- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

890*920*900mm

-

Weight (T):

-

5 T

-

Power (kW):

-

15

-

size::

-

custom

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Lvyuan

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

890*920*900mm

-

Weight (T):

-

5 T

-

Power (kW):

-

15

-

size::

-

custom

Product Description

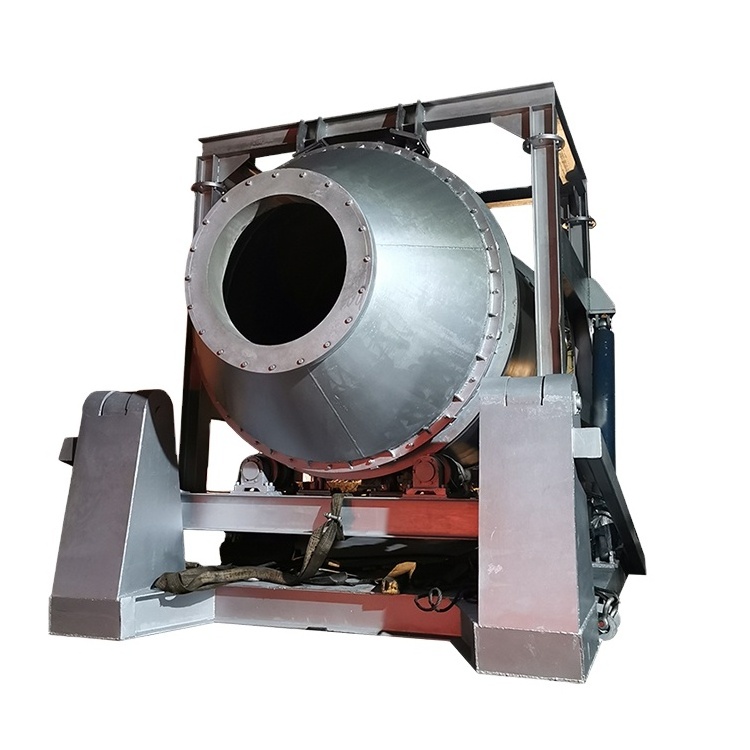

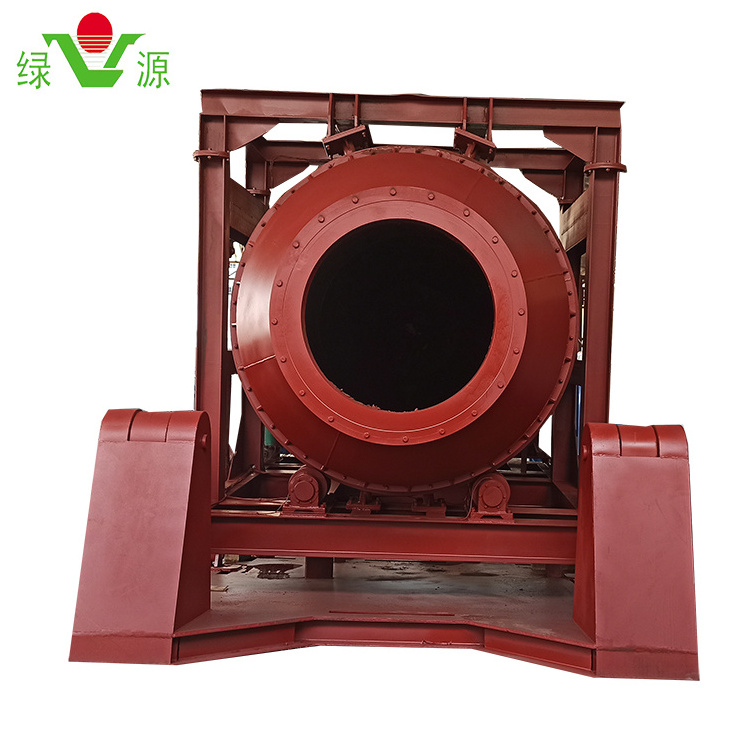

Specification

|

Mode

|

LY-5000

|

|

Motor Power

|

15KW

|

|

The rotary speed of stiming paddle

|

2r/min

|

|

Processing capacity

|

5000kg

|

Packing & Delivery

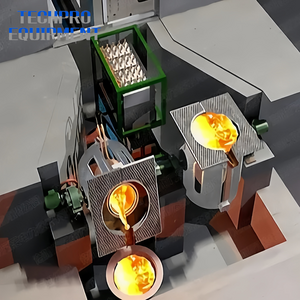

In the aluminum industry, scrap aluminum or alloy aluminum ingots are melted into molten aluminum in a smelting furnace, and a certain amount of aluminum slag is produced at the same time. Generally speaking, due to different materials (generally divided into electrolytic aluminum water, alloy aluminum ingot, There are several kinds of waste materials), the molten aluminum after melting in the furnace is roughly between 88%-98%, part of the molten aluminum and aluminum slag are raked out when raking the slag, and the aluminum slag raked out of the furnace The metal aluminum content is generally between 40-60%. Therefore, this part of the hot aluminum slag needs to be recycled to obtain good production benefits.

