- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

500 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

longsn

-

Year:

-

2020

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

by order

-

Hollow part volume:

-

500ml

-

Clamping Force (kN):

-

45

-

Power (kW):

-

35kw

-

Weight (KG):

-

3000 KG

-

Product name:

-

plastic bottle making equipment / blowing machine

-

Key words:

-

water bottles blowing machine

-

Capacity:

-

2000BPH

-

Bottle material:

-

Pet Plastic

-

Bottle type:

-

Plastic Round

-

Material:

-

Ss304/316

-

Advantages:

-

Easy Operation

-

Processing Type:

-

PET Bottle Making Blowing Machine

-

Cavity:

-

2-cavity

-

Feature:

-

High Stability

Quick Details

-

Neck Diameter(mm):

-

30 mm

-

Max.Bottle Diameter(mm):

-

80 mm

-

Max.Bottle Height(mm):

-

245 mm

-

Bottle Volume(ml):

-

500 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

longsn

-

Year:

-

2020

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

by order

-

Hollow part volume:

-

500ml

-

Clamping Force (kN):

-

45

-

Power (kW):

-

35kw

-

Weight (KG):

-

3000 KG

-

Product name:

-

plastic bottle making equipment / blowing machine

-

Key words:

-

water bottles blowing machine

-

Capacity:

-

2000BPH

-

Bottle material:

-

Pet Plastic

-

Bottle type:

-

Plastic Round

-

Material:

-

Ss304/316

-

Advantages:

-

Easy Operation

-

Processing Type:

-

PET Bottle Making Blowing Machine

-

Cavity:

-

2-cavity

-

Feature:

-

High Stability

Automatic pet bottle blow molding plant / plastic bottle making equipment / blowing machine

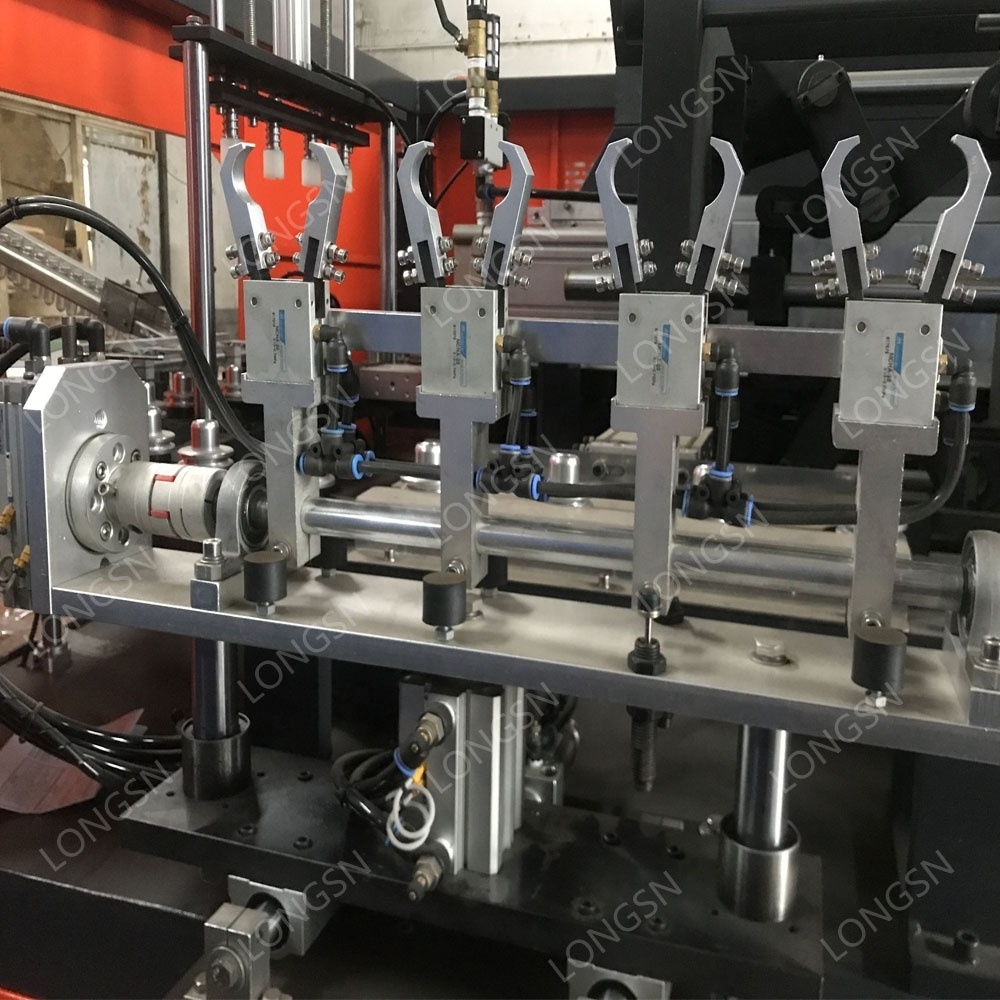

Machine Features:

1. High safety: No body injury hidden danger, machine avoids the danger of manual bottle taking, reduce the lost caused by accident, and increase productivity.

