- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

5000 kg

-

Place of Origin:

-

Jiangsu, China

-

Power:

-

9200

-

Dimension(L*W*H):

-

6*2.2*1.6m

-

Warranty:

-

2 years warranty

-

Sheet Thickness (mm):

-

0.5~1.2mm

-

Production Capacity:

-

100Set/Month

-

After-sales Service Provided:

-

Overseas third-party support available

-

Type:

-

Pipe Production Line

-

Application:

-

Energy Supply Pipe

-

Pipe Material:

-

Carbon Steel

-

Name:

-

spiral hvac duct machine

-

USING:

-

wind Pipe production line 3

-

motor brand:

-

Siemens Motor

-

metal feeding frame:

-

1 set

-

leveler grooving roller machine:

-

1 set

-

Certification:

-

ISO and CE

Quick Details

-

Marketing Type:

-

Hot Product 2021

-

Brand Name:

-

KRRASS

-

Condition:

-

New, New

-

Weight:

-

5000 kg

-

Place of Origin:

-

Jiangsu, China

-

Power:

-

9200

-

Dimension(L*W*H):

-

6*2.2*1.6m

-

Warranty:

-

2 years warranty

-

Sheet Thickness (mm):

-

0.5~1.2mm

-

Production Capacity:

-

100Set/Month

-

After-sales Service Provided:

-

Overseas third-party support available

-

Type:

-

Pipe Production Line

-

Application:

-

Energy Supply Pipe

-

Pipe Material:

-

Carbon Steel

-

Name:

-

spiral hvac duct machine

-

USING:

-

wind Pipe production line 3

-

motor brand:

-

Siemens Motor

-

metal feeding frame:

-

1 set

-

leveler grooving roller machine:

-

1 set

-

Certification:

