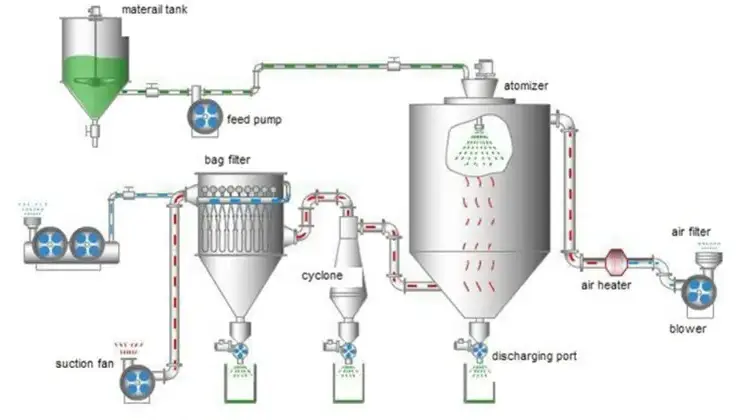

The air is filtered and heated into the top of the dryer air distributor, hot air into the spiral evenly into the drying chamber.

The material liquid is sprayed into a finely atomized liquid droplet through the high-speed centrifugal nebulizer at the top of the tower body, and can be contacted with the hot air in a very short time and can be dried into finished products. The finished product is continuously discharged from the bottom of the drying tower and the cyclone, and the exhaust gas is drained by the draft fan.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/UPON

-

Power:

-

Accroding to model

-

Dimension(L*W*H):

-

Accroding to model

-

Weight (KG):

-

500

-

Marketing Type:

-

Available

-

Product name:

-

Spray Dryer Machine

-

Keywords:

-

Spray dry

-

Function:

-

Drying+Dehumidity

-

After-sales Service Provided:

-

Online Support

-

Usage:

-

Food Used

-

MOQ:

-

1 Set

-

Heating source:

-

Electricity Steam Oil Gas

-

Advantage:

-

High Working Effiency

Quick Details

-

Type:

-

Spray Drying Equipment

-

Place of Origin:

-

Henan

-

Brand Name:

-

WKS

-

Voltage:

-

220V/380V/UPON

-

Power:

-

Accroding to model

-

Dimension(L*W*H):

-

Accroding to model

-

Weight (KG):

-

500

-

Marketing Type:

-

Available

-

Product name:

-

Spray Dryer Machine

-

Keywords:

-

Spray dry

-

Function:

-

Drying+Dehumidity

-

After-sales Service Provided:

-

Online Support

-

Usage:

-

Food Used

-

MOQ:

-

1 Set

-

Heating source:

-

Electricity Steam Oil Gas

-

Advantage:

-

High Working Effiency

Products Description

Working Principle

High-speed drying:

the surface area of liquid material is greatly increased after atomization, achieving instantaneous evaporation

of 95% -98% water in the hot air flow, drying time only takes a few seconds, especially for heat-sensitive materials.

Products achieve good uniformity, mobility, and solubility, and also achieve purity, good quality. The production process is simplified and the operation control is convenient. For liquid materials with the moisture content of 40-90%can be dried into powder products just with one time, do not need grinding and screening after drying, reduce production processes and improve product purity. The product size, bulk density, moisture, in a certain range can be adjusted by changing operating conditions, control and management are very convenient.

The telescopic CIP nozzle covers the main tower, pipeline, and cyclone collector in all directions, which is convenient for cleaning, easy to operate, prevents pollution, and ensures compliance with GMP operating standards.

Product Features

1.Finished products have high quality and purity, good uniformity,good flow capability and solubility advantages.

