- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

JG

-

Model Number:

-

A36 Q235 Q345

-

Width:

-

1250mm -1500mm or customed

-

Length:

-

customized

-

Product Name:

-

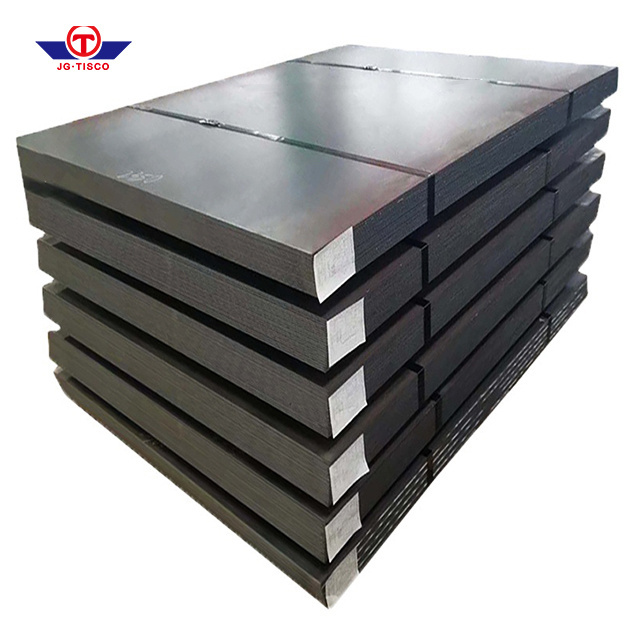

Hot Rolled Steel Plate

-

MOQ:

-

1 Ton

-

Material:

-

Q195/Q235/Ss400/SPHC/SAE1006

-

standard:

-

AiSi, ASTM, bs, DIN, GB, JIS, AiSi, ASTM, bs, DIN, GB, JIS

-

Transport Package:

-

Standard Sea Worthy Package

-

Technology:

-

Cold Rolled.hot Rolled

-

Usage:

-

Construction Structure

-

Payment term:

-

30%TT Advance + 70% Balance

Quick Details

-

Grade:

-

carbon steel

-

Tolerance:

-

±1%

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JG

-

Model Number:

-

A36 Q235 Q345

-

Width:

-

1250mm -1500mm or customed

-

Length:

-

customized

-

Product Name:

-

Hot Rolled Steel Plate

-

MOQ:

-

1 Ton

-

Material:

-

Q195/Q235/Ss400/SPHC/SAE1006

-

standard:

-

AiSi, ASTM, bs, DIN, GB, JIS, AiSi, ASTM, bs, DIN, GB, JIS

-

Transport Package:

-

Standard Sea Worthy Package

-

Technology:

-

Cold Rolled.hot Rolled

-

Usage:

-

Construction Structure

-

Payment term:

-

30%TT Advance + 70% Balance

Products Description

|

Product Name

|

Carbon Steel plate

|

|

Material Grade

|

A36 A53 Q235 Q195 SS400 A53b

|

|

Place of Origin

|

Shandong,China(Mainland)

|

|

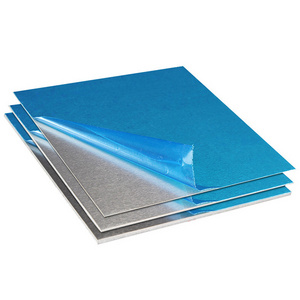

Surface Treament

|

Coated

|

|

Coating Material

|

PE,SMP,HDP,PVDF

|

|

Color

|

All RAL colors or customers sampels color

|

|

Top Coating Thickness

|

15μm-25μm

|

|

Back Coated Thickness

|

5μm-20μm

|

|

Thickness

|

0.2-4mm

|

|

Width

|

600-2000mm

|

|

Coil ID

|

508/610mm

|

|

Coil Weight

|

3-8 tons

|

|

Packaging

|

Standard export seaworthy packing

|

|

Transport

|

Ocean Shipping

|

Product Applications

Carbon steel manufacturing process:

The smelting of carbon steel is usually carried out in converter and open hearth. Converters generally smelt ordinary carbon steel, while open furnaces smelt all kinds of high-quality steel. The technology of oxygen top blow converter is developing rapidly and it can replace open hearth furnace. The refined liquid steel is injected into the ingot mold to obtain various ingot. After the ingot is forged or rolled, it is processed into plates, strips, bars, and sections of various sectional shapes. Carbon steel is usually used directly in the hot rolled state. When used for manufacturing tools and various machine parts, it needs to be heat treated according to the requirements of use; As for steel castings, most of them are heat-treated.

