- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HKY

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

8.5*1.2*1.4M

-

Weight:

-

6.3T

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

screen:

-

color touch screen

-

control system:

-

PLC

-

guarantee:

-

18months

-

life time:

-

10 years

-

brand name:

-

HKY

-

color:

-

green

-

motor brand:

-

famous in China

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Certification:

-

BV

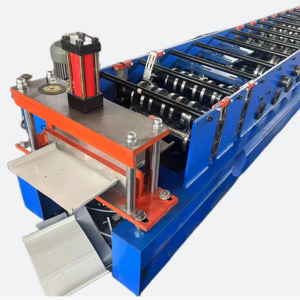

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

0-10m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HKY

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

8.5*1.2*1.4M

-

Weight:

-

6.3T

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

screen:

-

color touch screen

-

control system:

-

PLC

-

guarantee:

-

18months

-

life time:

-

10 years

-

brand name:

-

HKY

-

color:

-

green

-

motor brand:

-

famous in China

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Certification:

-

BV

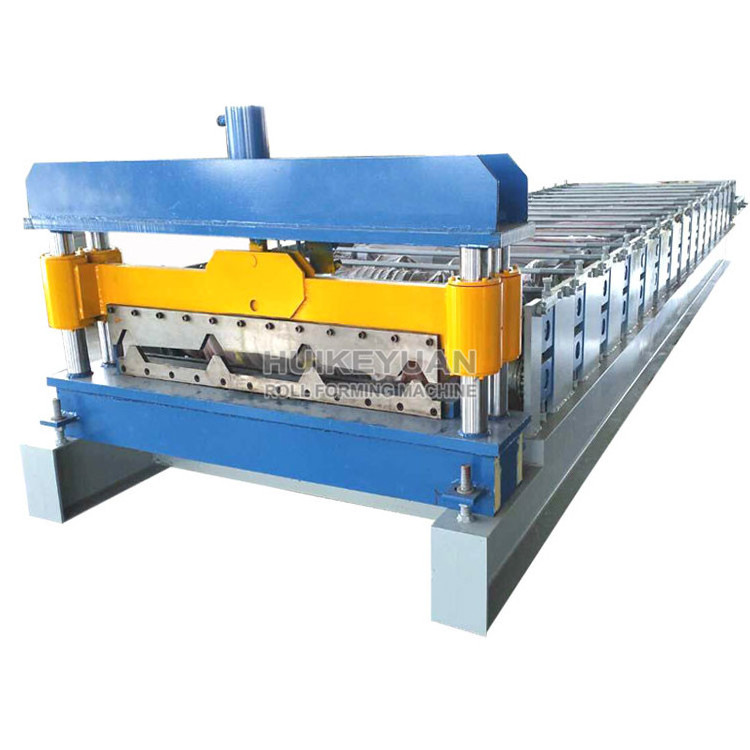

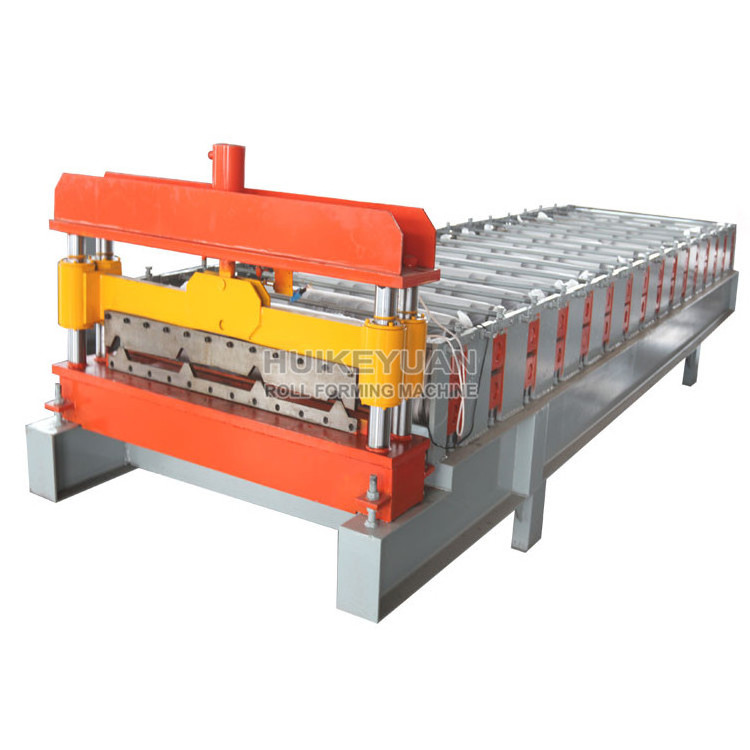

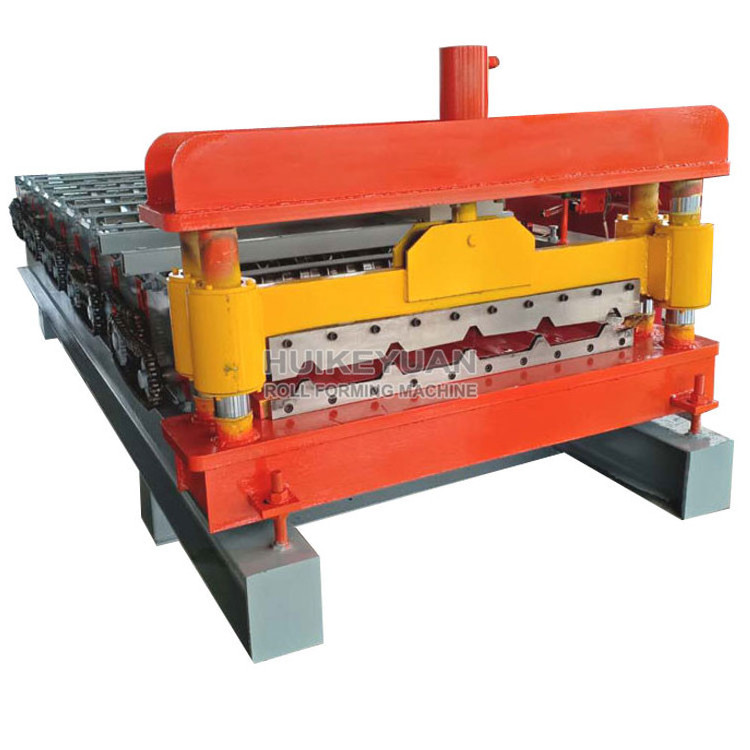

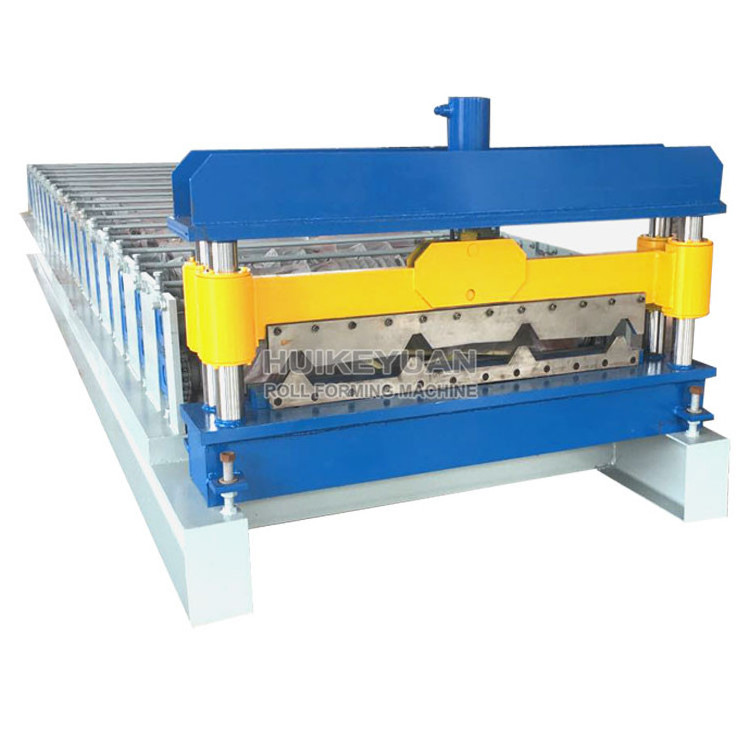

The roof & wall panel forming machine is rolled or cold-rolled strip steel, metal plate, galvanized plate, color steel as raw materials. Light metal profiles of different section shapes are obtained by bending at room temperature. Production of color steel products with different sections, production flexibility, easy to use, strong adaptability, save a lot of manpower and material resources, so the world's industrial developed countries are very seriously.

