Surface treatment

We can also do special treatment on the aluminum roller surface which can realize good scratch resistance, abrasion resistance and

anti-sticking performance.

01. Anodizing treatment HV300,the surface is silver.

02. Hard anodic oxidation treatment HV700,the surface is dark brown.

0.3 Green hard treatment,the surface is green.The roller is Anti-adhesion, anti-corrosion.

04. Mirror hard anodic oxidation treatment HV700 treatment, the surface is dark brown and has excellent mirror gloss.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

zle022

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

zhele

-

Product name:

-

High Performance Pipe Conveyor Idler Roller and Trough Roller

-

Application:

-

Industrial Equipment

-

Equipment:

-

CNC Machining Centres

-

Process:

-

Forging+machining+heating Treatment

-

Surface Treatment:

-

Chrome Plating

-

Material Capabilities:

-

Hardened Metals

-

Color:

-

Customized Color

-

Certification:

-

ISO9001

-

Quality:

-

High Precision

-

Diameter:

-

0.3-17mm

Quick Details

-

Weight (KG):

-

20

-

Material:

-

aluminum, 100% Steel

-

Torque Capacity:

-

customized

-

Model Number:

-

zle022

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

zhele

-

Product name:

-

High Performance Pipe Conveyor Idler Roller and Trough Roller

-

Application:

-

Industrial Equipment

-

Equipment:

-

CNC Machining Centres

-

Process:

-

Forging+machining+heating Treatment

-

Surface Treatment:

-

Chrome Plating

-

Material Capabilities:

-

Hardened Metals

-

Color:

-

Customized Color

-

Certification:

-

ISO9001

-

Quality:

-

High Precision

-

Diameter:

-

0.3-17mm

Product Description

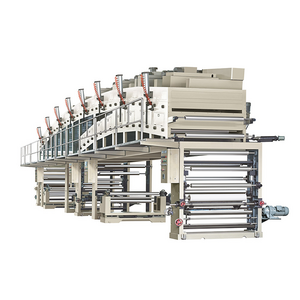

China Make Direct Factory Aluminum Alloy Guide Roller Professional Printing Roller

Cheap wholesale aluminum self cleaning screw roller

We adopt high quality aluminum alloy as the body material,use extrusion molding and make ribs structure inside.The outside diameter can be made from 25mm to 320mm. Under the treatment by computer balancing correction process,the dynamic balance of the

aluminum roller will be smaller than 2g.With using of sophisticated equipment and special tools,the roll surface gloss can be 0.8, concentricity can reach 0.02mm.

Special treatment in the shaft axle and the using of imported bearings will make sure the the aluminum guide roller work very well at high speed with no deformation.

2.Advantages Of ZHELE Aluminum Guide Rollers:

*Good material

The aluminum material is well selected, has good chemical properties, is not easy to age, and has a long service life.

*Delicate and smooth

The overall surface is smooth, polished processing, can improve work efficiency.

*Multiple choices

Variety of styles, fair prices, complete specifications.

|

Body material

|

Aluminum

|

|

Diameter

|

22-320mm

|

|

Length

|

100-6000mm

|

|

Weight

|

1-100kg

|

|

Anodize

|

HV300/HV700

|

|

Thickness of anodize

|

20-80μm

|

|

Type

|

Without shaft/ With shaft/ Through shaft

|

|

Surface

|

Smooth/ Cross line/ Center line/ Groove line

|

|

Smoothness

|

Ra6.3-0.4

|

|

Balancing

|

G6.3/G2.5

|

Features and applications

Our aluminum guide rollers have the characteristics of high strength, low resistance, light weight, flexible rotation, no-rusty, wear resistance and corrosion resistance.

* Printing systems: conveyors and in-feeders

*Wood-working systems: saws, wood-working machine, laminators

* Office equipment: electronic copy machines, calculators, fax machines, coin counters, printers

* Testing systems: lab machines, durability testers, measuring systems

* Food processing systems: meat cutting machines, cookie making machines, canning machines, noodle making machines

* Others: speed reducers, electroplating machinery, physics and chemistry machines, paper-making machines, pulp processing

machines.

Our aluminum guide rollers have the characteristics of high strength, low resistance, light weight, flexible rotation, no-rusty, wear resistance and corrosion resistance.

* Printing systems: conveyors and in-feeders

*Wood-working systems: saws, wood-working machine, laminators

* Office equipment: electronic copy machines, calculators, fax machines, coin counters, printers

* Testing systems: lab machines, durability testers, measuring systems

* Food processing systems: meat cutting machines, cookie making machines, canning machines, noodle making machines

* Others: speed reducers, electroplating machinery, physics and chemistry machines, paper-making machines, pulp processing

machines.

Detailed Images

1. Base roller

A. Material: 45# steel tube or No.5 series aluminum

General performance requirement:45# steel tube

Lighter weight requirement : No 5 series aluminum

B.Thickness : 15mm-25mm

We can also make the special thickness according to customers requirement.