-

ISO and CE

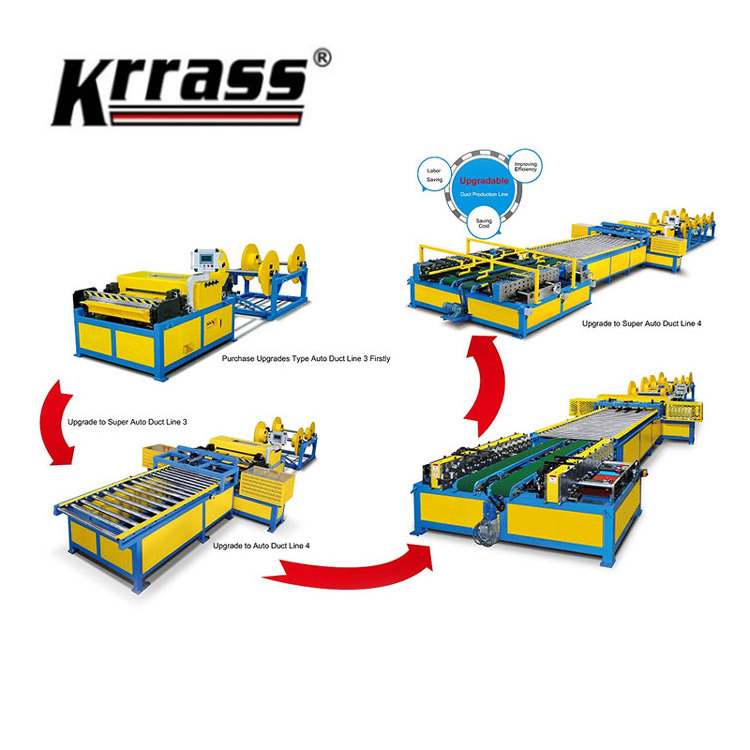

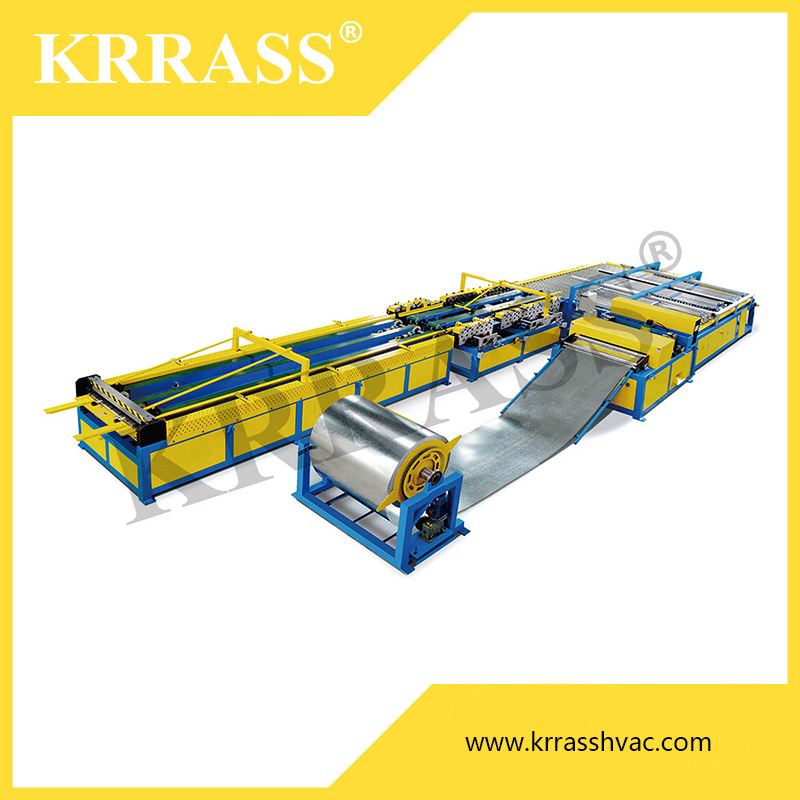

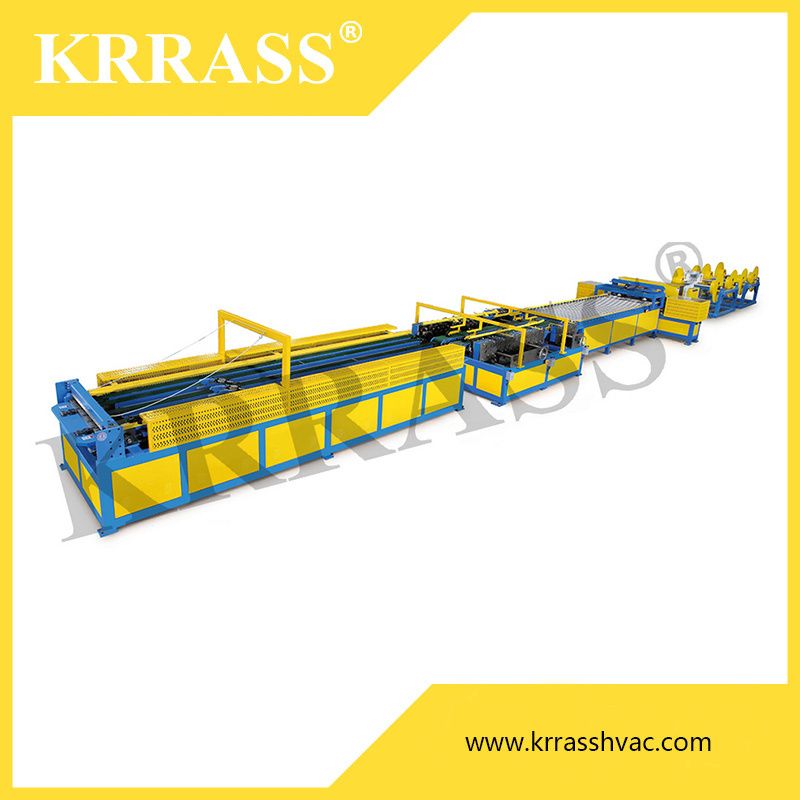

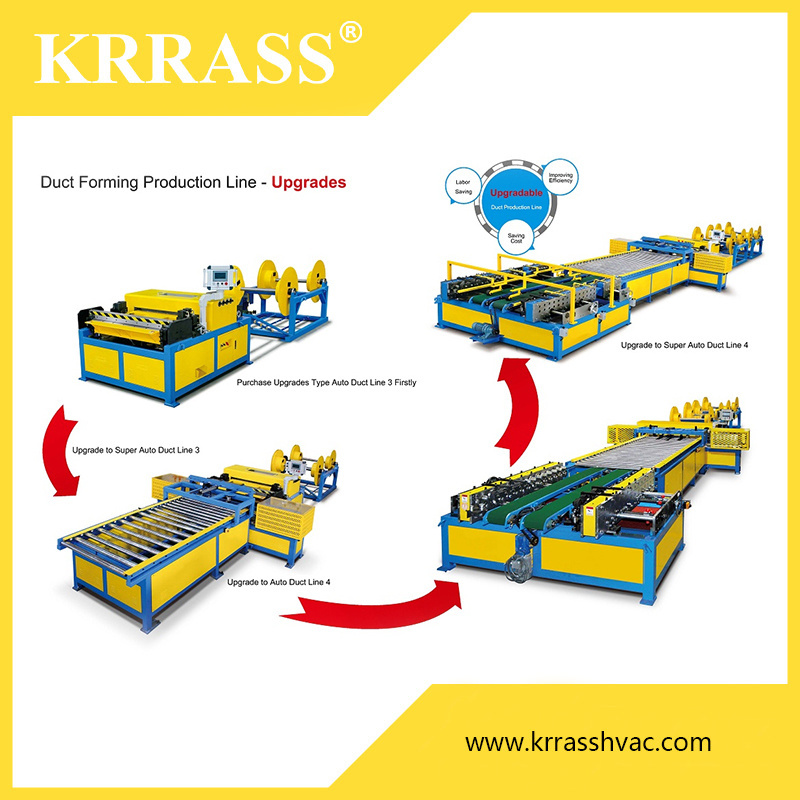

| 1. Product Description |

Watch Video on Youtube

https://www.youtube.com/channel/UCba0m8-b9oSiWIoD2tbsW6w

