Mixer

Power:3kw

Output:70-100kg/h

Size:900*700*1200mm

Function:

To mix the material such as the wheat flour and waster.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/50HZ

-

Power:

-

154kw

-

Dimension(L*W*H):

-

23000*1500*1800mm

-

Weight:

-

3 KG

-

Warranty:

-

1year

-

Marketing Type:

-

New Product 2021

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Steam pressure:

-

1.5kg/cm2

-

Acting width:

-

210mm

-

Output:

-

111000pcs/8h

-

Name:

-

Cereal Grain Corn Noodle Making Machine

-

power:

-

154kw

-

Function:

-

to mix the material such as the wheat flour and waster

-

Title:

-

Automatic noodle making machine

-

Packing:

-

Wooden Box

-

Material:

-

Stainless Steel

-

Certification:

-

CE,ISO

Quick Details

-

Production Capacity:

-

180 kg/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

MT

-

Voltage:

-

380V/50HZ

-

Power:

-

154kw

-

Dimension(L*W*H):

-

23000*1500*1800mm

-

Weight:

-

3 KG

-

Warranty:

-

1year

-

Marketing Type:

-

New Product 2021

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Steam pressure:

-

1.5kg/cm2

-

Acting width:

-

210mm

-

Output:

-

111000pcs/8h

-

Name:

-

Cereal Grain Corn Noodle Making Machine

-

power:

-

154kw

-

Function:

-

to mix the material such as the wheat flour and waster

-

Title:

-

Automatic noodle making machine

-

Packing:

-

Wooden Box

-

Material:

-

Stainless Steel

-

Certification:

-

CE,ISO

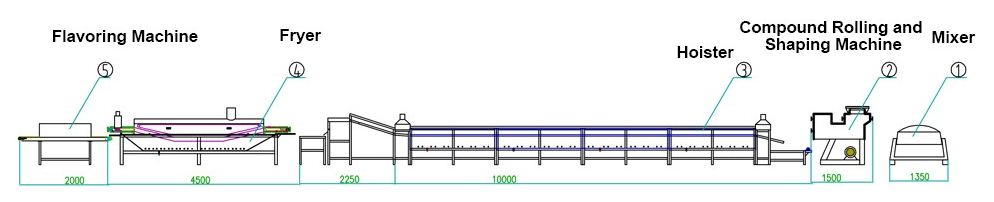

Industrial Instant Noodle Production Line /Cereal Grain Corn Noodle Making Machine

Product Description

Industrial Instant Noodle Production Line /Cereal Grain Corn Noodle Making Machine

,with perfect technology,compact structure,original design and stable performance,is developed on the base of like produces and requirements in the world market,it realizes high automation ,convenient operation,low energy and small floor space ,that assures all working procedures from feeding flour to finished products can be accomplished once.

The investment for this line is only one tenth of that large size equipment,especially suitable to small-size or self-owned enterprises,the corrugated instant noodle produced by this line tenacious,smooth and transparent,it is very easy to be saturated by water.

The investment for this line is only one tenth of that large size equipment,especially suitable to small-size or self-owned enterprises,the corrugated instant noodle produced by this line tenacious,smooth and transparent,it is very easy to be saturated by water.

Specification

|

Model

|

XBF-III Electrical instant noodles line

|

XBF-III Steam instant noodles line

|

|

Installed capacity

|

154kw

|

4.2kw

|

|

Steam pressure

|

1.5kg/cm²

|

6kg/cm²

|

|

Acting width

|

210mm

|

210mm

|

|

Output

|

111000pcs/8h

|

11000pcs/8h

|

|

Size

|

26000*700*1500mm

|

26000*700*1500mm

|

Details Images

Mixer- Roller pressing machine- Boiling machine-Fryer-Cooling machine

Roller pressing machine

Power:4kw

Output:70-100kg/h

Size:2300*700*1450mm

Function:

To make noodle-shaping

Power:4kw

Output:70-100kg/h

Size:2300*700*1450mm

Function:

To make noodle-shaping

Boiling machine

Power:126kw

Output:

70-100kg/h

Size:14000*700*1900mm

Function:

To boil the noodle

Power:126kw

Output:

70-100kg/h

Size:14000*700*1900mm

Function:

To boil the noodle

Fryer

Power;64kw

Output:70-100kg/h

Size:6000*870*26000mm

Function:

To fry the instant noodle

Power;64kw

Output:70-100kg/h

Size:6000*870*26000mm

Function:

To fry the instant noodle

Cooling machine

Power:0.77kw

Output:70-100kg/h

Size: 6000*700*800mm

Function:

Have a cool the noodle

Power:0.77kw

Output:70-100kg/h

Size: 6000*700*800mm

Function:

Have a cool the noodle

Main Features

*The line produces corrugated instant noodles with short rehydration time, good elasticity, smoothness and transparency, which can be compared with the popular large-scale equipment in the market.

*The company is responsible for the installation, debugging equipment, training personnel until the production of qualified products;Provide process formula, provide seasoning, agent printed packaging bags.

Packing & Delivery

♥Wooden or metal case according to specific size of each equipment, we twine thick plastic coating for each machine.

♥Tight the equipment in the truck without space to ensure no rubbing during the transportation.

♥Tight the equipment in the truck without space to ensure no rubbing during the transportation.

Services & Customer

1. Pre-sale services:

Act as a good adviser and assistant of clients, enable them to get rich and generous returns on their investments.

a. Select equipment model;

b. Design and manufacture products according to clients' special requirement;

c. Train technical personnel for clients.

2. Services during the sale:

Respect clients, devote ourselves to improving the total value of clients.

a. Pre-check and accept products ahead of delivery;

b. Help clients to draft solving plans.

3. After-sale services:

Provide considerate services to minimize clients' worries.

a. Assist clients to prepare for the first construction scheme;

b. Install and debug the equipment;

c. Train the first-line operators;

d. Examine the equipment;

e. Take initiative to eliminate the troubles rapidly;

f. Provide perfect service;

g. Provide technical exchanging.

Act as a good adviser and assistant of clients, enable them to get rich and generous returns on their investments.

a. Select equipment model;

b. Design and manufacture products according to clients' special requirement;

c. Train technical personnel for clients.

2. Services during the sale:

Respect clients, devote ourselves to improving the total value of clients.

a. Pre-check and accept products ahead of delivery;

b. Help clients to draft solving plans.

3. After-sale services:

Provide considerate services to minimize clients' worries.

a. Assist clients to prepare for the first construction scheme;

b. Install and debug the equipment;

c. Train the first-line operators;

d. Examine the equipment;

e. Take initiative to eliminate the troubles rapidly;

f. Provide perfect service;

g. Provide technical exchanging.

Customer visits factory

Engineers go abroad for commissioning

Hot Searches