- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v or customized

-

Dimension(L*W*H):

-

depends

-

Weight:

-

100 KG

-

Product name:

-

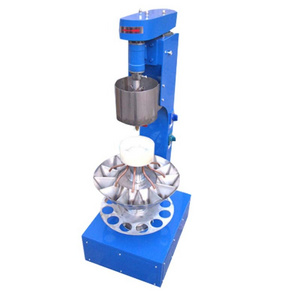

XFLB Closed Circuit Continuous Flotation Machine

-

Color:

-

Customized Making

-

Quality:

-

High Reputation

-

Installation:

-

Under Guidance

-

Function:

-

Screening\separation\sorting\sieving

-

Price:

-

Negotiable

-

Certification:

-

ISO CE

-

Recovery rate:

-

98%~99%

-

Feature:

-

Easy Maintenance\High Effecient

-

After-sales Service Provided:

-

Provided

Quick Details

-

Production Capacity:

-

1-5tph

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Walker

-

Voltage:

-

380v or customized

-

Dimension(L*W*H):

-

depends

-

Weight:

-

100 KG

-

Product name:

-

XFLB Closed Circuit Continuous Flotation Machine

-

Color:

-

Customized Making

-

Quality:

-

High Reputation

-

Installation:

-

Under Guidance

-

Function:

-

Screening\separation\sorting\sieving

-

Price:

-

Negotiable

-

Certification:

-

ISO CE

-

Recovery rate:

-

98%~99%

-

Feature:

-

Easy Maintenance\High Effecient

-

After-sales Service Provided:

-

Provided

Product Description

DELUXE FLOTATION PILOT PLANT

This flotation pilot plant is a complete, but still small miniature froth flotation plant is ideal for in-house pilot plant testing your mining project. Its layout is for a mono-metallic flowsheet (buy section for each additional metal). Its flotation cell agitators tip speed can be varied between 3 set-points. The froth paddles or scrapers also offer 2 rotation settings. As presented, this small laboratory float plant weighs 160 kilo and offers:

1. A 20 Litre flotation feed conditioner tank to store your grinding mill product.

2. An 8 cell rougher/scavenger flotation bank of 1 Litre each cell.

3. A 5 Liter conditioner & mixing tank.

4. A 4 cell first stage cleaning of 0.75 Litre each cell.

5. A 5 Liter conditioning vessel.

6. A 2 cell second cleaner bank of 0.5 Litre each cell.

Micro-dosage reagent pumps and hose pumps for concentrate/slurry stream.1-year-warranty

Assuming a 35% flotation density and a 2.8 SG to your test ore feeding this laboratory flotation pilot plant, you will have approximately 25 minutes of conditioning time with 15 minutes of rougher flotation time if operated at 13 kilos/hour (200 grams/minute).

To address the limitations of the band scale test, and the high cost of the conventional pilot plant, We has developed an innovative solution, called the Mini Flotation Pilot Plant. The Mini Flotation Pilot Plant or MFPP produces the same type of engineering data as the conventional plant, but at a fraction of the operating costs, since the MFPP requires a relatively small amount of sample ore and minimal personnel to operate.

The Mini Flotation Pilot Plant permits flotation testing with continuous flows, similar to traditional pilot plants. But is designed to make use from samples obtained from exploration drilling campaigns. Modular in design, the heart of the MFPP is comprised of: the flotation module, the continuous regrind pin mill, the column flotation module and the reagent dispensing system which can have up to 16 precision chemical dosing pumps. The flotation module consists of 12 flotation cells, modelled after the standard Denver D12 laboratory cell and uses the same impeller and tank design. As well, each cell has individual level control. The products of each cell are moved to the next using peristaltic pumps.

Auxiliary components include the batch grinding mill; ergonomically designed to reduce material handling and turnaround time for grinding large samples, with a nominal capacity of up to 20kg per batch. The slurry holding tank, the Mini Flotation Pilot Plant feed tank and optional computer system for data logging and control. The scale of equipment handles feed ranges from 5-15 kilograms per hour. A high level of instrumentation is also included to permit digital logging of pilot plant data and replication of conditions from test to test.

Instrumentation includes:

variable speed froth paddles, impeller speed measurement and variable speed slurry transfer pumps.

Does not include:

precision reagent addition

With the Mini Flotation Pilot Plant, the ore can be subjected through the following treatment stages: grinding, rougher and scavenger flotation, regrinding of concentrate tailing streams, cleaning of reground product, scavenging of cleaner tailings, recleaning of the concentrate. Furthermore, the flexibility in arranging circuits in the MFPP means that various flow sheets can be tested. The merit of testing using either conventional Pilot Plant or Mini FlotationPilot Plant is that both these methods can test the process on a continuous basis, which is of major importance to the investor. When the two are compared, we start to see the differences. The MFPP allows for greater operational flexibility, allowing optimization for working conditions during execution.

Specification

|

PF842

|

|

Unit

|

Continuous Flotation Machine

|

|

|

slurry Storage Dam

|

Mixing Tank

|

|||||

|

|

|

|

1

|

0.75

|

0.5

|

|

|

|||||

|

|

|

|

8 cells

|

4 cells

|

2 cells

|

|

|

|||||

|

Cell Volume

|

|

L

|

1

|

0.75

|

0.5

|

20

|

5

|

|||||

|

lmpeller Diameter

|

|

mm

|

|

|

|

|

|

|||||

|

lmpeller Speed

|

1

|

m/s

|

7.9

|

7.5

|

7.5

|

7.5

|

7.4

|

|||||

|

|

2

|

|

7

|

6.9

|

6.9

|

6.1

|

6.5

|

|||||

|

|

3

|

|

6

|

6

|

6

|

|

5.8

|

|||||

|

Froth Paddle Speed

|

1

|

RPM

|

20

|

|

|

|

|

|||||

|

|

2

|

|

30

|

|

|

|

|

|||||

|

Feeding Size

|

|

um

|

under 300 microns

|

|

|

|

|

|||||

|

The Main Motor Power

|

|

Watts

|

180/2cell

|

|

|

180

|

90

|

|||||

|

Capacity

|

|

kg/h

|

2 to 13

|

|

|

|

|

|||||

|

Weight

|

|

kg

|

160

|

|

|

|

|

|||||

Packing&Delivery

◆ Ways of packing

1.Small parts packed in the wooden cases

2.Big parts packed by plastic membrane

3.The whole big machine is loaded in the container

3.The whole big machine is loaded in the container

◆ Shiping by sea/air freight

or any way the customer requires

Hot Searches