2.High speed and efficiency: adopts to high speed precision servo motor to control the pathway running.

3.Stable performance: adopts to SIEMENS man machine touch screen computer control system, which has the advantage of accurate, fast and stable. The structure is simple, heater and machine main part connected with slide way one body type, which is simple and easy to maintain.

4.Testing components use famous electrical equipment from Germany and Japan. Strong current control use

international famous brand, the performance stable and accurate.

5. Adopts to infrared tubes to heat the preforms. The tubes controlled in closed loop, which can well avoid the influence caused by outer voltage to the preform heating. The distance between tubes and performs can be easily adjusted, this is good for different bottle shapes and quality requirements.

6.wide mouth pet stretch blow molding machine has the function of automatic alarm and fault detect.

7.wide mouth pet stretch blow molding machine can keep 9 different data of 9 different blowing drafts. When change molds and performs, can straight use the data without redressing the data, very easy to operate.

8. Adpot to imported pneumatic components from Germany Japan Taiwan etc, can ensure running fast with zero fault rate.

9. wide mouth pet stretch blow molding machine

is high reaction, exchange fast, low fault rate, and running stable. The whole machine adopts to super

standard shockproof structure, which can reduce the shock to the lowest when machine in high speed running.

This prolong the use life of the components.

10. Air circuit has two parts, action and blowing, it can fulfill different air pressure requirements of blowing and action.

Can also buy high pressure blowing exhaust air recycle system, which will save air by 10-15%

11. Adopts to the new type double bend arm and four pull rod hydraulic clamping structure. High clamping force, and it will enlarge the pressure when blowing.

Machine Specification:

|

MODEL |

LFD-A2 |

|

|

OUTPUT |

Based on sample |

1800-2000PCS/H |

|

CONTAINER SPEC. |

Bottle body diameter |

20mm-80mm |

|

Body height |

50mm-245mm |

|

|

Neck size |

15mm-38mm |

|

|

MOLD |

Cavities |

2 cavities |

|

MACHINE POWER |

Power Voltage |

380v 50HZ |

|

Install power |

50kw |

|

|

Actual power |

30kw |

|

|

AIR SUPPLY |

Low air compressor |

1.0m3/min 1.0MPa |

|

High air compressor |

2.0m3/min 3.0MPa |

|

|

Air dryer |

2.0m3/min 3.0MPa |

|

|

COOLING WATER |

Cooling water capacity |

45L/min |

|

MAIN MACHINE DIM. |

L*W*H |

4000*2000*2100mm |

|

Weight |

3500kg |

|

|

PREFORM LOADER DIM. |

L*W*H |

1900*1100*2200mm |

|

Weight |

350kg |

|

|

SMC/ JAPAN |

|

|

Action valve |

SMC/ JAPAN |

|

Clamping Cylinder |

SMC/ JAPAN |

|

Stretch cylinder |

SMC/ JAPAN |

|

PLC |

Delta/TAIWAN |

|

Oily Water Separator |

|

|

Voltage regulator |

|

|

Switch |

OMRON/JAPAN |

|

Silicon control |

MITSUBISHI/JAPAN |

Automatic pet bottle blow molding plant / plastic bottle making equipment / blowing machine

Automatic pet bottle blow molding plant / plastic bottle making equipment / blowing machine

Before the order:

We will make detailed solution for you based on your requirments.

We will send you videos of our products to know more about our machines.

If you are willing to visit our factory,we will pick you up at a nearby airport/station.

After the order:

We will start to produce machines and update the progress.

Our engineer will draw the layout for you.

After-sales service:

Arrange our engineer to your factory to install machines if you need,train your employee until they can operate machines well.

Provide you 2 years warranty with spare parts 2 year free.

24 hours for engineer response (all services part 5days in customer hand by Intl' courier)

Automatic pet bottle blow molding plant / plastic bottle making equipment / blowing machine

Q1:Are you a trading company or a manufacturer ?

A1:We are the manufacturer ,we produce machines ourselves,we can assure the quality.

Q2:What is your advantage?

A2:Competitive price , Excellent technical support ,24h online service

Q3:When can I get my machines after I paid?

A3:We will arrange delivery on time,act according to the contract.

Q4:What's your guarantee or the warranty of the quality if we buy your machines?

A4:We offer you high quality machines with 2 years guarantee . we will give u spare part free in 2 years

Q5:How can I install my machine when it arrives?

A5:We will provide 24 hours online service,if needed we will send our engineer to your side as soon as you get all your machines ready,for testing and teaching your technicians how to run the machines.