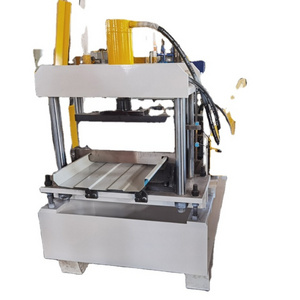

Guide four column type

The guide four column type high speed fine structure, pressure cylinder and die by the guide sleeve binding in 120 mm four solid oriented hydraulic prop, the mold under the vertical operation, will not produce the vertical deviation, especially on the tile die vulnerability, to absolute protection, but also greatly prolong the service life of the die

Rollers

High quality rollers will help to produce the beautiful and high quality profile. That will satisfy your customers.

Using high quality 95mm thick shaft, the strength is more durable.

Machine body

The main body of the body without welding, all the use of cast steel, the whole machine will not produce stress and lead to the host body deformation.

PLC Control System

Usually we prodvide the Delta PLC control system, but we can make that according to your need. You need which brand, then we send to you which brand.But the long life of that will bring you great benefit .

1. Shock bubble film

2. Suitable carton size

3. Shock bubble film

> Plastic Packing / Common Packing. Water-proof, Rust Prevention and Dust Prevention.

>By sea or other ways. In general, by sea, the port of loading is XINGANG PORT. It is only need 2 hours from our Company and Factory to Xingang Port, Tianjin City.

Our Factory

Our Exhibition Hall

Our Reception

Our Workshop

Q: How can I contact you?

A: Please look at my contact card. You can talk to me anytime. Or send me enquiry email, I will reply you in 24 hours and offer the optimum solution to you

Q: What is the status of After-sale Services for customers and machineries?

