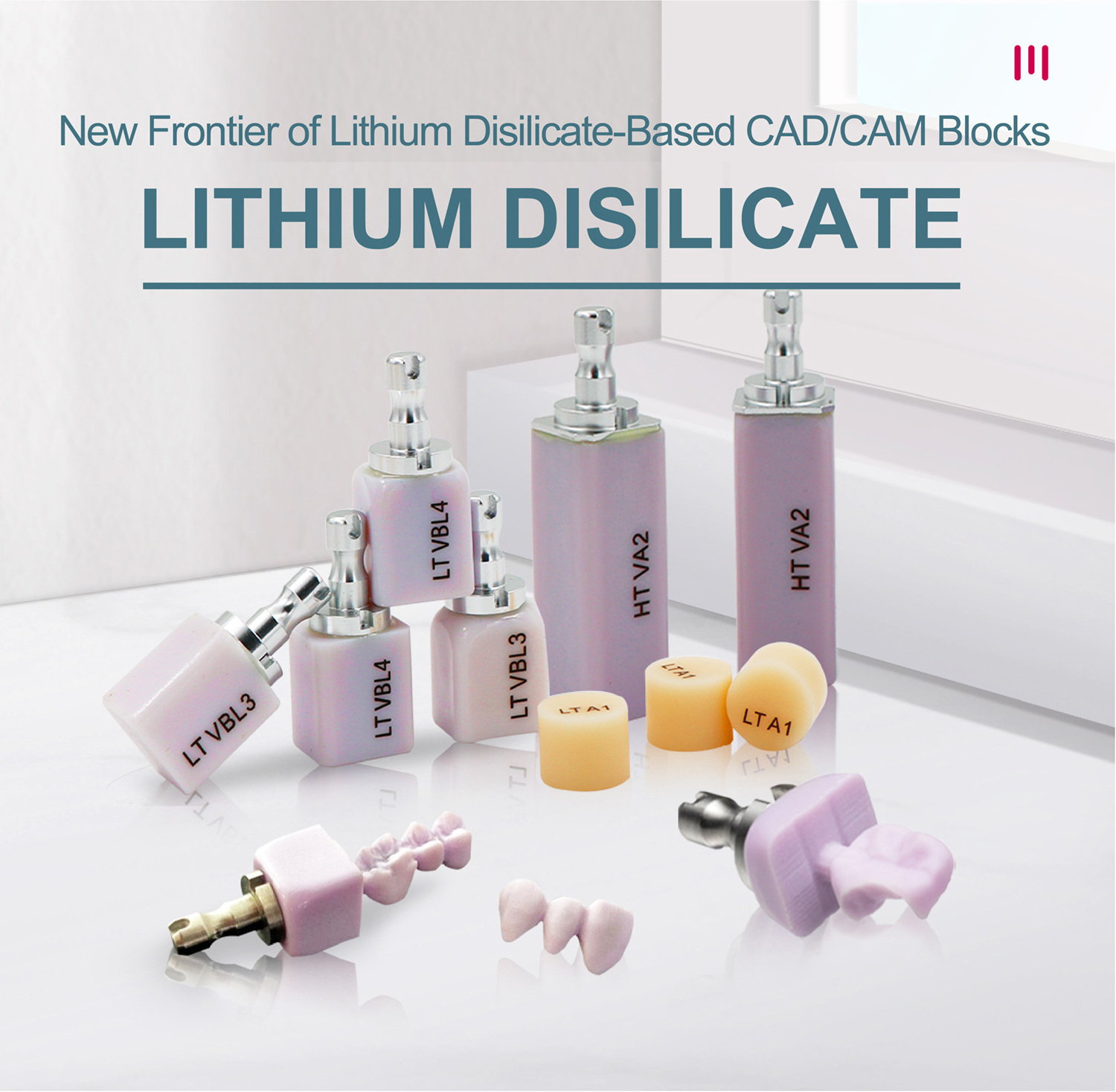

1. Excellent esthetics and high strength of 530 MPa2, efficiently obtained in the dental practice

2. Full range of processing options for your chairside CAD/CAM system

- Product Details

- {{item.text}}

Quick Details

-

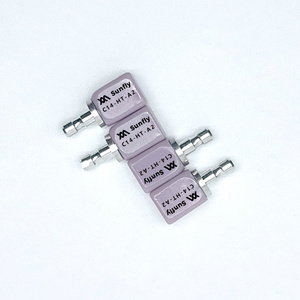

Model Number:

