- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380/440V

-

Dimension(L*W*H):

-

Customized to the project solution

-

Weight:

-

10000 KG

-

Marketing Type:

-

High quality cooking oil factory

-

Certificate:

-

CE/ISO9001/2000

-

Customized:

-

Accept

-

Supplier:

-

China manufacturer,factory

-

Machine capacity:

-

5-5000T/D and accept customize

-

Application:

-

edible oil production plant

-

Raw material:

-

soybeans,corn gram,sunflower seed,rapeseed,peanut,cottonseed

-

Machine Material:

-

304 stainless steel,Iron,steel

-

After-sales Service Provided:

-

Online Video Technical Support,Engineer's on-site guidance

-

Product name:

-

soy oil making machine

-

Keyword:

-

soybean oil mill project

Quick Details

-

Max Capacity:

-

5000T/D

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Siwei

-

Voltage:

-

380/440V

-

Dimension(L*W*H):

-

Customized to the project solution

-

Weight:

-

10000 KG

-

Marketing Type:

-

High quality cooking oil factory

-

Certificate:

-

CE/ISO9001/2000

-

Customized:

-

Accept

-

Supplier:

-

China manufacturer,factory

-

Machine capacity:

-

5-5000T/D and accept customize

-

Application:

-

edible oil production plant

-

Raw material:

-

soybeans,corn gram,sunflower seed,rapeseed,peanut,cottonseed

-

Machine Material:

-

304 stainless steel,Iron,steel

-

After-sales Service Provided:

-

Online Video Technical Support,Engineer's on-site guidance

-

Product name:

-

soy oil making machine

-

Keyword:

-

soybean oil mill project

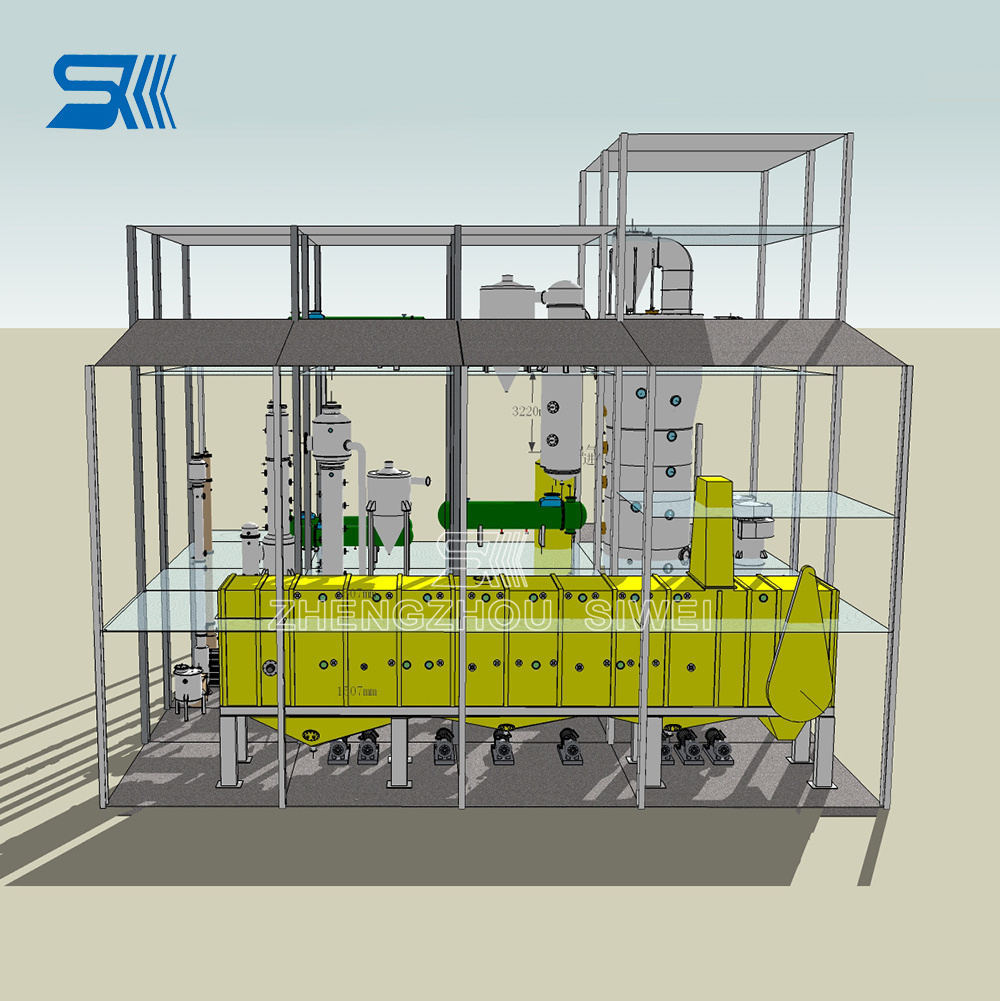

300tpd project for crude soybean oil extraction soybean oil solvent extraction plant soybean oil mill project cost

Oil presser Description

To undertake:

↘

1-8000 TPD soybean rapeseed pre-treatment and Oil extraction project;

↘

1-1200 TPD edible oil refining project.

