-

Steel Coil

-

Thickness:

-

0.3-3.5mm

-

Surface Treatment:

-

Normal Oiled

-

Hardness:

-

Full Hard

-

Skin Pass:

-

Yes

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Baosteel

-

Application:

-

Automotive Structure Hardware Machinery

-

Width:

-

700-2000MM

-

Length:

-

200-5000mm

-

Grade:

-

B400/780DP JSC780Y

-

Product Name:

-

Cold Rolled Steel Plate Sheet

-

Special Use:

-

Automotive Steel

B400/780DP high-strength steel cold-rolled automotive sheet. Brand interpretation

B: Baosteel, BAOSTEEL

400: Minimum yield strength specified, MPa

780: Minimum specified tensile strength, MPa

DP: Dual phase steel

Composition (Wt%)

C carbon element:<=0.18 Si silicon element:<=0.8 Mn manganese element:<=2.5 P phosphorus element:<=0.04 S sulfur element:<=0.015 Al aluminum element:>=0.005

Note 1: Alloy elements such as Nb, Ti, Cr, Mo, and B can be added as needed, with Nb+Ti+Cr+Mo+B ≤ 1.5%.

performance

Thickness:<=1

Thickness: 1-1.6

Thickness:>=1.6

Compared with ordinary high-strength steel cold-rolled products, DP series high-strength steel cold-rolled automotive sheet products have better composition control, more stable mechanical properties, and better formability.

DP series high-strength steel cold-rolled automotive sheet products have a lower yield to strength ratio, resulting in less rebound after cold forming, which can more accurately control the dimensional accuracy of the parts. Due to the use of advanced cooling technology in actual production, Baosteel's DP series high-strength steel for automotive panels is obtained through rapid cooling of low-carbon and low alloy components, which have good weldability and can be applied to various traditional welding methods.

Definition: Baosteel Group will provide a tensile strength of over 1000MPa (megapascals)

The ultra high strength steel used for automobile lightweighting is named Jipa steel ® (X-GPa) ®).

Baosteel has been committed to the research and production of high-end automotive panels, and in recent years

Combining the requirements of lightweight vehicle body and green environmental protection, vigorously developing Jeep steel ®

(X-GPa) ®) Product. Jipa steel ® Mainly used for car body frames,

It can significantly improve the active safety of automobiles while achieving lightweight and weight reduction

Effect. It is a green product implemented by Baosteel Group on the path of sustainable development

Exemplary. BaoQP ® Quenching and Partitioning Steel

QE Steel with High Hole Expansion

DP Dual Phase Steel

DH High Plasticity Dual Phase Steel

CP Composite Phase Steel

CH High Plasticity Composite Steel

MS Martensite Steel

TWIP Twining Induced Plasticity Steel

PHS hot forming steel/Press Hardening Steel, performance characteristics: QP steel uses martensite as the matrix phase and utilizes residual austenite

The TRIP effect of the body during deformation can achieve high machining hardness

Due to its chemical ability, it has higher plasticity and

Forming performance. Adopting Baosteel's innovative low point welding LME product design standards

And the manufacturing process makes QP steel galvanized products have low LME sensitivity

It effectively improves the spot welding performance of materials.

Main uses

Components. 980MPa grade QP steel is Baosteel's first global first product. order

Former BaoQP ® A large number of commercial applications have been achieved nationwide,

Mainly used for A-pillar reinforcement plate, B-pillar reinforcement plate, and door hinge reinforcement

Parts such as boards. Performance characteristics: With no yield extension, no room temperature aging, and low yield strength

The characteristics of high ratio, high work hardening index, and high baking hardening value.

Liang corrosion-resistant series products: using a high corrosion-resistant combination independently developed by Baosteel

Process can effectively remove surface alloying element enrichment and optimize the surface

Quality, improve the corrosion resistance of ordinary cold products, and enhance the electrophoretic coating performance

By doing so, we can obtain a high surface quality common cold DP product family.

High corrosion resistance, good coating, and advanced surface DP cold products can expand applications

Used for components in the vehicle body that require high corrosion resistance, such as:

Safety components such as door sills, seat crossbeams, door crash beams, A-pillars, B-pillars, etc

Application of structural components, especially in parts such as unpainted seat frames

The prospects are great.

Main use: DP steel series is currently the preferred steel for structural parts

Among them, products with low yield to strength ratios are mainly used for A-pillar reinforcement plates and B

Parts such as column reinforcement plates, with high yield to strength ratios, are mainly used in the transverse direction of the car bottom

Beam, threshold, door collision beam, seat frame, battery pack frame, etc

Item. Baosteel can comply with international standards such as European standards, American standards, or JIS standards

Supply can be carried out according to the required standards, or according to the user's standards or

Request for supply or use the following Baosteel standards

Supply.