- Product Details

- {{item.text}}

Quick Details

-

Productivity:

-

200m3/hr

-

Weight (KG):

-

138 kg

-

Material for housing:

-

stainess steel304/316

-

power supply:

-

AC110-240V,50/60Hz,1phase

-

max working pressure:

-

0.6Mpa,1.0Mpa

-

water temperature:

-

1--- 60 centigrade

-

PH value of water:

-

6.5---9.5

-

feed water turbidity:

-

3-6NTU

-

Feature:

-

Eco-Friendly Easy Operation

-

After-sales Service Provided:

-

Video Technical Support

-

UV lamp model:

-

25W,40W,80W,120W,150W,320W

-

Accessories:

-

UV lamps,glass tube,ballasts

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

YLD

-

Material:

-

plywood case

-

Productivity:

-

200m3/hr

-

Weight (KG):

-

138 kg

-

Material for housing:

-

stainess steel304/316

-

power supply:

-

AC110-240V,50/60Hz,1phase

-

max working pressure:

-

0.6Mpa,1.0Mpa

-

water temperature:

-

1--- 60 centigrade

-

PH value of water:

-

6.5---9.5

-

feed water turbidity:

-

3-6NTU

-

Feature:

-

Eco-Friendly Easy Operation

-

After-sales Service Provided:

-

Video Technical Support

-

UV lamp model:

-

25W,40W,80W,120W,150W,320W

-

Accessories:

-

UV lamps,glass tube,ballasts

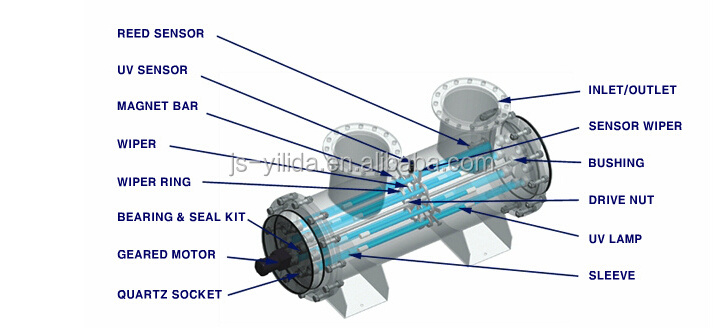

UV Sterilizers

Ultraviolet water treatment systems (UV sterilizers) kill bacteria in water. They are often used to ensure safe drinking water from well, spring and borehole water supplies. Due to increased legislation are now regularly used in food and drink related industries.

Micro organisms including bacteria, viruses and cysts are all around us naturally. Many are harmless but exposure to "bad" ones can cause severe illness particularly in the elderly and very young. There is a wide variety of water treatment products available to improve taste, clarity, scale etc but none of these are designed to combat bacteria. Ultra violet water treatment is one of the safest ways to disinfect water as the UV rays are a natural component of sunlight. No chemicals are added so there is no danger from overdosing or creating a bad taste.

A UV sterilizer works in harmony with other essential filters by eliminating nuisance green water caused by waterborne algae that can easily create problems and ultimately reduce filter efficiency.

Protecting your Aquarium Fish.

For almost three decades UV sterilization has proven itself as an alternative to harsh copper sulfate chemical treatments to control waterborne pathogens and algae.

The Truth about UV!

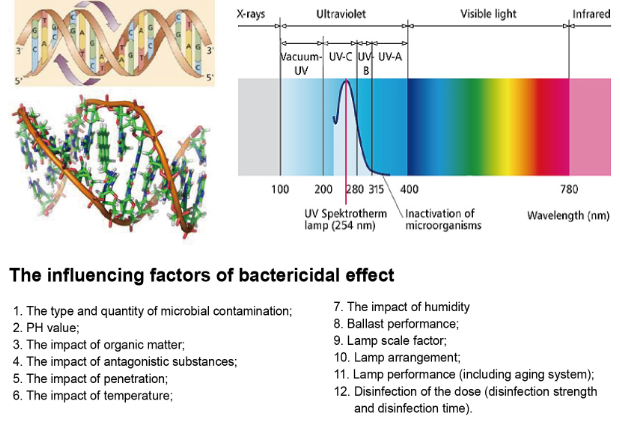

Regardless of whether you choose to label UV as a water clarifier or a water sterilizer, the same design, performance, and operating principals apply. Successful UV operation means destroying the targeted microorganisms. Here are five main factors that will help determine the ability of a UV sterilizer (or clarifier) to achieve this desired effect.