Siwei oil engineering is a reliable manufacturer of edible oil machine, including screw oil press, hydraulic cold oil press, solvent oil extraction machine, oil refinery machine, and customized cooking oil production line and design full automatic turnkey cooking oil project. More than 30 years of experience in equipment manufacturing and project construction has allowed us to accumulate a wealth of project experience, allowing us to better understand the needs of our customers.

If you need to know anything, ↘ ↘↘ Please contact me now! To got free project solution!

Siwei oil engineering is a reliable manufacturer of edible oil machine, including screw oil press, hydraulic cold oil press, solvent oil extraction machine, oil refinery machine, and customized cooking oil production line and design full automatic turnkey cooking oil project. More than 30 years of experience in equipment manufacturing and project construction has allowed us to accumulate a wealth of project experience, allowing us to better understand the needs of our customers.

If you need to know anything, ↘ ↘↘ Please contact me now! To got free project solution!

⭐

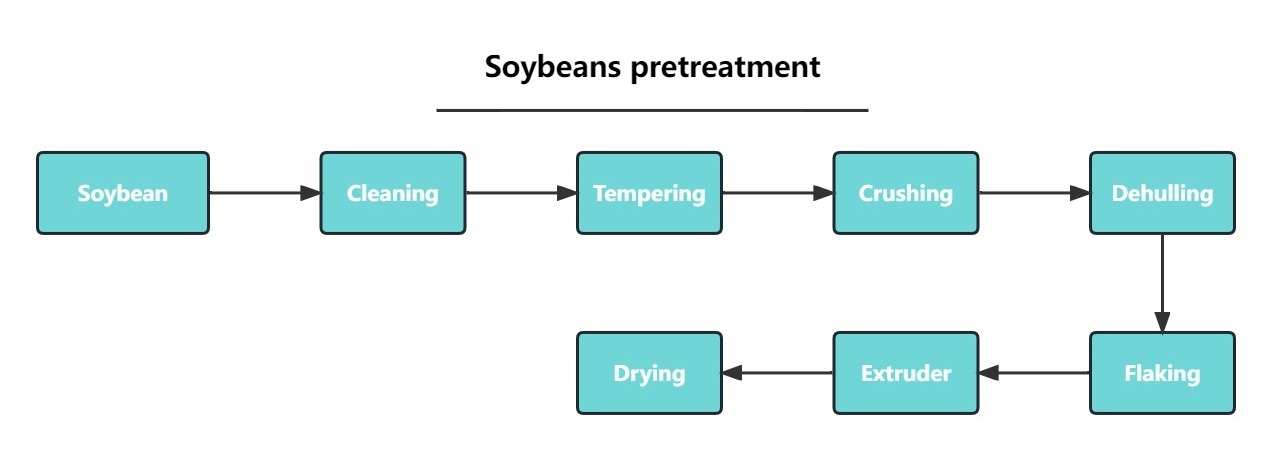

Cleaning

:

Remove most impurities from the material, such as stones, dirt, nails etc., to prepare for the next crushing process, improve crushing efficiency and extend machine life.

⭐

Tempering =

Horizontal dryer

:

Increase the moisture content and temperature of the material,

so that it is uniformly heated to achieve an optimal condition and increase the final oil yield of the material.

Pretratment of edible soybean seed oil extraction project

⭐ Dehulling : Very necessary soybean to dehulling before oil pressing. will be improve oil yield, crude oil quality, and meal quality, while reducing production energy consumption and edible oil equipment wear.