-

Lithium Disilicate, 15-12-10 18-15-13

-

Material:

-

ceramic, Lithium Disilicate

-

Product name:

-

Dental Lab Lithium Disilicate Blocks

-

Place of origin:

-

China

-

Usage:

-

Inlay/onlay/veneer

-

CeO2:

-

<0.5 %

-

flexural Strength:

-

280-360

-

flacture toughness:

-

5.8

-

hardness:

-

1200

-

Certificate:

-

ISO CE

-

CTE Value:

-

Approx8.7

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

Lithium Disilicate, 15-12-10 18-15-13

-

Material:

-

ceramic, Lithium Disilicate

-

Product name:

-

Dental Lab Lithium Disilicate Blocks

-

Place of origin:

-

China

-

Usage:

-

Inlay/onlay/veneer

-

CeO2:

-

<0.5 %

-

flexural Strength:

-

280-360

-

flacture toughness:

-

5.8

-

hardness:

-

1200

-

Certificate:

-

ISO CE

-

CTE Value:

-

Approx8.7

Products

Product Description

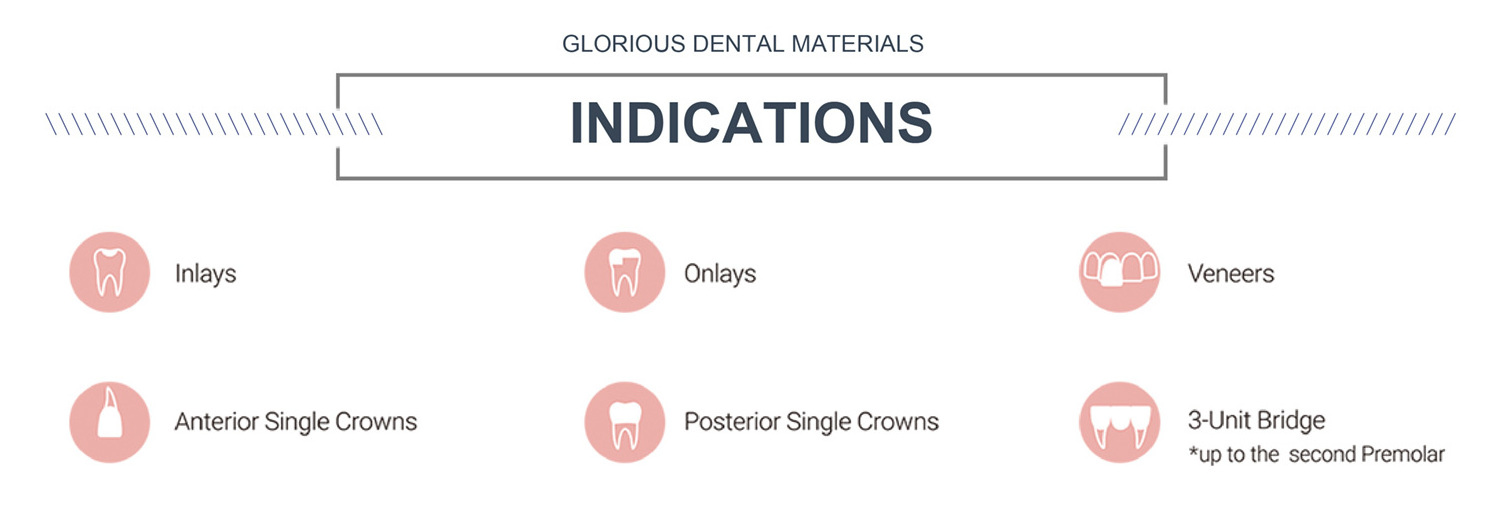

E.max CAD HT - The minimally invasive block:Given their high translucency which is similar to that of natural enamel, HT blocks are ideal for the fabrication of small restorations (e.g. inlays, onlays). Restorations made of HT blocks convince user with their true-to-nature chameleon effect and the exceptional adaptation to the remaining tooth structure.