1.

What Type of Lamp?

There are two types of UV-lamps available: low-pressure or medium/high-pressure. As explained below, low-pressure lamps are much better in aquatic sterilizers.

2. The Length of the Lamp ...

being used; also known as ARC length.

3. The Physical Design ...

of the UV's water exposure chamber. The distance the UV has to travel from the surface of the lamp to the inner wall of the UV's water containment vessel is the primary design criteria that will determine the unit's "UV dose rate" at any given water flow rate.

4. The Condition of the Water ...

to be treated. The term used to express the ability of a body of water to be effectively treated by a UV light source is known as percent transmittance. This is a value expressed in percent, which is used to indicate the quality of the water to be treated. The higher the percent transmittance the higher the effectiveness of the UV sterilizer in treating the water.

5. Water Flow Rate ...

through the UV's contact chamber. The amount of water that is passed through the UV filter will ultimately determine the unit's actual UV dose rate, which is expressed in microwatts per second per square centimeter or (u-watts-sec/cm2).

Application

1.Food processing industry, including juices, milk, drinks, beer, practical oil and canned food.

2.Electronic industry.

3.Hospitals, various laboratory and high levels of pathogenic body water disinfection.

4.Households building, residential, office buildings, hotels, restaurants, water factories.

5.Purification and disinfection of shellfish, fish cleaning and disinfection

6.Military camp, field water supply system

7.Urban wastewater disinfection.

8.Swimming pool, other recreational water disinfection

9.Thermal power, nuclear power plant industrial, central air conditioning system cooling water.

10.Biological, chemical and pharmaceutical, cosmetics for the production of cooling water.

11.Sea water, fresh water breeding, aquaculture water

12.Agricultural water disinfection

Principle of Operation

UV water disinfection system design has been carefully conceived to provide adequate germicidal dosage throughout the disinfection chamber. The dosage, as it applies to UV disinfection, is a function of time and the intensity of UV radiation to which the water is exposed. Exposure time is related to the flow rate, the higher the flow rate, the lower the exposure time or the lower the flow rate, the higher the exposure time. The UV intensity is the amount of energy, per unit time, emitted by germicidal lamp. The Dosage is the product of UV intensity and the exposure time.

Limitation of Use

The UV water disinfection system NOT intended for the treatment of water that has an obvious contamination or intentional source, such as raw sewage, nor is the unit intended to convert wastewater to microbiologically safe drinking water.

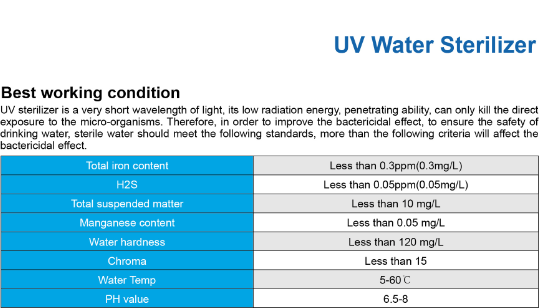

Water Quality (in)

Water quality plays a major role in the transmission of germicidal UV rays. It is recommended that the water does not exceed following maximum concentration levels

Maximum Concentration Levels ( Very Important )

|

Iron |

≤0.3ppm(0.3mg/L) |

|

Hardness |

≤7gpg(120mg/L) |

|

Turbidity |

≤1NTU |

|

Manganese |

≤0.05ppm(0.05mg/L) |

|

Tannins |

≤0.1ppm(0.3mg/L) |

|

UV Transmittance |

≥750‰ |

Effectively treating water with higher concentration levels than listed above can be accomplished, but may require added measures to improve water quality to treatable levels. If, for any reason, it is believed the UV transmission is not satisfactory, contact the factory.

UV wavelength (nm)

|

DOSAGE is the product of intensity & time dosage=intensity*time=micro watt/cm 2 *time=microwatt-seconds per square centimeter (μW-s/cm 2 ) Note :1000μW-s/cm 2 =1mj/cm 2 (milli-joule/cm 2 ) |

As a general guideline, the following are some typical UV transmission rates (UVT)

|

City water supplies |

850-980‰ |

|

De-ionized or Reverse Osmosis water |

950-980‰ |

|

Surface waters(lakes, rivers, etc) |

700-900‰ |

|

Ground water(wells) |

900-950‰ |

|

Other liquids |

10-990‰ |

parameter