Its innovative design facilitates seamless "online" measurements throughout production, ensuring swift and precise measurements. This feature contributes to the overall accuracy and efficiency of the cutting process.

- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Thickness:

-

1-20mm

-

Control Software:

-

FSCUT

-

Place of Origin:

-

Shandong, China (Mainland)

-

Brand Name:

-

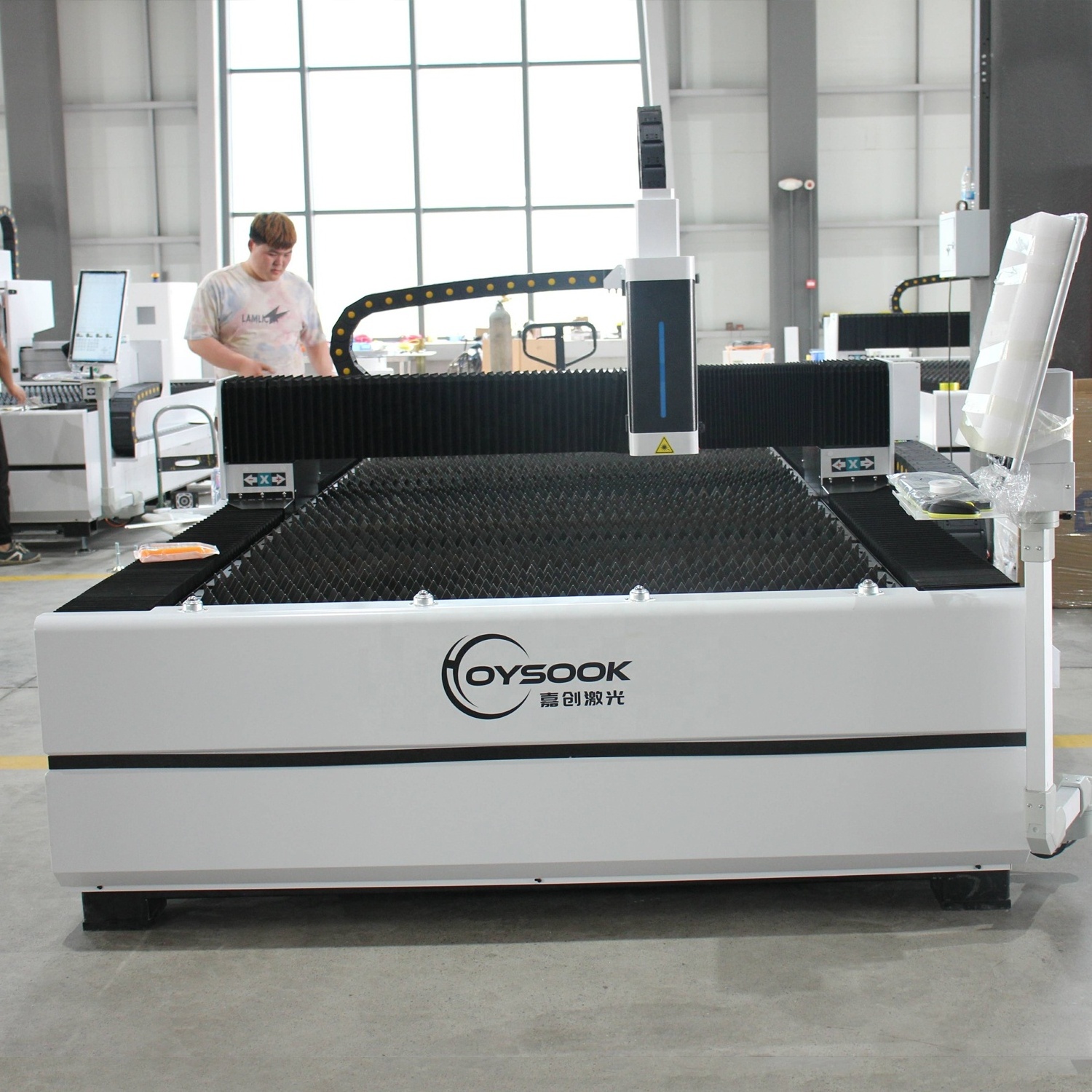

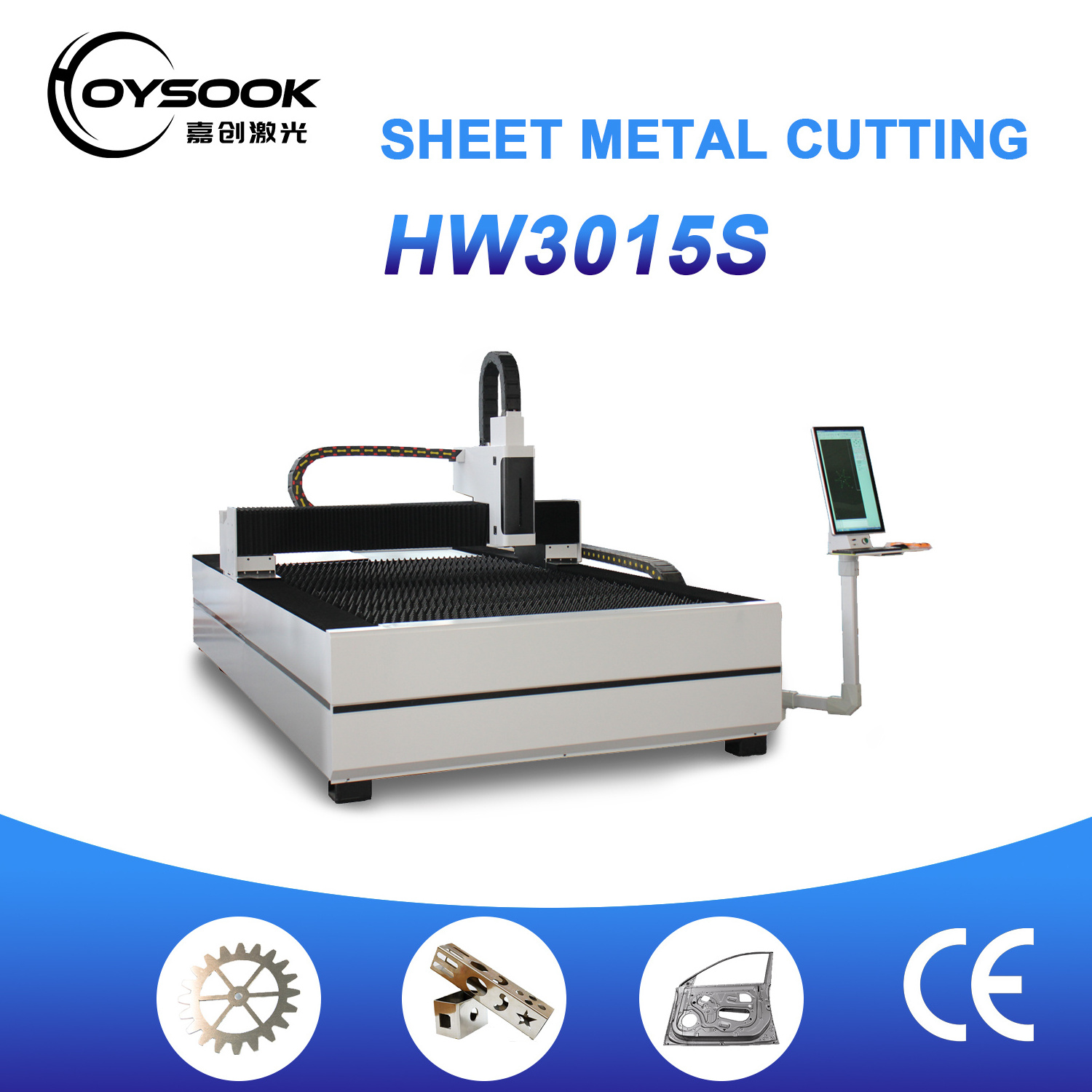

HOYSOOK

-

Weight (KG):

-

3500 KG

-

Laser power:

-

1000W 1500W /2000W /3000W /4000W /6000W

-

Key words:

-

laser cutting machines

-

Product name:

-

Fiber Laser Metal Cutting Machine

-

After-sales Service Provided:

-

Service Machinery Overseas

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

1-40000mm/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

Cutting Thickness:

-

1-20mm

-

Control Software:

-

FSCUT

-

Place of Origin:

-

Shandong, China (Mainland)

-

Brand Name:

-

HOYSOOK

-

Weight (KG):

-

3500 KG

-

Laser power:

-

1000W 1500W /2000W /3000W /4000W /6000W

-

Key words:

-

laser cutting machines

-

Product name:

-

Fiber Laser Metal Cutting Machine

-

After-sales Service Provided:

-

Service Machinery Overseas

Products Description

The HY serves as the perfect choice for those entering the world of planar laser cutting. With no need to worry about hefty purchase or training expenses, the HY makes laser cutting easily achievable.