C. A strict inspection procedure of base roller:

Incoming inspection including surface roughness,straightness, dynamic balance,cylindricity and so on.

2. Chrome oxide ceramic layer

A. Using the famous plasma spraying machine from Switzerland supplier.

B. The evenness of 80% ceramic powder can be controlled between 15u-35u

C. The hardness of chrome oxide ceramics can reach 1200HV.

3. Antiseptic treatment

we use the nanoscopic sealant to coat on the surface of the ceramic which can reach the tiny cell to protect the base roller from solvent corrosion.

4. Precise delivery on the inks

First,we make trial engraving before the real engraving.

Second,we use the scanner to scan each layer to test the volume of the cell.

Third,according to the relationship between the LPI and BCM , we can make sure whether the LPI is workable.

5. Quality Control

We have the quality control system during the whole production from the very beginning to the end to make sure each roller is qualified. And we will issue the certification for our customers after the products are finished.

6. Service life

Under normal operation and maintenance,our ceramic anilox rollers can work 8-10 years or even longer.

A. Material: 45# steel tube or No.5 series aluminum

General performance requirement:45# steel tube

Lighter weight requirement : No 5 series aluminum

B.Thickness : 15mm-25mm

We can also make the special thickness according to customers requirement.

C. A strict inspection procedure of base roller:

Incoming inspection including surface roughness,straightness, dynamic balance,cylindricity and so on.

2. Chrome oxide ceramic layer

A. Using the famous plasma spraying machine from Switzerland supplier.

B. The evenness of 80% ceramic powder can be controlled between 15u-35u

C. The hardness of chrome oxide ceramics can reach 1200HV.

3. Antiseptic treatment

we use the nanoscopic sealant to coat on the surface of the ceramic which can reach the tiny cell to protect the base roller from solvent corrosion.

4. Precise delivery on the inks

First,we make trial engraving before the real engraving.

Second,we use the scanner to scan each layer to test the volume of the cell.

Third,according to the relationship between the LPI and BCM , we can make sure whether the LPI is workable.

5. Quality Control

We have the quality control system during the whole production from the very beginning to the end to make sure each roller is qualified. And we will issue the certification for our customers after the products are finished.

6. Service life

Under normal operation and maintenance,our ceramic anilox rollers can work 8-10 years or even longer.

Size Information

Size Chart of This Design

|

External dia. ΦD

|

Internal dia. ΦD1

|

Processing length L

|

Unilateral thickness H

|

Ribs R

|

Dia. of sahft hole ΦD2

|

|

Φ30mm

|

Φ23.5mm

|

200~1200mm

|

3.25mm

|

-

|

The dia.& depth of the shaft hole can be customized

|

|

Φ40mm

|

Φ31mm

|

200~1200mm

|

4.50mm

|

-

|

|

|

Φ50mm

|

Φ42mm

|

250~1500mm

|

4.00mm

|

R4.1mm*8(6)

|

|

|

Φ60mm

|

Φ52mm

|

300~1800mm

|

4.00mm

|

R4.1mm*8(6)

|

|

|

Φ70mm

|

Φ61mm

|

300~1800mm

|

4.50mm

|

R4.1mm*8(6)

|

|

|

Φ75mm

|

Φ61mm

|

300~1800mm

|

7.00mm

|

R4.1mm*8(6)

|

|

|

Φ80mm

|

Φ71mm

|

300~1800mm

|

4.50mm

|

R4.1mm*8

|

|

|

Φ90mm

|

Φ81mm

|

300~2000mm

|

4.50mm

|

R4.1mm*8

|

|

|

Φ100mm

|

Φ91mm

|

300~2500mm

|

4.50mm

|

R4.5mm*8

|

|

|

Φ120mm

|

Φ110mm

|

300~2500mm

|

5.00mm

|

R4.5mm*8

|

|

|

Φ150mm

|

Φ137mm

|

400~3500mm

|

6.50mm

|

R5.0mm*9

|

|

|

Φ160mm

|

Φ145mm

|

400`3500mm

|

7.50mm

|

R5.0mm*9

|

|

|

Φ170mm

|

Φ155mm

|

450~3500mm

|

7.50mm

|

R5.0mm*9

|

|

|

Φ180mm

|

Φ165mm

|

450~3500mm

|

7.5mm

|

R5.0mm*9

|

|

|

Φ200mm

|

Φ185mm

|

450~3500mm

|

7.50mm

|

R8.0mm*10

|

|

|

Φ220m

|

Φ205mm

|

450~3500mm

|

7.50mm

|

R8.0mm*10

|

|

Related Products

Packing&Shipping

Packaging and ShippingWe regard packaging as a crucial link. Careful and appropriate packaging is fairly important to ensure the good condition and successful delivery of the belt conveyor idler rollers.

