- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

660V

-

Dimension(L*W*H):

-

not standard

-

Weight (T):

-

0.1 T

-

Power (kW):

-

350

-

Warranty:

-

one year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

scrap melting furnace

-

Other name:

-

Aluminum ingot casting machine

-

Rated power:

-

350KW

-

Input voltage:

-

660V

-

Rated medium voltage:

-

1500V

-

Input power:

-

1250KVA

-

Input water temperature:

-

≤35C

-

Output water temperature:

-

≤55C

-

Delivery time:

-

25 working days

-

Certification:

-

CE,GOST,CU,ISO9001

Quick Details

-

Place of Origin:

-

Henan, China

-

Core Components:

-

Furnace

-

Brand Name:

-

hongteng

-

Voltage:

-

660V

-

Dimension(L*W*H):

-

not standard

-

Weight (T):

-

0.1 T

-

Power (kW):

-

350

-

Warranty:

-

one year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

scrap melting furnace

-

Other name:

-

Aluminum ingot casting machine

-

Rated power:

-

350KW

-

Input voltage:

-

660V

-

Rated medium voltage:

-

1500V

-

Input power:

-

1250KVA

-

Input water temperature:

-

≤35C

-

Output water temperature:

-

≤55C

-

Delivery time:

-

25 working days

-

Certification:

-

CE,GOST,CU,ISO9001

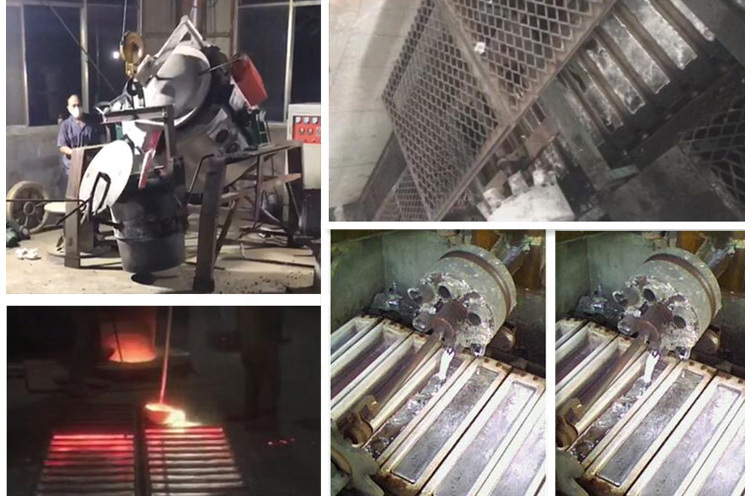

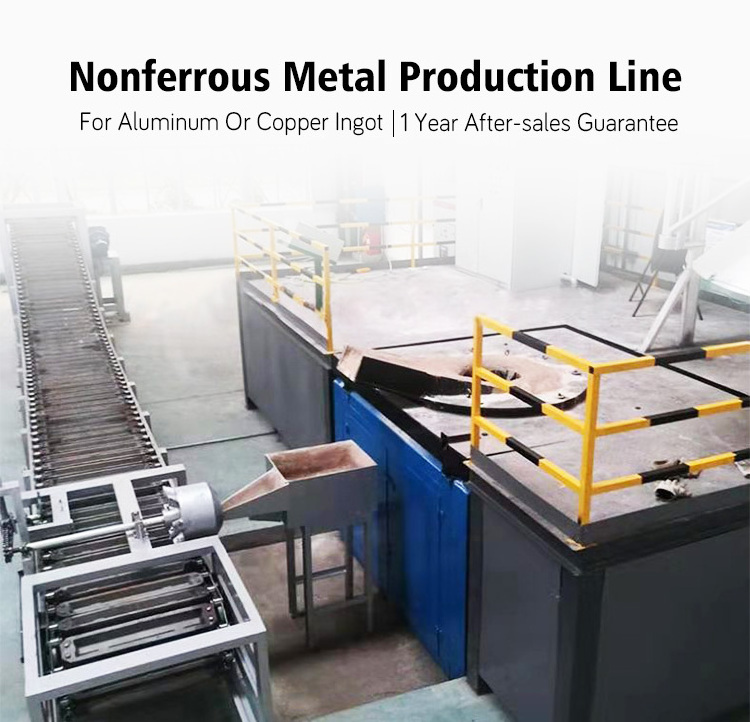

Product Show

1. The equipment is Aluminum ingot casting machine with high production efficiency. It can reach 10Ton per hour

2. Ingots size : 6-30kg (ingots size can designed by customer)

3. The running speed of the equipment is 0-6m/mim adjustable.

4. Aluminum ingots production line total length : 5-24 meters.

1, This equipment is aluminum ingot casting machine with high production efficiency. It can reach 10 Ton per hour

2, Ingots size: 6-30kg (ingots size can designed by customer)

3, The running speed of the equipment is 0-6 m/min adjustable

5, Aluminum ingots production line total length: 5-24 meters

2, Ingots size: 6-30kg (ingots size can designed by customer)

3, The running speed of the equipment is 0-6 m/min adjustable

5, Aluminum ingots production line total length: 5-24 meters

Customer Site

The main feature is stepless speed regulation, automatic liquid filling, ingot uniform, low labor intensity, the output can be increased 20%-30% by using this equipment.

1. Casting machine main structure : U-steel channel welded steel body, conveyor, speed-adjust motor, reducer ,big & small chain wheel & chains, power distribution systems.

2. The driving motor is AC speed regulating motor with electromagnetic or variable frequency mode.

Project site

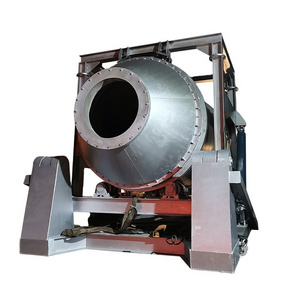

Advange of aluminum scrap melting furnace:

1. Fast melting speed. Melting process can keep the power in the best band operation, which greatly limits to eliminate the adverse effects of the melting rate of new lining.

2. Melting molten steel quality, casting yield is high.

3. High power factor, during machine operation, power factor up to 97%.

4. No interferce of power grids.

5. Low power consumption, saving more than 10% power.

6. 100% success start rate.

7. The main control board adopt connector interface, so it's more convenient to maintenance.

8. Series thyistor inverter adopted, making the SCR damage rate to a minimum.

|

Specifiation for Aluminum Melting Furnace

|

|

|

|

|

||||

|

Model

|

Power(KW)

|

Input Voltage(V)

|

MF Frequency(HZ)

|

Transformer(KVA)

|

||||

|

0.25T

|

180

|

3*380

|

2000

|

250

|

||||

|

0.5T

|

400

|

3*380

|

1500

|

500

|

||||

|

1T

|

700

|

3*660

|

800

|

900

|

||||

|

2T

|

1000

|

3*660

|

600

|

1600

|

||||

|

3T

|

1500

|

3*950

|

500

|

2500

|

||||

|

5T

|

2000

|

3*950

|

500

|

3300

|

||||

Product advantages

1. Provide overall solution and after-sales guarantee.

2. Provide plant desigh, proposal, manufaturing ,shipping, installation and commissioning services.

3.Provide overall equipment layout , aluminum ingots production line process design, electrical circuit layout.

4. Dispatch technicians to provide installation services after the machine arrives until customer is satisfied.

5. Long-term technical support, long-term machine warranty.

Recommend Products

Why Choose Us

Certifications

Hot Searches