The smelting of carbon steel is usually carried out in converter and open hearth. Converters generally smelt ordinary carbon steel, while open furnaces smelt all kinds of high-quality steel. The technology of oxygen top blow converter is developing rapidly and it can replace open hearth furnace. The refined liquid steel is injected into the ingot mold to obtain various ingot. After the ingot is forged or rolled, it is processed into plates, strips, bars, and sections of various sectional shapes. Carbon steel is usually used directly in the hot rolled state. When used for manufacturing tools and various machine parts, it needs to be heat treated according to the requirements of use; As for steel castings, most of them are heat-treated.

Application of carbon steel:

Carbon steel, carbon tool steel, spring steel and all kinds of waste materials with carbon content of 0.1%-1.2% can be used as metallurgical steel carbon and carburizing steel materials. The following points should be noted when choosing carbon steel return material.

1. Steel ingot riser, hot rolling forging cutting head, etc., in which the content of phosphorus and sulfur is higher. The dosage should be controlled when smelting low phosphorus and sulfur alloy steel.

2. The components of scrap, waste wire and strip, waste steel and so on are not accurate. The selection should be careful, and it is best to use after remelting (washing furnace).

3.The use of carbon steel scrap steel should be carried out spark identification, classification use.

The use of carbon steel:

Q195 is used for manufacturing parts with small load, iron wire, iron ring, cushion iron, cotter pin, tie rod, stamping parts and welding parts, etc.

Q215A is used in the manufacture of tie rod, ring, gasket, infiltration ring, carburized parts and welding parts.

Q235AA, B class is used for the manufacture of metal structural parts, carburizing parts or carburizing parts with low core strength requirements, tie rods, connecting rods, hooks, couplings, bolts, nuts, sleeves, shafts and connectors; Class C and D are used to make important welded structural parts.

Q255A is used to manufacture rotary shaft, mandrel, hook, tie rod, rocker, wedge and other parts with low strength requirements. The negative weldability is not bad.

Q275 is used to manufacture shaft, sprocket, gear, hook and other high strength parts.

Carbon steel, carbon tool steel, spring steel and all kinds of waste materials with carbon content of 0.1%-1.2% can be used as metallurgical steel carbon and carburizing steel materials. The following points should be noted when choosing carbon steel return material.

1. Steel ingot riser, hot rolling forging cutting head, etc., in which the content of phosphorus and sulfur is higher. The dosage should be controlled when smelting low phosphorus and sulfur alloy steel.

2. The components of scrap, waste wire and strip, waste steel and so on are not accurate. The selection should be careful, and it is best to use after remelting (washing furnace).

3.The use of carbon steel scrap steel should be carried out spark identification, classification use.

The use of carbon steel:

Q195 is used for manufacturing parts with small load, iron wire, iron ring, cushion iron, cotter pin, tie rod, stamping parts and welding parts, etc.

Q215A is used in the manufacture of tie rod, ring, gasket, infiltration ring, carburized parts and welding parts.

Q235AA, B class is used for the manufacture of metal structural parts, carburizing parts or carburizing parts with low core strength requirements, tie rods, connecting rods, hooks, couplings, bolts, nuts, sleeves, shafts and connectors; Class C and D are used to make important welded structural parts.

Q255A is used to manufacture rotary shaft, mandrel, hook, tie rod, rocker, wedge and other parts with low strength requirements. The negative weldability is not bad.

Q275 is used to manufacture shaft, sprocket, gear, hook and other high strength parts.

Hot Searches