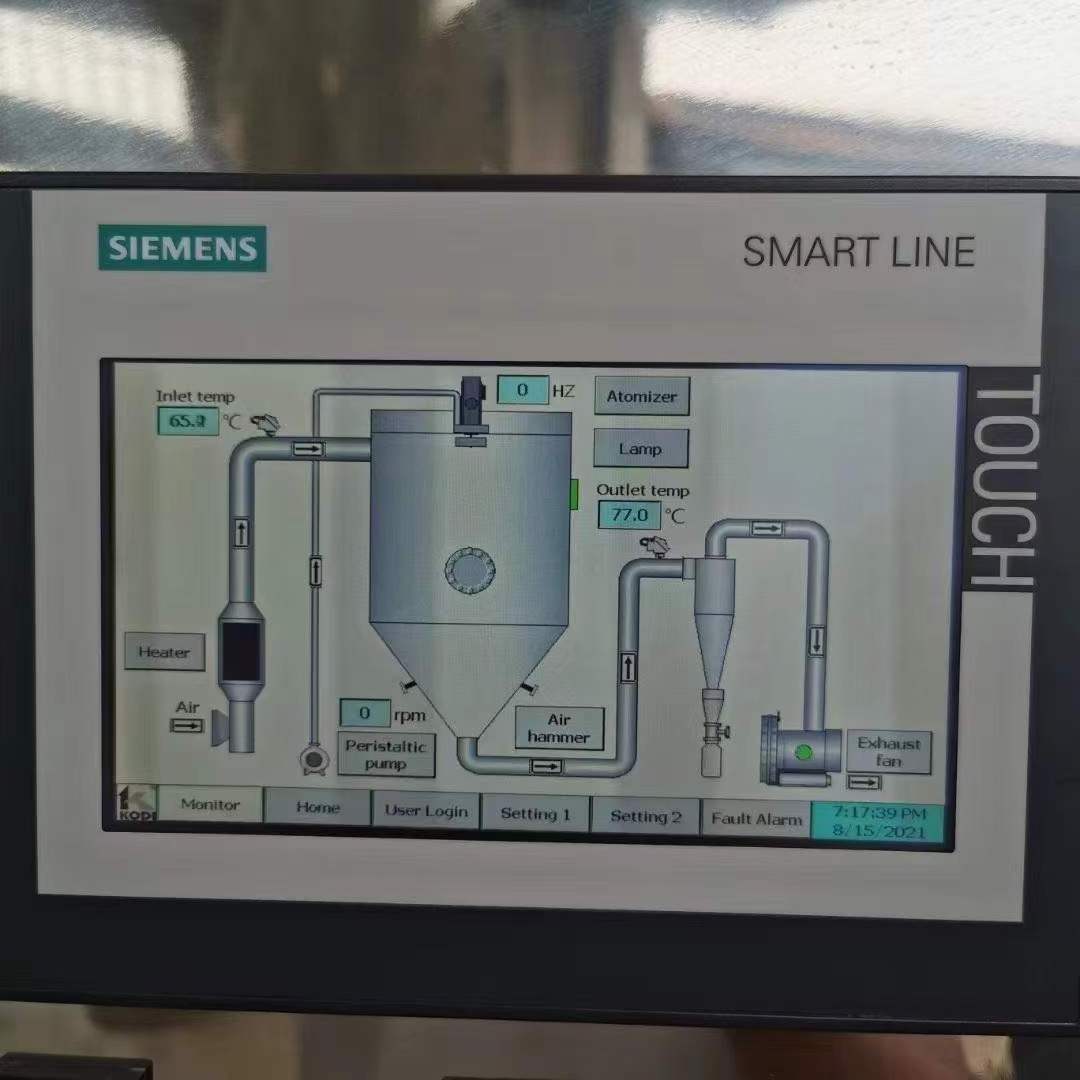

2.Simple and stable operation,convenient control and debugging,easy to achieve automatic operation.

3.Drying speed is rapid.When liquid raw material is atomized,the surface of the material will be enlarged greatly.In the hot airflow 95% - 98% of water can be evaporated instantly.time of completing the drying is several seconds.This is especially adapt to dry heating sensitive material.

4.Process of production is simple,it is an ideal choice for liquid material which contains 40%-90% of water and want to dry it to powder once,this type of machine can reduce the procedure of smash and sieve,the operational environment is superior,always clean,and under healthful condition,it also can avoid powder flying while drying.

Product Application

Chemical industry: battery raw materials, basic dyes and pigments, compound fertilizers, formaldehyde silicic acid, catalysts, sulfuric acid agents, amino acids, white carbon black, etc.

Plastic resin: AB, ABS emulsion, urea-formaldehyde resin, phenolic resin, sealant (urea) formaldehyde resin, polyethylene, polyvinyl chloride, etc.

Food industry: rich fat milk powder, protein, cocoa milk powder, milk substitute powder, animal blood meal, egg white (yellow) whole egg powder, etc.

Food and plants: oats, chicken juice, coffee, instant tea, spiced meat, protein, soybean, peanut protein, hydrolyzate, etc.

Sugars: corn syrup, corn starch, glucose, pectin, maltose, potassium sorbate, etc.

Ceramics: alumina, ceramic tile materials, magnesium oxide, talcum powder, etc.

Egg powder

Whey powder

Alumina powder

FAQ

Q: What information do I need to provide in order to obtain a professional and detailed quotation?

A: 1. What are your raw materials?

2. What is the initial moisture content and final moisture content of the raw materials?

3. How much did you ask for?

4. What heat source do you use?

Q: What is the lead time?

A:30-45 working day.

Q: How is the product packaged and delivered?

A: After the product is finished, it is packed in a fumigation-free wooden box and transported by sea or land.

Q: What standard models do you have? Does it support customized services?

A:We have the following standard models and support customized production.

Technical Parameters

|

Item丨Model

|

LPG-5

|

LPG-25

|

LPG-50

|

LPG-150

|

LPG-200-200

|

|||||

|

Inlet temp. ℃

|

140-350

|

|

|

|

|

|||||

|

Outlet temp. ℃

|

80-90

|

|

|

|

|

|||||

|

Max. water evaporation kg/h

|

5

|

25

|

50

|

150

|

200-2000

|

|||||

|

Tran

smission f

orm of

centrifugal atomizer

|

Compressed air transmission

|

Mechanical transmission

|

|

|

|

|||||

|

Maximum speed (r.p.m)

|

25000

|

18000

|

|

15000

|

8000-15000

|

|||||

|

Diameter of atomizer (mm)

|

50

|

120

|

|

150

|

180-240

|

|||||

|

Heat source

|

Electricity

|

Electricity, steam, natural gas, LPG

|

|

|

|

|||||

|

Max. power of electric heater (kw)

|

9

|

36

|

72

|

99

|

|

|||||

|

Overall dimensions (LWH) (m)

|

1.8*0.93*2.2

|

3*2.7*4.26

|

3.5*3.5*4.8

|

5.5*4*7

|

|

|||||

|

Dry powder recovery rate (%)

|

≥95%

|

|

|

|

|

|||||

|

Note: The amount of water evaporation is related to the characteristics of the material and the temperature of the hot inlet and outlet.

|

|

|

|

|

|

|||||

Packing & Shipping

Hot Searches