The following represents the most common practice:

· Wrap each roller with plastic film

· It is evacuated between the roller and the plastic film.

· Add desiccant.

· Bubble wrap.

· Plywood case

The following represents the most common practice:

· Wrap each roller with plastic film

· It is evacuated between the roller and the plastic film.

· Add desiccant.

· Bubble wrap.

· Plywood case

After Sales Service

Company Introduction

Based on over 10 years experience in air shaft lines, ANHUI ZHELE MECHANICAL AND ELECTRICAL CO.,LTD was founded in 2006, is a production, design integration of the enterprise.

Using Taiwan professional production technology and advanced production equipment, professional production of face mask,face mask machine,Air expanding shaft(key type),Air expanding shaft(friction),Air expanding shaft(leaf type),shaft parts,aluminum roller

with rotation shaft,aluminum roller with rotation shaft,aluminum roller without shaft,aluminum roller with stripe,safey chucks(flange type),safety chuk(slip type),safety chuk(pedeatal type),Electromagnetic Clutch,Air cluth,Air brake,Tension detector,EPC Edge Position Control,CPC Center position control,Tension detector,Automatic tension controller,Manual tension controller,Semi-Auto tension controller,Powder,Powder cluth,Powder brake,Electromagnetic clutch,Electromagnetic brake,etc.

Miraculously zhele Electromechanical, leading a few microns fine circles.

Using Taiwan professional production technology and advanced production equipment, professional production of face mask,face mask machine,Air expanding shaft(key type),Air expanding shaft(friction),Air expanding shaft(leaf type),shaft parts,aluminum roller

with rotation shaft,aluminum roller with rotation shaft,aluminum roller without shaft,aluminum roller with stripe,safey chucks(flange type),safety chuk(slip type),safety chuk(pedeatal type),Electromagnetic Clutch,Air cluth,Air brake,Tension detector,EPC Edge Position Control,CPC Center position control,Tension detector,Automatic tension controller,Manual tension controller,Semi-Auto tension controller,Powder,Powder cluth,Powder brake,Electromagnetic clutch,Electromagnetic brake,etc.

Miraculously zhele Electromechanical, leading a few microns fine circles.

Our Services & Strength

Eight reasons to choose us:

1. Perfect service system and after-sale protection.

2. Quality problems will be solved within 24 hours.

3. One-to-one customer service tracking processing.

4. Companies carry out the ERP management, improve enterprise fast response.

5. Quality assurance, one year warranty.

6. Supporting professional matched other equipment.

7. The company has more than one product testing units, the implementation of ISO9001: 2015.

8. Unique development and design capabilities to meet the needs of special-purpose equipment manufacturing.

Five Core strengths:

1. The first domestic independent R & D manufacturer and 10 years of professional manufacturing.

2. Casting exquisite, beautiful, practical and durable.

3. Complete specifications, cost-effective and spot supply.

4. Independent research and development, special specifications can be customized.

5. Selected materials, high-tech treatment, up to the international standard test.

FAQ

1.When can I get the quotation?

We usually quoted within 24 hours after receiving your inquiry. If you are very urgent to get the price, please call us or tell your email, so that we can regard your inquiry priority.

2.How should I place an order?

Please let us know the model number based on our specs for powder clutch, powder brake, air clutch, air brake, electromagnetic clutch, electromagnetic brake and safety chucks, other transmission parts.

For air shafts,air adapter please show us your drawing, or let us know your request, and then we will provide you drawing for confirmation.

3.What’s your MOQ basis?

Normally, we don’t have MOQ request, except the customized mini clutches/brakes.

4.What about the lead time for production?

Honestly, it depends on the order quantity and the type of our products. For powder clutch, powder brake, tension controller,which is about 3-5 days. For safety chucks, air shafts which need about 15-30 days.

5.What is the term of shipment?

We can arrange with EXW, FOB, CIF…etc. You can choose the most convenient one or cost-effective way.

More concerned for our products , please do not hesitate to inquiry now!

We usually quoted within 24 hours after receiving your inquiry. If you are very urgent to get the price, please call us or tell your email, so that we can regard your inquiry priority.

2.How should I place an order?

Please let us know the model number based on our specs for powder clutch, powder brake, air clutch, air brake, electromagnetic clutch, electromagnetic brake and safety chucks, other transmission parts.

For air shafts,air adapter please show us your drawing, or let us know your request, and then we will provide you drawing for confirmation.

3.What’s your MOQ basis?

Normally, we don’t have MOQ request, except the customized mini clutches/brakes.

4.What about the lead time for production?

Honestly, it depends on the order quantity and the type of our products. For powder clutch, powder brake, tension controller,which is about 3-5 days. For safety chucks, air shafts which need about 15-30 days.

5.What is the term of shipment?

We can arrange with EXW, FOB, CIF…etc. You can choose the most convenient one or cost-effective way.

More concerned for our products , please do not hesitate to inquiry now!

Hot Searches