E.max CAD LT - The versatile block:Given their low translucency which is similar to that of the natural dentin, LT blocks are ideal for the fabrication of larger restorations (e.g. posterior crowns). Restorations made from LT blocks convince users with their lifelike brightness and chroma. This prevents the incorporated restorations from greying.

E.max CAD MO - The classical block:Given their particular opacity, MO blocks are ideally suitable for the fabrication of frameworks on slightly discoloured preparations. They are primarily used in the dental laboratory.

E.max CAD LT - The versatile block:Given their low translucency which is similar to that of the natural dentin, LT blocks are ideal for the fabrication of larger restorations (e.g. posterior crowns). Restorations made from LT blocks convince users with their lifelike brightness and chroma. This prevents the incorporated restorations from greying.

E.max CAD MO - The classical block:Given their particular opacity, MO blocks are ideally suitable for the fabrication of frameworks on slightly discoloured preparations. They are primarily used in the dental laboratory.

Application

Advantages

3. High aesthetic repair effect

4. High chemical stability and binging strength

4. High chemical stability and binging strength

5. Easy milling,prolong the service life of burs

6. Simple and rapid crystallization process to reduce operating time

6. Simple and rapid crystallization process to reduce operating time

7. Adhesive, self-adhesive and conventional cementation options, despending on the restoration type

8. Every time without glaze,the unique color change effect to ensure perfect repair effect

8. Every time without glaze,the unique color change effect to ensure perfect repair effect

A porcelain furnace is used to crystallize the restoration to its final state.

Depending on the final aesthetic requirements of the restoration,an appropriate heating

program should be chosen.Crystallization and glazing are achieved in two steps,dis

played in the two charts below depending on the type of restoration.

Sintering program for crystallization only or crystallization together with glazing,Program

1 or program 2 is available.

Depending on the final aesthetic requirements of the restoration,an appropriate heating

program should be chosen.Crystallization and glazing are achieved in two steps,dis

played in the two charts below depending on the type of restoration.

Sintering program for crystallization only or crystallization together with glazing,Program

1 or program 2 is available.

One -Step Proccess

|

Crystallization only or crystallization together with glazing

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

||||||

|

Starting

temp/℃ |

Dry time

/mm:ss |

Temp increas

ing rate/℃

|

Holding

temp /℃ |

Holding

time /℃ |

Vacuum

start /℃ |

Vacuum

finished /℃ |

||||||

|

400

|

00:30

|

40

|

840

|

07:00

|

550

|

840

|

||||||

Two -Step Proccess

|

Crystallization only or crystallization together with glazing

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

||||||

|

Starting

temp/℃ |

Dry time

/mm:ss |

Temp increas

ing rate/℃ |

Holding

temp /℃ |

Holding

time /℃ |

Vacuum

start /℃ |

Vacuum

finished /℃ |

||||||

|

400

|

06:00

|

90/30*

|

820/840

|

00:10/07:00

|

550/820

|

820/840

|

||||||

Glzaing process

|

Glazing process

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

||||||

|

Starting

temp/℃ |

Dry time

/mm:ss |

Temp increas

ing rate/℃ |

Holding

temp /℃ |

Holding

time /℃ |

Vacuum

start /℃ |

Vacuum

finished /℃ |

||||||

|

400

|

00:30

|

40

|

840

|

03:00

|

550

|

840

|

||||||

Customers feeback

Hot Searches