- Product Details

- {{item.text}}

Quick Details

-

Ultimate Strength (≥ MPa):

-

0.04

-

Density (kg/m³ ):

-

128

-

Length:

-

3600mm,7200mm

-

Working Temperature:

-

1000-1350℃

-

Fiber Diameter:

-

2μm

-

Shrinkage (1800 ℉, 3h):

-

-3 (1000°C)

-

Thermal Conductivity:

-

0.09(400°C) 0.16(800°C) 0.20(1000°C)

-

Model Number:

-

TEX

-

Brand Name:

-

TEXASPRO

-

Place of Origin:

-

Shanghai, China

-

Product name::

-

Ceramic Wool Insulation Blanket

-

Density::

-

96kg/m3 -140kg/m3

-

Thickness::

-

25mm-50mm

-

Width::

-

610mm

-

Length::

-

3600mm,7200mm

Quick Details

-

Thickness:

-

25mm-50mm

-

Width:

-

610mm

-

Chemical Composition:

-

≤3%

-

Ultimate Strength (≥ MPa):

-

0.04

-

Density (kg/m³ ):

-

128

-

Length:

-

3600mm,7200mm

-

Working Temperature:

-

1000-1350℃

-

Fiber Diameter:

-

2μm

-

Shrinkage (1800 ℉, 3h):

-

-3 (1000°C)

-

Thermal Conductivity:

-

0.09(400°C) 0.16(800°C) 0.20(1000°C)

-

Model Number:

-

TEX

-

Brand Name:

-

TEXASPRO

-

Place of Origin:

-

Shanghai, China

-

Product name::

-

Ceramic Wool Insulation Blanket

-

Density::

-

96kg/m3 -140kg/m3

-

Thickness::

-

25mm-50mm

-

Width::

-

610mm

-

Length::

-

3600mm,7200mm

Ceramic Fiber Blanket

What is Ceramic Fiber Blanket?

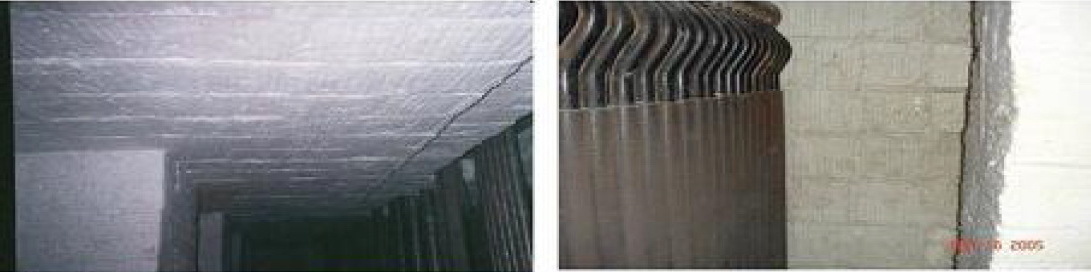

Ceramic Fiber Blanket is manufactured from spun ceramic fiber and is needled to provide exceptional handling strength for high-temperature insulation applications. Blanket is typically offered in three standard grades referred to as commercial, High-Purity, and Zirconia grade. All grades are lightweight and thermally efficient resulting in a material that has the advantage of low heat storage and complete resistance to thermal shock. Blankets are produced in varying dimensions, temperature ratings, and for different applications. Our office also supplies a Bio-Soluble blanket which is environmentally friendly. If you don’t see a specific blanket listed, please contact us directly and we will be happy to provide a custom quote.

Operating at Higher Temperatures?

Ceramic Fiber Blanket manufactured from polycrystalline mullite wool (PCW) rated to a temperature of 3000℉ (1649℃) is now stocked. This grade of Ceramic Fiber Blanket contains no binder, additives, or shot content. Material is RCF free and resistant to most corrosive agents in both oxidizing and reducing atmospheres. This material is highly specialized for the most demanding and extreme temperature requirements

Complex Shapes & Gas Velocities

Ceramic Fiber Blanket Wet Wool (WW) is specifically manufactured for insulating complex shapes and services under high hot gas velocities. Material is permeated with inorganic bonding agents and packaged in a clear polyethylene bag to retain the wet binder during shipping and storage. The manufacturing process results in flexible insulation that can be formed to complex shapes in place and air dries to form a hard, rigid structure. Additionally, the material can be cured by immediate exposure to temperature in application. Material has a dry density of 12-18 lbs/ft3 (190-290 kg/m3).

Specification

Density: 96kg/m3 -140kg/m3

Thickness: 25mm-50mm

Width: 610mm

Length: 3600mm,7200mm

Technical Data sheet

|

Type |

Ordinary |

Standard |

High Purity |

High Aluminium |

Zirconia |

|

|

Classification temperature (°C) |

1100 |

1260 |

1260 |

1360 |

1430 |

|

|

Working Temperature (°C) |

< 1000 |

1050 |

1100 |

1200 |

1350 |

|

|

Color |

white |

spotlessly white |

spotlessly white |

spotlessly white |

spotlessly white |

|

|

Density (kg/m3) |

96

|

96

|

96

|

128

|

128

|

|

|

Shrinkage on heating (%) (24 hours,density as 128/m3) |

-4

|

-3

|

-3

|

-3

|

-3

|

|

|

Thermal conductivity by different temperature (w/m.k) (density as 128kg/m3) |

0.09(400°C)

|

0.09(400°C)

|

0.09(400°C)

0.16(800°C)

|

0.12(600°C)

|

0.16(800°C)

|

|

|

Tensile strength (MPa)

|

0.04 |

0.04 |

0.04 |

0.04 |

0.04 |

|

|

Chemical composition (%) |

AL2O3 |

44 |

46 |

47-49 |

52-55 |

39-40 |

|

AL2O3+SIO2 |

96 |

97 |

99 |

99 |

- |

|

|

AL2O3+SIO2+ZrO2 |

- |

- |

- |

- |

99 |

|

|

ZrO2 |

- |

- |

- |

- |

15-17 |

|

|

Fe2O3 |

<1.2 |

<1.0 |

0.2 |

0.2 |

0.2 |

|

|

Na2O+K2O |

≤0.5 |

≤0.5 |

0.2 |

0.2 |

0.2 |

|

Package:

1) Export Standard package: Two rolls in one woven bag

2) Pack with carton (there is extra cost for carton and loading quantity will be less than woven bag packing)

3) Pack as customer required,we can do OEM Packing

Application:

Typical Applications:

Refining and Petrochemical

Reformer and Pyrolysis Furnaces

Tube Seals, Gaskets and Expansion Joints

High-Temperature Pipe, Duct and Turbine Insulation

Crude Oil Heater Linings

Steel Industry: Furnace Door Linings and Seals

Soaking Pit Convers and Seals

Furnace Hot Face Repairs

Reheat Furnaces,Ladle Covers

Power Generation: Boiler Insulation

Boiler Doors

Reusable Turbine Covers

Pipe Covering

Ceramic Industry: Kiln Car Insulation and Seals

Continuous and Batch Kilns

Other Applications: Insulation of Commercial Dryers and Covers

Veneer Over Existing Refractory

Stress Relieving Furnaces

Glass Furnace Crown Insulation,Fire Protection