- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

DL Sand molding machine

-

Voltage:

-

380V 50HZ

-

Power:

-

15 KW

-

Dimension(L*W*H):

-

4150*1890*3050 mm

-

Type:

-

Automatic shell molding machines

-

The Size Of Sand Mold:

-

300 * 400 / 350 * 400 / 350 * 450 ( mm )

-

The Thickness Of Sand Mold:

-

( 80~150 ) * 2 ( mm )

-

The Speed Of Manufacturing Mold:

-

36-50 sec / mold

-

Compaction Pressure:

-

not more than ( 40 - 80 ) kg

-

Air Comsumption ( Normal / Mold):

-

0.3 cubic meter

-

Humidity Of Sand Mold:

-

2.8 % ~ 3.5 %

-

The Thickness Of Template:

-

20 ~ 25 mm

-

Drive Method:

-

Electric-Pneumatic-Hydraulic

-

Usage:

-

Foundry Pieces Production

-

Weight:

-

About 5T

-

Certification:

-

CE

Quick Details

-

Place of Origin:

-

Fujian, China

-

Machine Type:

-

Foundry molding machine

-

Marketing Type:

-

sand molding machine

-

Brand Name:

-

DL Sand molding machine

-

Voltage:

-

380V 50HZ

-

Power:

-

15 KW

-

Dimension(L*W*H):

-

4150*1890*3050 mm

-

Type:

-

Automatic shell molding machines

-

The Size Of Sand Mold:

-

300 * 400 / 350 * 400 / 350 * 450 ( mm )

-

The Thickness Of Sand Mold:

-

( 80~150 ) * 2 ( mm )

-

The Speed Of Manufacturing Mold:

-

36-50 sec / mold

-

Compaction Pressure:

-

not more than ( 40 - 80 ) kg

-

Air Comsumption ( Normal / Mold):

-

0.3 cubic meter

-

Humidity Of Sand Mold:

-

2.8 % ~ 3.5 %

-

The Thickness Of Template:

-

20 ~ 25 mm

-

Drive Method:

-

Electric-Pneumatic-Hydraulic

-

Usage:

-

Foundry Pieces Production

-

Weight:

-

About 5T

-

Certification:

-

CE

Main Specification And Technical Parameters

| Size Of Appearance Of Machine | 4150*1890*3050 mm |

| Weight | 5T |

| Size Of Sand Mold | 350*450mm/410*510mm/500*600mm/600*700mm |

| Compaction Pressure | not more than 10 Mpa |

| The Thickness Of Sand Mold | ( 80~150 ) * 2 ( mm ) |

| The Speed Of Manufacturing Mold | 36 sec / mold |

| Machine Total Power | 15 kw |

| Air Comsumption ( Normal / Mold) | 0.3 m³ |

| Drive Method | Electric-Pneumatic-Hydraulic |

| Power Supply | 380V 50Hz |

|

Humidity Of Sand Mold |

2.8 % ~ 3.5 % |

|

The Thickness Of Template |

20 ~ 25 mm |

* some parameters can be customised by client's requirement.

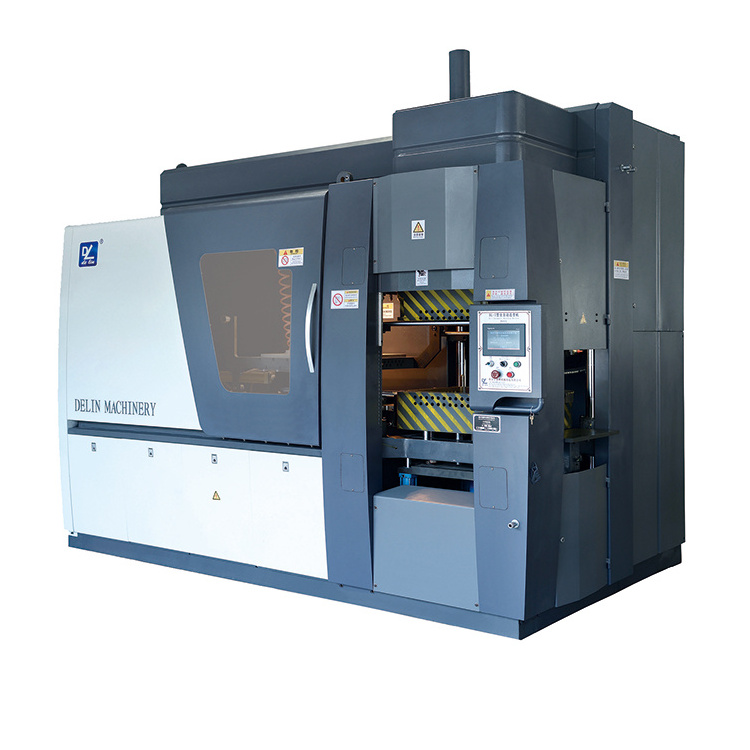

Automatic Sand Molding Machine

3. Highly standardized, good parts interchangeable, fast and low-cost maintenance

4. The sand could be compacted both inside and outside according to technical

requirements, which makes the sand mold better.

5. Mold release agent is sprayed automatically, which makes the demolding smoothly.

casting surface glossily, and no defect in the sand mold.

6. Electric cabinet and hydraulic station are all installed in the machine, which makes

them compact and easy maintenance.

7. Low failure rate, and the machine can diagnose the failure by its own.

Foundry Machine Assembly

Finished Machine Showing

Automatic Sand Molding Machine Working Process

a. The fist step is convey the sand to molding machine;

b. The second step is shooting the sand to the mould,and compacting up and down;

c. The third step is put the sand core in to the mould and compacting up and down,until be a forming die;

d. The fourth step is unloading the sand box;

e. Then molding placement;

f. Finally,pouring the iron water into to the sand mould.When it cold ,the mold is finish.

Some Finished Products Samples

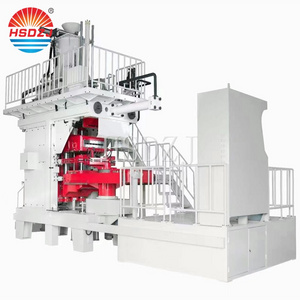

Automatic Casting Production Solutions

(more details please contact us as your free!)

After years research, Nan'an delin machinery company are combined with China’s small and medium foundry reality designed a variety of automated production line plan ,the maximum use of existing foundry equipment, tooling, sites, form a complete set of electric power, save a lot of investment for foundry, quick installation, commissioning and put into production , make your return on investment as soon as possible to get a bargain.

Flexible service form, we can provide from the sand processing, modeling casting cooling and pressure on the iron box automatically take on the old sand recycling and full turnkey engineering services , also you can adopt our company design. Except any part of the molding machine,client can choose by yourself. That's means our client's casting factory can make full use of their available resources so as to save investment, we will work to assist you.

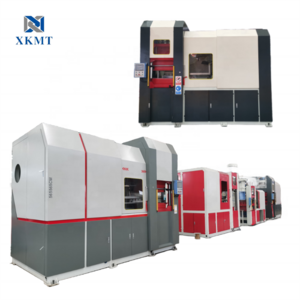

Other Type Hot Sale Sand Molding Machines