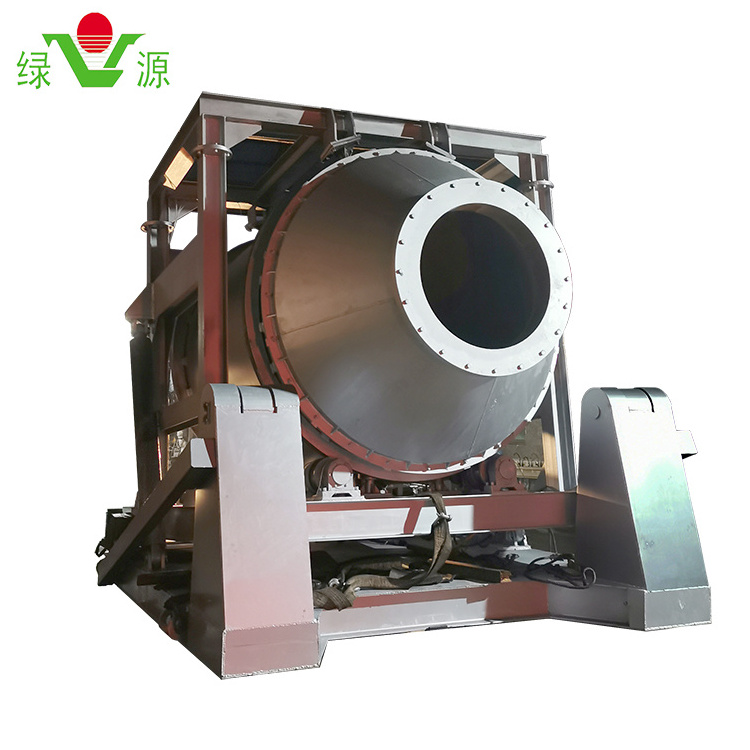

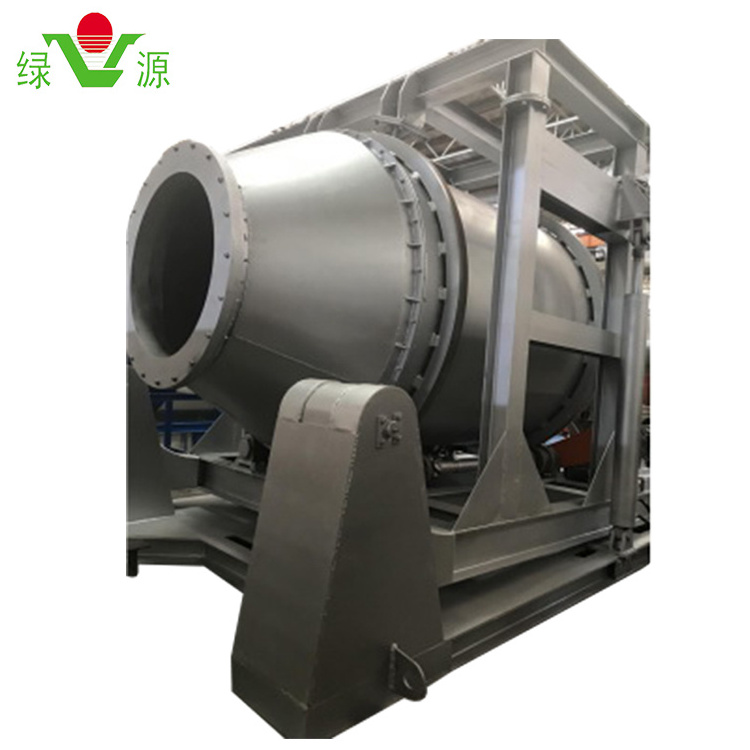

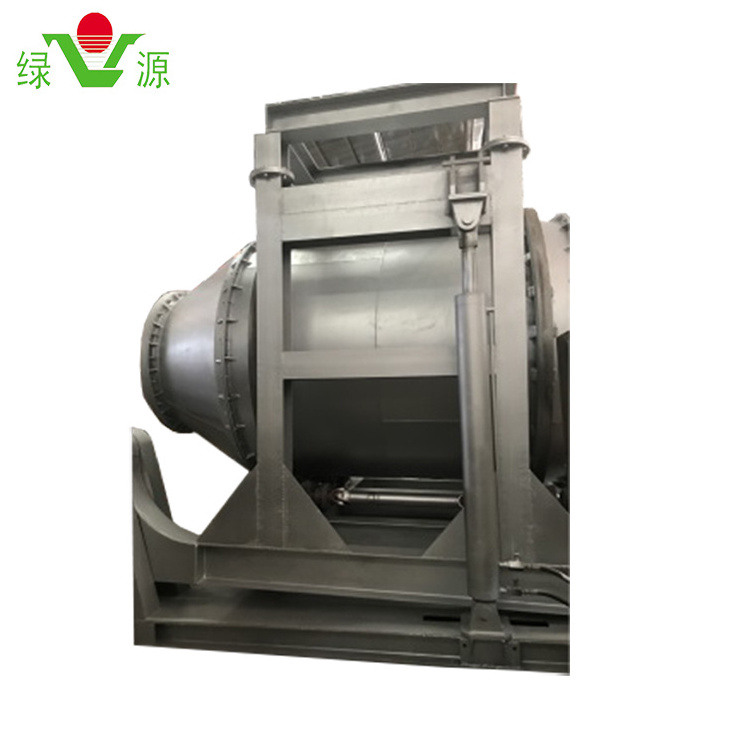

1. Judging from the current situation of use, the rotary furnace is an indispensable tool for aluminum ash treatment in the aluminum industry, and an important guarantee for the operating costs and profits of aluminum industry companies.

2. The function of the rotary kiln is to process the hot slag and other cold slags rake out of the furnace. Through the rotation of the barrel and the stirring of the forklift, the aluminum liquid and the aluminum slag are separated and precipitated to obtain a high-purity metal aluminum liquid.

3. The hot aluminum slag does not need to use an external heating source during the treatment process in the rotary furnace. It can use the combustibles in the aluminum slag to heat up, and does not need a slagging agent or a temperature increase agent, etc., which reduces the energy consumption and cost of processing the aluminum slag.

4. In order to prevent the temperature in the rotary furnace from being too high, causing deflagration and excessive burning of aluminum slag, the coarse ash selected from the cold ash bucket and some aluminum scraps and small raw aluminum can be added in the operation to prevent the slag splashing and control Temperature and increase the recovery rate. 5. The rotary kilns manufactured by our company are divided into 2 specifications and models of

5/8T according to the processing tonnage. Large batches of hot slag and cold slag can be processed, with high recovery rate, concentrated dust points, easy environmental protection, and control of dust generated during the production process, which not only reduces labor intensity, but also greatly improves the environmental pollution of slag processing。

Hot Searches