- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

15KW

-

Dimension(L*W*H):

-

4000X2500X1800mm

-

Weight (KG):

-

11000

-

Name:

-

Screw Making Metallurgy Machinery

-

Usage:

-

Screw Making

-

Advantage:

-

High Efficiency Metal Forging Equipment

-

COLOR:

-

Customers' Requirement

-

Keyword:

-

Screw Making Metallurgy Machinery

-

Toolholder stroke:

-

55mm

-

distance between stations:

-

80mm

-

MOQ:

-

1set

-

Packing:

-

wooden case

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Auris

-

Machine Type:

-

Screw Making Machine

-

Voltage:

-

380V

-

Power:

-

15KW

-

Dimension(L*W*H):

-

4000X2500X1800mm

-

Weight (KG):

-

11000

-

Name:

-

Screw Making Metallurgy Machinery

-

Usage:

-

Screw Making

-

Advantage:

-

High Efficiency Metal Forging Equipment

-

COLOR:

-

Customers' Requirement

-

Keyword:

-

Screw Making Metallurgy Machinery

-

Toolholder stroke:

-

55mm

-

distance between stations:

-

80mm

-

MOQ:

-

1set

-

Packing:

-

wooden case

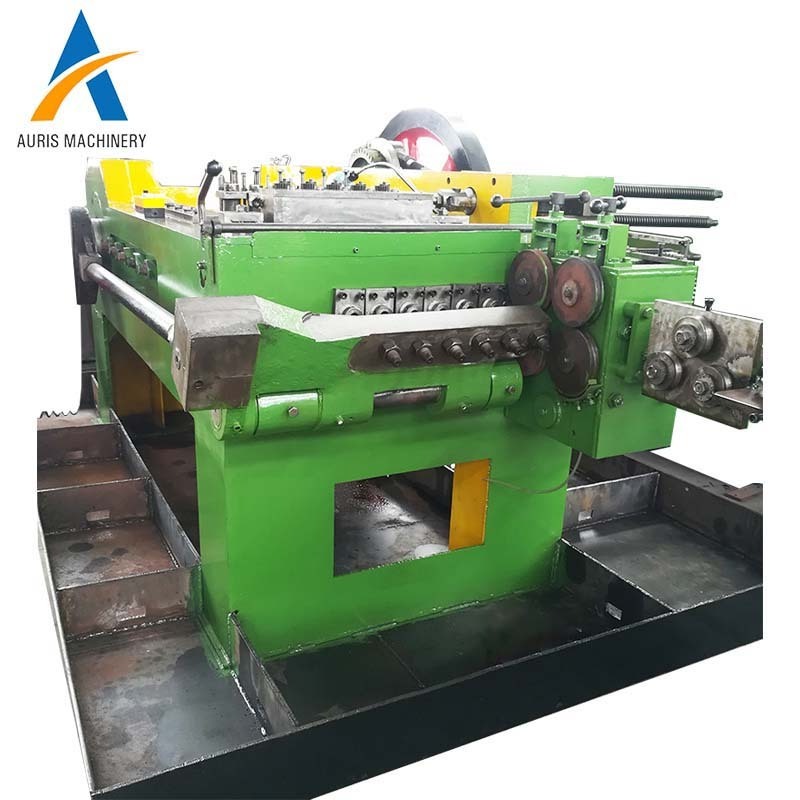

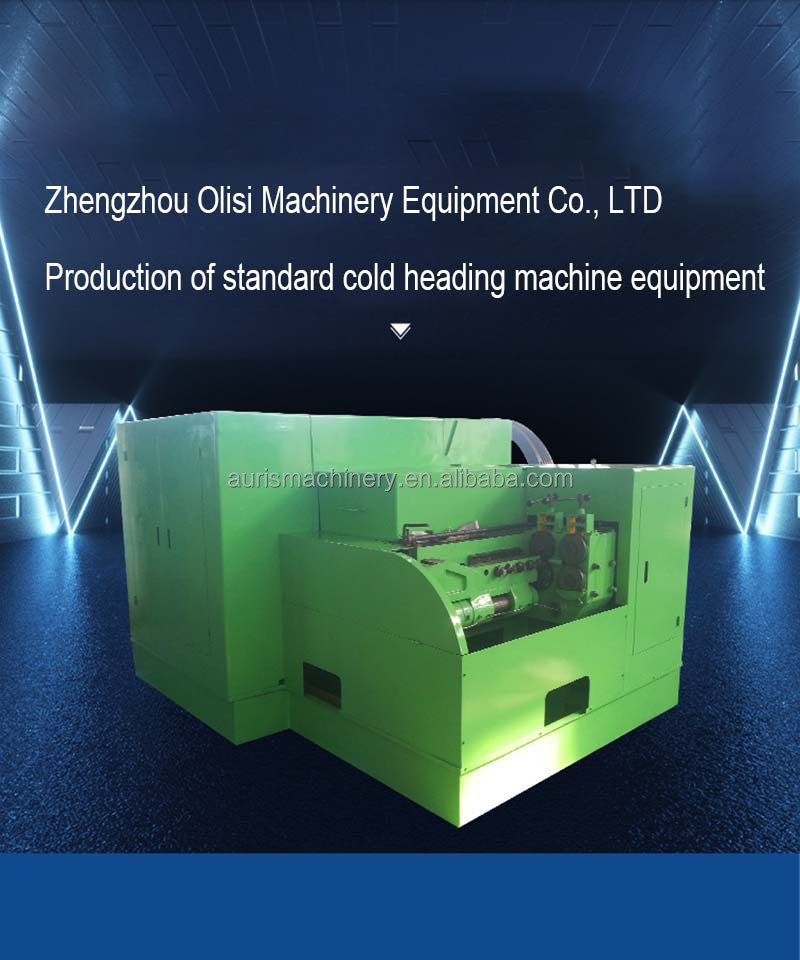

Manufacturer high-speed screw head screw cold forging rivet cold pier machine cold forging machine

