- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

AJR

-

Material:

-

stainless steel

-

Accuracy:

-

1.5%

-

Application:

-

gas

-

Normal diameter:

-

DN10-DN3000

-

nominal pressure:

-

1.6MPa

-

display:

-

LCD

-

Pwer supply:

-

220vac/24vdc

-

Signal output:

-

pulse/4-20mA

-

Protection class:

-

IP65

-

Connection:

-

flange/insertion

Quick Details

-

Type:

-

variable area gas flowmeters

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Anjun

-

Model Number:

-

AJR

-

Material:

-

stainless steel

-

Accuracy:

-

1.5%

-

Application:

-

gas

-

Normal diameter:

-

DN10-DN3000

-

nominal pressure:

-

1.6MPa

-

display:

-

LCD

-

Pwer supply:

-

220vac/24vdc

-

Signal output:

-

pulse/4-20mA

-

Protection class:

-

IP65

-

Connection:

-

flange/insertion

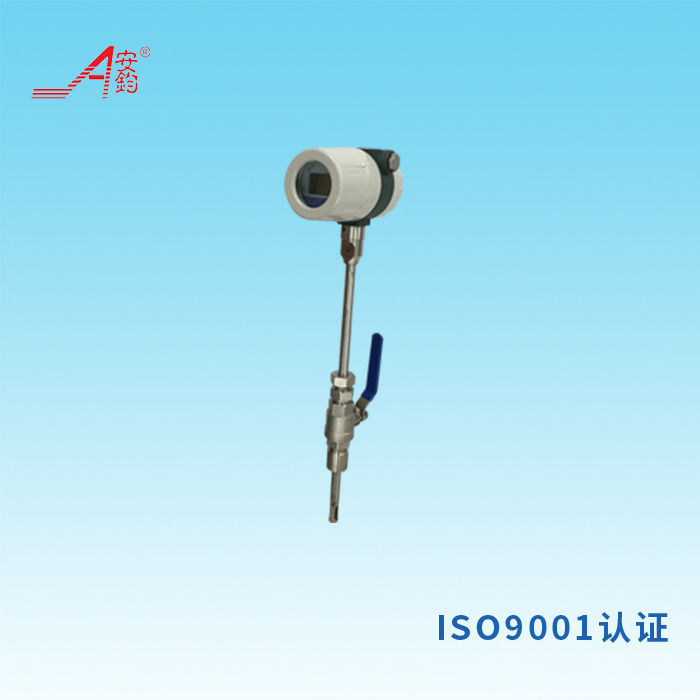

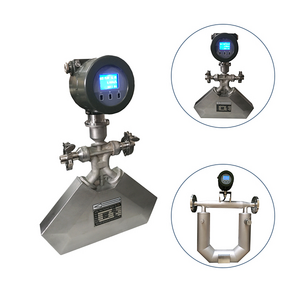

Products Description

Application

(1)Pipe gas in the urban public works, such as the coal gas, natural gas, liquefied gas, etc

(2)Boiler flue gas and wastewater treatment system gas of the environment protection center

(3)Boiler flue gas and wastewater treatment system gas of the environment protection center

(4)Air, ammonia, and oxygen of the metallurgy, kerosene and petrifaction industries

(5)Compressed air, boiler blast and induced air of the papermaking, printing and dyeing and chemical fiber industries.

(6)Ventilation system of the food industry and medical industry

(7)Carbon dioxide treatment, and hot air in the bottle sterilizer

(2)Boiler flue gas and wastewater treatment system gas of the environment protection center

(3)Boiler flue gas and wastewater treatment system gas of the environment protection center

(4)Air, ammonia, and oxygen of the metallurgy, kerosene and petrifaction industries

(5)Compressed air, boiler blast and induced air of the papermaking, printing and dyeing and chemical fiber industries.

