- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Adc12

-

Surface treatment:

-

Powder Coating

-

Application:

-

Communications industry

-

Product name:

-

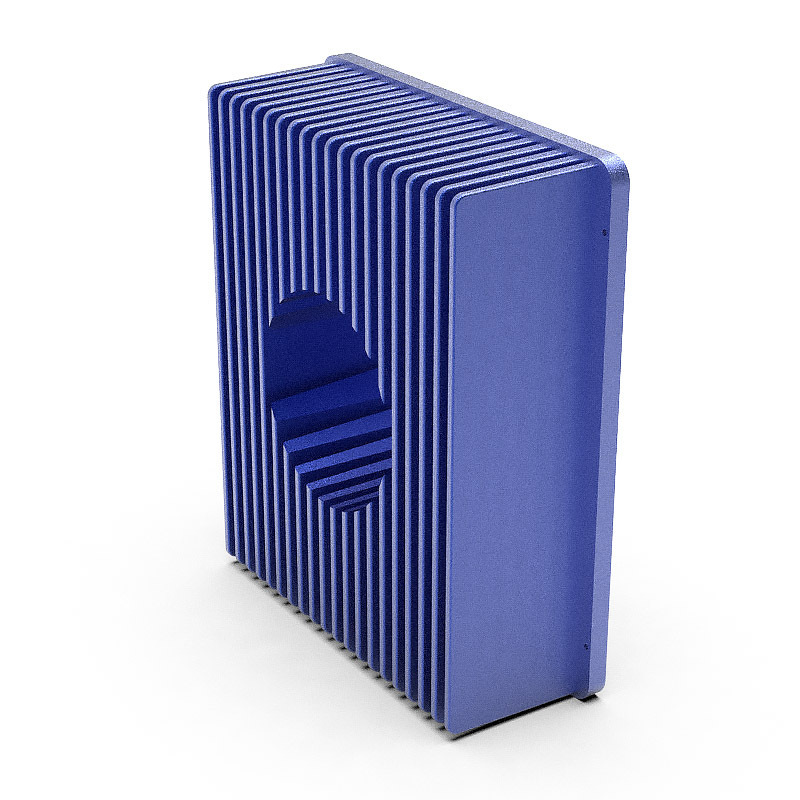

Custom aluminum waterproof enclosure

-

Process:

-

Casting +Machining(if Need)+surface Treatment

-

Service:

-

OEM Serivice

-

Color:

-

Customers' Required

-

Size:

-

Customer's 3D Drawing

-

MOQ:

-

100 Piece

-

Lead Time:

-

30-35days

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Chengdacai

-

Model Number:

-

2023050502

-

Material:

-

Adc12

-

Surface treatment:

-

Powder Coating

-

Application:

-

Communications industry

-

Product name:

-

Custom aluminum waterproof enclosure

-

Process:

-

Casting +Machining(if Need)+surface Treatment

-

Service:

-

OEM Serivice

-

Color:

-

Customers' Required

-

Size:

-

Customer's 3D Drawing

-

MOQ:

-

100 Piece

-

Lead Time:

-

30-35days

Company Introduction

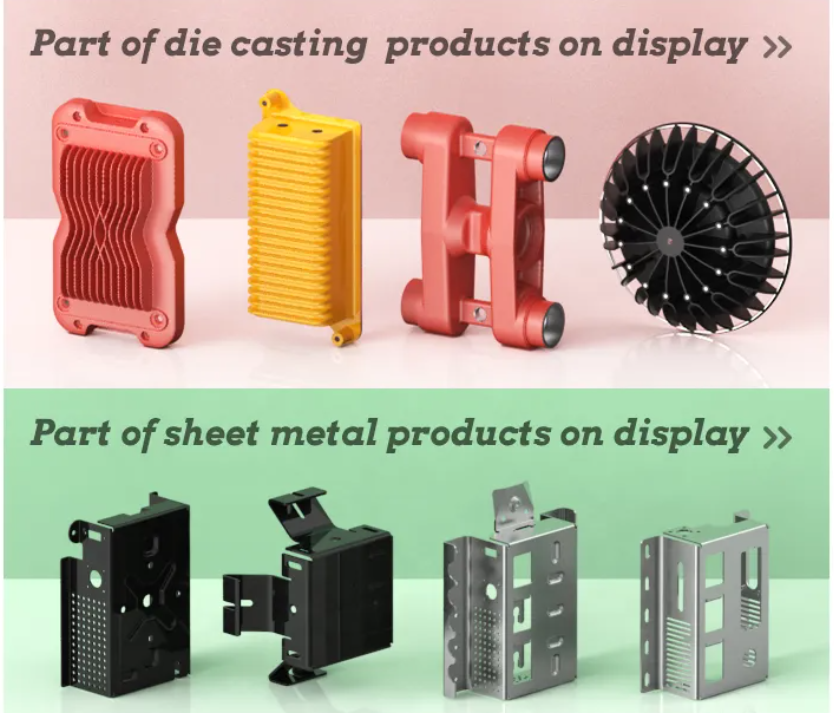

Our Workshop

Factory introduction

Our factory have multiple manufacturing capability and specialized in providing customized service for

CNC machining

parts

,

die-casting

Aluminum parts

,

aluminum extrusion parts

,

stamping metal parts

,

bending and laser cutting parts etc.

We have all kinds of machines,

such as die casting machine, CNC milling machine, large CNC punching machine, CNC lathe, drilling machine, wire cutting machine, laser cutting machine, water mill, welding machine, spark machine, and various auxiliary processing equipments

.

We have over

300

staffs fully functional in all departments, to ensure that every detail of all orders is well followed up from production to dispatch.

The most important is that we an excellent technical engineer team who have rich experience in providing professional design support and solution for our customer. They are including professional product designers, experienced mold makers, various professional machine tool divisions, and die casting and stamping professional technicians.

Our Service

Design Team

We have an engineering team of 10 persons, the director of our engineering team has more than 10 years of technical experience in the industry, specializing in process manufacturing and design of die casting parts, sheet metal parts, extrusion profile parts and CNC machining parts.

We can provide custom machining services and design optimization solutions for related parts to make the product structure better and manufacturing cost cheaper.

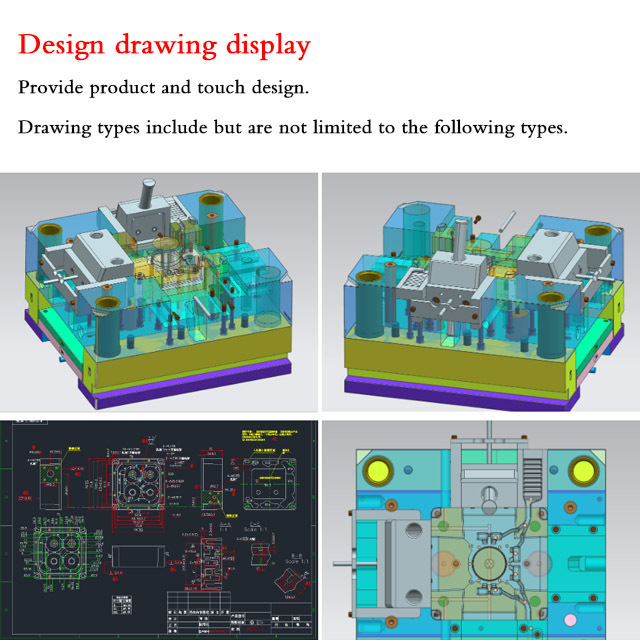

Design drawing display

Provide product and touch design.

Drawing types include but are not limited to the following types.

Certifications

Details Images

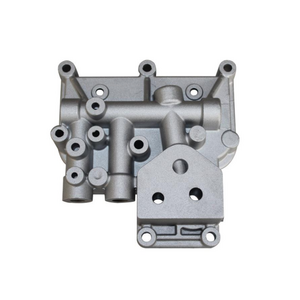

For some product displays, we can make including but not limited to the following products

. We can manufacture non-standard parts according to your drawing or sample.