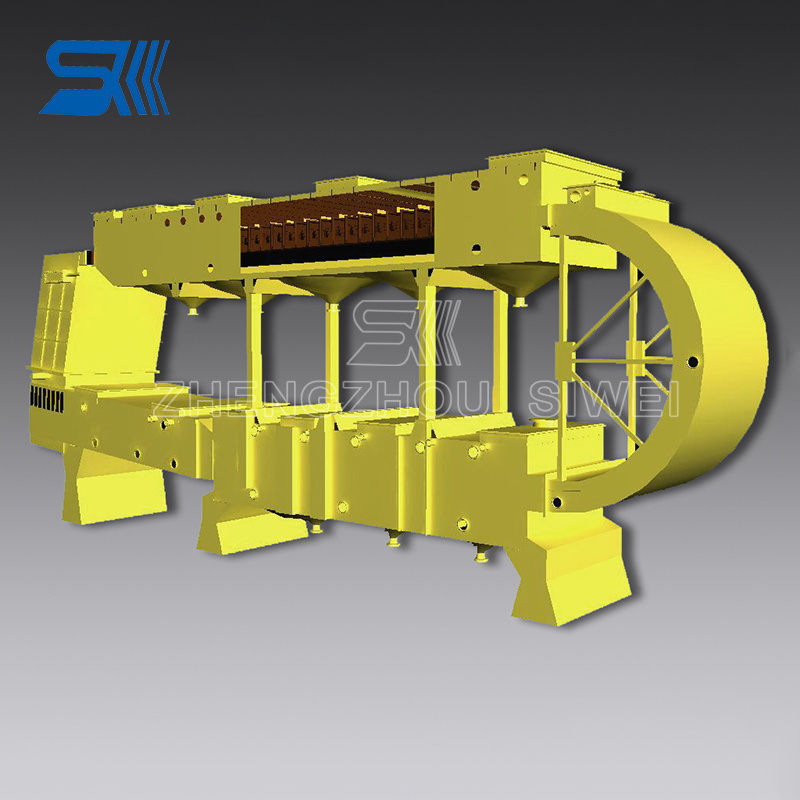

⭐ Flaking : The oilseeds is pressed into flakes through the flaking roll, which has a larger contact area with the solvent for better oil discharge.

Soybean should be pretreated in a raw material processing plant, Oilseeds through flaking and extruder to the best processing state we will use solvent extraction to obtain more oil from the cake.

⭐

Crushing

:

After crushing process soybean will broken into small pieces, which improves the efficiency of the material being pressed.

⭐ Dehulling : Very necessary soybean to dehulling before oil pressing. will be improve oil yield, crude oil quality, and meal quality, while reducing production energy consumption and edible oil equipment wear.

⭐ Flaking : The oilseeds is pressed into flakes through the flaking roll, which has a larger contact area with the solvent for better oil discharge.

⭐

Extruder

:

Soybean in the extrusion machine by extruder, will be inactivating various enzymes in soybean, so increase solvent extraction production capacity, improve oil yield, reduce steam consumption and lower production cost.

⭐

Drying

:

Decrease the moisture content of the soybean flake to Adjust to optimal level, For increase the final oil output.

Extraction process of edible oil extraction project

⭐

The specific design depending for your oil seeds of processing plan.

⭐

Extraction

:

Our machine adopt an organic solvent that can dissolve the oil, through the material spray, soak, so that the oil will be extracted from the oil-bearing seeds.

⭐

DTDC

:

By continuously the multi-layered steam heating, the heat obtained by the solvent in the wet mash is vaporized, thereby separating the solvent from the wet meal.

⭐

Evaporation

:

Difference between the boiling point of the oil and the solvent is used to separate the solvent and the oil.

⭐

Stripper

:

The separated solvent can be dissolved in the selected paraffin or solvent and recovered.

Refining process of edible oil refinery line

It contains large quantity of impurities in the crude oil for to get clean edible oil, we need use further oil refining process.The most important thing is that enhancing the nutritional value of edible oils has great benefits for human health.

⭐

Deacidification and Degumming

:

This step is mainly to remove the excess acid in the grease.

⭐

Decolorization

:

The decolorization process greatly enhances the oxidation stability of the oil, and this process also has a great influence on the subsequent deodorization process of the oil.

⭐

Deodorization

:

Deodorization of oil and fat not only removes odor substances in oil, but also improves the safety of oils and fats.

⭐

Filteration:

Miscella mixed by oil and clay from bleaching tower is pumped into decolorizing filter.

⭐

Dewaxing process

:

Bleached oil enter into crystallizing tank through heat exchanger and begin the cooling crystallization process.

Oilseed

Different oilseeds are processed in different technical, and Different capacities require different equipment, So

If you need a set of equipment to deal with a variety of oilseeds, you need to determine the main oilseeds to be processed

, we will be based on it to design a solution.

Delivered project display

Siwei oil engineering

is an expert in designing vegetable oil production line, including

sunflower oil production line, soybean oil production line, peanut oil production line, palm oil production line, and more.

With years of experience in exporting, designing, and installation of both small and large oil production line across the world. We offer professionally customized

vegetable oil production line of 5TPD to 8000TPD capacities

for soybean and rapeseed at the most competitive prices.

⭐

Overseas sucessful cases show

:

Hot Searches