Machine Features:

1. Experience top-tier laser performance combined with a reliable operating system, ensuring impeccable cutting results.

2. Witness the magic of automatic height adjustment, maintaining a consistent focal length and unwavering cutting quality.

3. The gantry structure and robust inblock aluminum cast cross beam join forces, providing exceptional rigidity, stability, and impact resistance.

4. Effortlessly load and unload plates during cutting, thanks to the convenient single countertop design, boosting processing efficiency.

5. Benefit from a spacious enclosed area, enhancing dedusting capabilities and preventing optical pollution.

6. Versatility shines as the HY confidently slices through various materials, delivering consistent, remarkable cutting outcomes.

7. Enjoy a flawless trio of cooling, lubrication, and dedusting systems, guaranteeing a steady, efficient, and long-lasting machine performance.

8.

The user-friendly control interface offers intuitive operation, allowing for precise adjustments and real-time monitoring of the cutting process, ensuring maximum convenience and accuracy

Specification

|

1

|

Machine Model

|

|

HY3015 , HY4015 , HY4020 , HY6020 , HY8025 , HY12025 , etc

|

|

||

|

2

|

Laser Power

|

|

1000w , 1500w , 2000w , 3000w , 4000w , 6000w , 8000w , 10000w , 12000w

|

|

||

|

3

|

Cut Thickness

|

|

0.5mm-30mm according to the power

|

|

||

|

4

|

Laser Generator

|

|

Raycus /MAX

|

|

||

|

5

|

Transmission system

|

|

Gear +rails

|

|

||

|

8

|

Max acceleration

|

|

1.0G

|

|

||

|

9

|

Voltage

|

|

380V /240V /120V

|

|

||

|

10

|

Laser wave length

|

|

1064nm

|

|

||

|

11

|

Machine color

|

|

Support custom made

|

|

||

Auto-focus laser head

Crafted from premium materials using cutting-edge technology, the auto-focus laser head exemplifies strength and durability.

Delta Servo Motor and Drive

1. Low Noise, Long Life:

Designed to run quietly and have a durable construction, ensuring reliable operation over an extended

lifespan. This reliability reduces maintenance needs and downtime.

2. Energy Efficiency: Optimized to use energy efficiently, helping to minimize power consumption and operational costs while

delivering high-performance output.

lifespan. This reliability reduces maintenance needs and downtime.

2. Energy Efficiency: Optimized to use energy efficiently, helping to minimize power consumption and operational costs while

delivering high-performance output.

3. Versatility:

Applied in a wide range of tasks beyond laser cutting, making them adaptable

for different industrial applications that require precise motion control.

for different industrial applications that require precise motion control.

The Cast Iron Bed

Utilizing a custom cast iron bed with flake graphite and a minimum tensile strength of 200 MPa ensures robustness and durability. This construction maintains machine tool accuracy over a remarkable 50-year span, delivering consistent and reliable performance over time.

Product Applications

The laser cutting

machines can be used for different materials, such as carbon steel, stainless steel, galvanized sheet, copper, aluminum, and so on.

And it has multiple uses.

Cut metal sheet

Engrave metal door

.

Drill hole on beam

Process accessories

Make metal signs

s.

Brass craft

Fiber Laser Cutting Equipment is suitable for metal cutting with Stainless Steel , Mild Steel Plate(tube), Carbon Steel, Alloy

Steel Plate, Spring Steel, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc

Different cutting thickness depends on different laser power selection in sheet metal laser cutting machine.

Steel Plate, Spring Steel, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc

Different cutting thickness depends on different laser power selection in sheet metal laser cutting machine.

Machine Characteristics

Machine Parts & Details

Packing & Delivery

1. Complete film wrap for the tube laser cutting machine.

2. Edge protection to prevent collisions during transportation.

3.Fumigation-free plywood wooden box and pallets securedwith iron binding belts for safe and reliable shipping.

2. Edge protection to prevent collisions during transportation.

3.Fumigation-free plywood wooden box and pallets securedwith iron binding belts for safe and reliable shipping.

Hot Searches