Customer Review

Products Description

|

Brand

|

CHENGDACAI

|

|

Product name

|

Chengdacai OEM verified custom aluminum die casting enclosure service new energy vehicle battery cover die casting

|

|

Size

|

Customized size

|

|

Color

|

White, black,silver, red, grey, Pantone and RAL, etc

|

|

Material

|

Aluminum alloy ADC12, ADC10, A360, A380, A356, Zinc alloy ZA3#,ZA5#,ZA8#

|

|

Processing

|

Drawings→ mould making → die casting →rough machining → CNC machining →surface treatment →product checking→ packing →delivery

|

|

Surface treatment included

|

Electroplating, Chrome Plating, Zinc Plating, Nickel plating, Electrophoresis, Anodization, Polishing, Powder coating,

Sandblasting, Passivation, Spray painting, Etc. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Software

|

Pro/E, Auto CAD, CAXA UG, CAD

|

|

Service

|

OEM service available

|

|

Inspection

|

1.Foundry in-house: 100% inspection on critical dimension; 100% on appearance.

|

|

|

2.Third Party inspection available upon requirement

|

|

Mainly Testing Facility

|

Three-dimensional measuring instrument, Salt spray test box, Dynamic balance detector, Pneumatic detection

|

|

Payment

|

T/T,L/C

|

FAQ

Q1. How to keep your product quality?

Quality is our lives, we have technical worker and quality department to check all material and every step from the very beginning to ensure the quality of our products.

Here is the working flow of our QC System:

1) Confirm all drawings with customer and confirm the best production method.

2) Check the raw material before coming into our warehouse.

3) Confirm the samples, reports of material and specs with customer.

4) Keep checking every production line, including each production process and the working condition of each machine.

5) 100% full inspection before packing them.

6) Check the package before delivery.

Q2. What payments term can you accept?

T/T, L/C, Alibaba Trade Assurance;

1> Mould : 30% prepaid, 40% after the mould finish, balance after sample approval.

2> Bulk Goods : 30% prepaid, balance T/T before shipment.

Q3. How to get a quotation?

1> Send us the drawings or original samples.

2> Specify the kinds of material and surface treatment.

3> We will come back to you within 24 hours with our professional suggestion & quotation.

Q4. What is the estimate lead time for the sample of die casting products?

Normally, it takes about 30 working days for the mold development & another 10 working days for making samples after getting your

deposit.

Q5. What is the estimate lead time for the sample of stamping products?

Normally, it takes about 20 working days for the mold development & another 10 -15 working days for making samples after getting

your deposit.

Q6. Why choose us?

1). We are a professional OEM manufacturer

2). OEM service offered

3). Competitive price and lead time

4). High quality products

Q7: Is it possible to know how is my product going on without visiting your company?

A: We will offer a detailed products schedule and send weekly reports with digital pictures and videos which show the machining

progress

Please feel free to inquire us about the products you demand.

We will offer you our best service. Thank you.

Here is the working flow of our QC System:

1) Confirm all drawings with customer and confirm the best production method.

2) Check the raw material before coming into our warehouse.

3) Confirm the samples, reports of material and specs with customer.

4) Keep checking every production line, including each production process and the working condition of each machine.

5) 100% full inspection before packing them.

6) Check the package before delivery.

Q2. What payments term can you accept?

T/T, L/C, Alibaba Trade Assurance;

1> Mould : 30% prepaid, 40% after the mould finish, balance after sample approval.

2> Bulk Goods : 30% prepaid, balance T/T before shipment.

Q3. How to get a quotation?

1> Send us the drawings or original samples.

2> Specify the kinds of material and surface treatment.

3> We will come back to you within 24 hours with our professional suggestion & quotation.

Q4. What is the estimate lead time for the sample of die casting products?

Normally, it takes about 30 working days for the mold development & another 10 working days for making samples after getting your

deposit.

Q5. What is the estimate lead time for the sample of stamping products?

Normally, it takes about 20 working days for the mold development & another 10 -15 working days for making samples after getting

your deposit.

Q6. Why choose us?

1). We are a professional OEM manufacturer

2). OEM service offered

3). Competitive price and lead time

4). High quality products

Q7: Is it possible to know how is my product going on without visiting your company?

A: We will offer a detailed products schedule and send weekly reports with digital pictures and videos which show the machining

progress

Please feel free to inquire us about the products you demand.

We will offer you our best service. Thank you.

Hot Searches