A: Engineers available to service machinery overseas. But the customers/buyer should pay for installation and commissioning fee 100$/day to our point account. We will provide the technical support for the whole life of the equipment and free training.

Q: How to visit our company?

A: 1.Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour),then we can pick up you.

2.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours),then we can pick up you.3.Fly to Guangzhou aiport: By air From Guangzhou to Beijing airtpot; By high speed train From Beijing Nan to Cangzhou Xi (1 hour),then we can pick up you.

Q: How many years since you have been in this field?

A: Our company has been producing roll forming machines for almost 20years.We have rich experience for manufacturing and designing the machine.

> Warranty: 2 Years.

During the warranty period, it covers all spare parts of machines, if you find some spare parts were damaged,

those new spare parts will be supplied free by us, but normal wear and tear excepted. And the freight should be bore equally by both parties.

> We could provide technical guiding, production, installation, debugging and maintenance service to all customers. After the end of the warranty period, it's not free.

> We will provide the technical support for the whole life of the equipment.

Contact me

Lisa Yang (Sales Manager)

BOTOU HUIKEYUAN ENGINEERING CONTROL CO.,LTD.

Add: Fuzhuang Development Zone Botou City, Hebei, China

http://www.hkyformingmachine.com

Skype: lisayang213

Fax: +86-317-3087243

Cel: +86-15612755608/18660770108

we warmly weclome you to visit our facory!