|

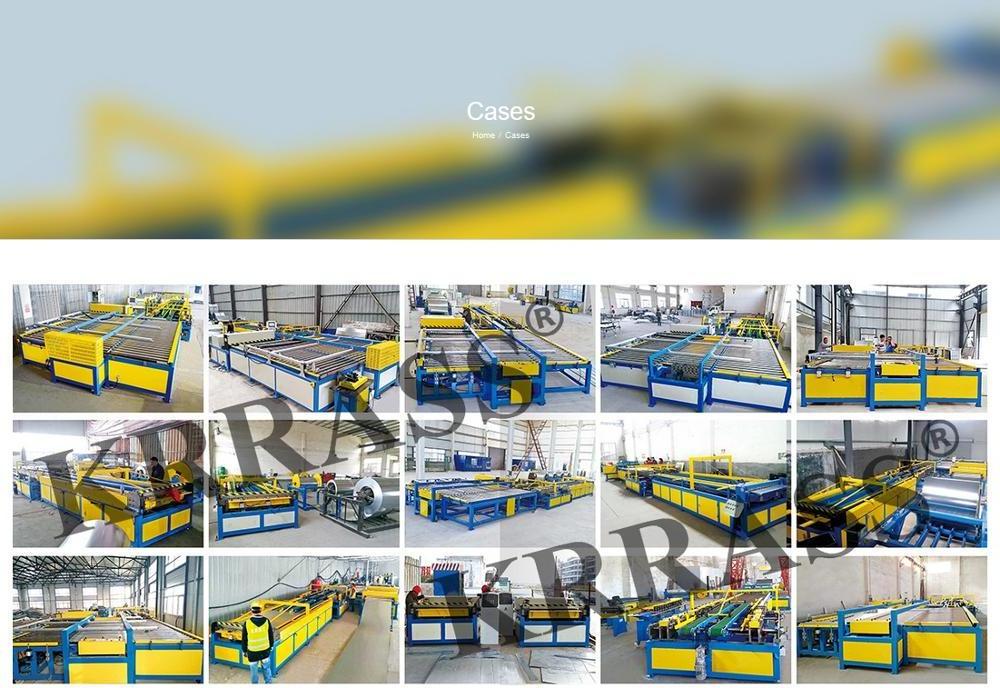

2. Cases & Videos

|

Watch Video on Youtube

https://www.youtube.com/channel/UCba0m8-b9oSiWIoD2tbsW6w

|

3. FAQ

|

Check Our Packing Video on Youtube

https://youtu.be/8cmx2DUqKV4

| 7. About Us |