Product Description

Features of

cold forging machine

:

1. This machine is a special equipment for producing hexagonal nuts, especially some non-standard parts. 2. The single-sided S-plate cutting material is more stable and powerful, and the time can be adjusted. 3. The new GF series tong shifting mechanism also uses a single S plate to drive the tong frame, which can not only use the shaping method of Taiwanese car, but also the cost-saving method of small material and large deformation, and the transmission is compared with the traditional cold heading machine. more accurate. 4. The mechanical transmission can optionally adopt a bridge-crossing secondary mechanism. 5. Compared with the ordinary Z41 series, this machine has the characteristics of low noise, low consumption, and is used for making special-shaped nuts. 5. This model can be made in a length range of 5- -80MM (customized according to customer requirements)

1. This machine is a special equipment for producing hexagonal nuts, especially some non-standard parts. 2. The single-sided S-plate cutting material is more stable and powerful, and the time can be adjusted. 3. The new GF series tong shifting mechanism also uses a single S plate to drive the tong frame, which can not only use the shaping method of Taiwanese car, but also the cost-saving method of small material and large deformation, and the transmission is compared with the traditional cold heading machine. more accurate. 4. The mechanical transmission can optionally adopt a bridge-crossing secondary mechanism. 5. Compared with the ordinary Z41 series, this machine has the characteristics of low noise, low consumption, and is used for making special-shaped nuts. 5. This model can be made in a length range of 5- -80MM (customized according to customer requirements)

Specification

|

Model

|

A-8GF

|

A-10GF

|

A- 12GF

|

|

Toolholder stroke

|

55mm

|

70mm

|

72mm

|

|

Distance between stations

|

80mm

|

80mm

|

90mm

|

|

Crankshaft eccentricity

|

95mm

|

100mm

|

95mm

|

|

Main slider stroke

|

190mm

|

200mm

|

190mm

|

|

Number of stations

|

6units

|

6units

|

6units

|

|

Productivity

|

90pec/min

|

85pec/min

|

50-75pec/min

|

|

Maximum diameter of cutting material

|

14mm

|

16mm

|

18.5mm

|

|

Maximum size of parts

|

S14

|

S17

|

S19

|

|

Motor

|

15kw

|

18.5kw

|

22KW

|

|

Dimensions

|

2600X2200X1600mm

|

2800X2300X1700mm

|

4000X2500X1800mm

|

|

Weight

|

11000kg

|

17000kg

|

19000kg

|

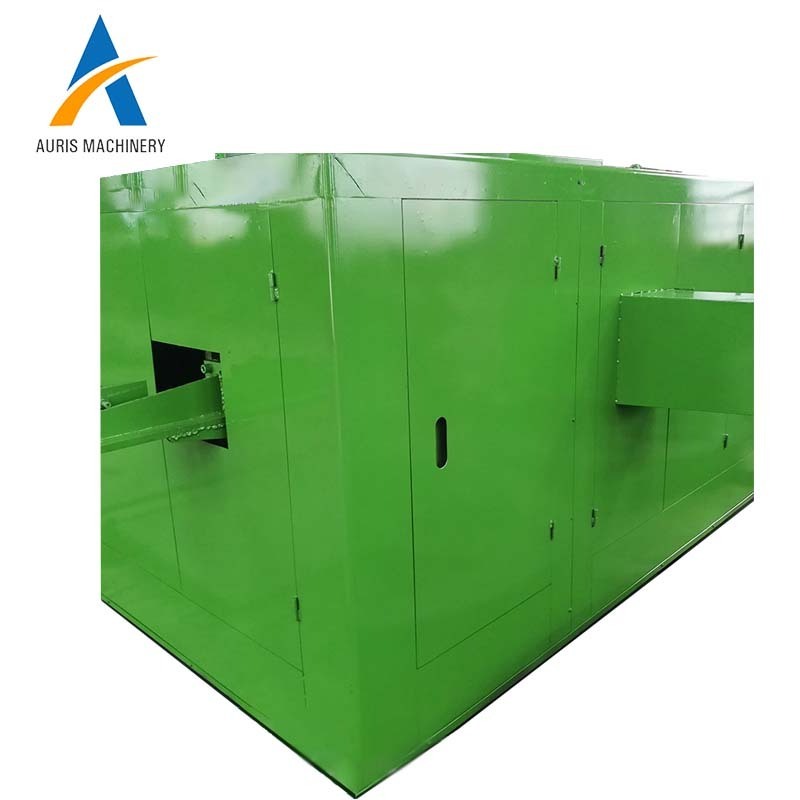

Details Images

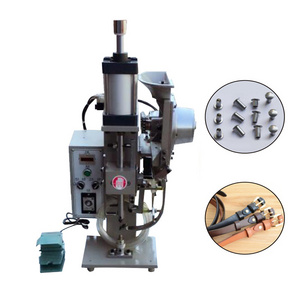

Related products

Packing & Delivery

Hot Searches