(6)Ventilation system of the food industry and medical industry

(7)Carbon dioxide treatment, and hot air in the bottle sterilizer

principles

There are 2 in-built platinum thermistors at the measuring end of the thermal gas mass flowmeter, one for the heat source and one for temperature measurement. When the measured gas passes, it will bring certain heat; temperature difference will rise between 2 thermistors and the temperature difference and flow size will have some relationship.Accordingly, its working principle is called the constant temperature difference method in short.

Main characteristics

It is applicable for single and mixed gas measurement,which can be installed at the round, rectangular and square pipelines with large caliber. l It is applied with the platinum thermistor sensor with new patent technology. l It is applied with the special mass data algorithm and high performance microprocess chips. l It is applied with wide range ratio and extra-low lower limit of speed. l It has high accuracy and good repeatability. l It has no movable parts, thus, its vibration impact can be neglected. l The requirement on the straight pipe section in front and at the back of the flowmeter is not strict, 5D for the front part and 3D for the rear part are acceptable. It is unrelated to the gas temperature and pressure, and the gas mass flow can be directly measured without temperature and pressure compensation. l With the LCD widescreen display, it can directly display the instantaneous flow and accumulated flow. It is available for continuous

assembling/disassembling,which has convenient maintenance.

|

Specifications

|

|

|

|

AJR thermal mass gas flow meter

|

|

|

|

Material

|

steel

|

|

|

DN

|

15-3000mm

|

|

|

Flow rate

|

0-120m/s

|

|

|

Pressure

|

20Mpa Max

|

|

|

Accuracy

|

1.5%

|

|

|

Application

|

gas

|

|

|

Normal Diameter

|

DN10-DN3000

|

|

|

Nominal Pressure

|

1.6MPa

|

|

|

Display

|

LCD

|

|

|

Power Supply

|

220vac/24vdc

|

|

|

Signal Output

|

pulse/4-20mA

|

|

|

Protection Class

|

IP65

|

|

|

Connection

|

flange/insertion

|

|

Special features

*

No need for separate

temperature or pressure transmitters

* High accuracy and repeatability

* Turndown of 100 to 1 and resolution as much as 1000 to 1

* Low –end sensitivity-measure as low as 5 SFPM

* Negligible pressure drop-will not impede the flow or waste energy

* No moving parts-eliminates costly bearing replacements and prevents undetected accuracy shifts

* Dirt insensitive-provides sustained performance

* Low cost of ownership

* Ease of installation and convenient mounting hardware

* Turndown of 100 to 1 and resolution as much as 1000 to 1

* Low –end sensitivity-measure as low as 5 SFPM

* Negligible pressure drop-will not impede the flow or waste energy

* No moving parts-eliminates costly bearing replacements and prevents undetected accuracy shifts

* Dirt insensitive-provides sustained performance

* Low cost of ownership

* Ease of installation and convenient mounting hardware

|

Technical Data

|

|

|

||

|

|

Insertion

|

In-Line

|

||

|

Media

|

All gases except acetylene

|

|

||

|

Pipe Size

|

DN80~6000 mm

|

DN15~2000 mm

|

||

|

Flow Range

|

0.5~100 Nm/s

|

|

||

|

Accuracy

|

±1%

|

|

||

|

Temperature

|

Sensor:-10~+200°C,-10~+350°C

Transmitter:-20~+45°C

|

|

||

|

Pressure

|

≤2.5Mpa

|

≤4.0Mpa

|

||

|

Power

|

Integral:DC24V or AC220V

|

|

||

|

Responsiveness

|

1S

|

|

||

|

Output

|

4-20 mA, RS-485

|

|

||

|

Material of pipe

|

CS, SS, Plastic

|

|

||

|

Content of display

|

Mass flow rate, gas flow rate, total flow rate, total time

|

|

||

|

Dimension

|

213*185*107mm, 160*80*160mm

|

|

||

|

Protection of transmitter

|

IP65, IP52

|

|

||

|

Protection of meter

|

IP67

|

|

||

|

Explosion proof

|

Exd II CT4

|

|

||

|

Material of sensor

|

SS

|

SS, CS

|

||

Recommend Products

Hot Searches