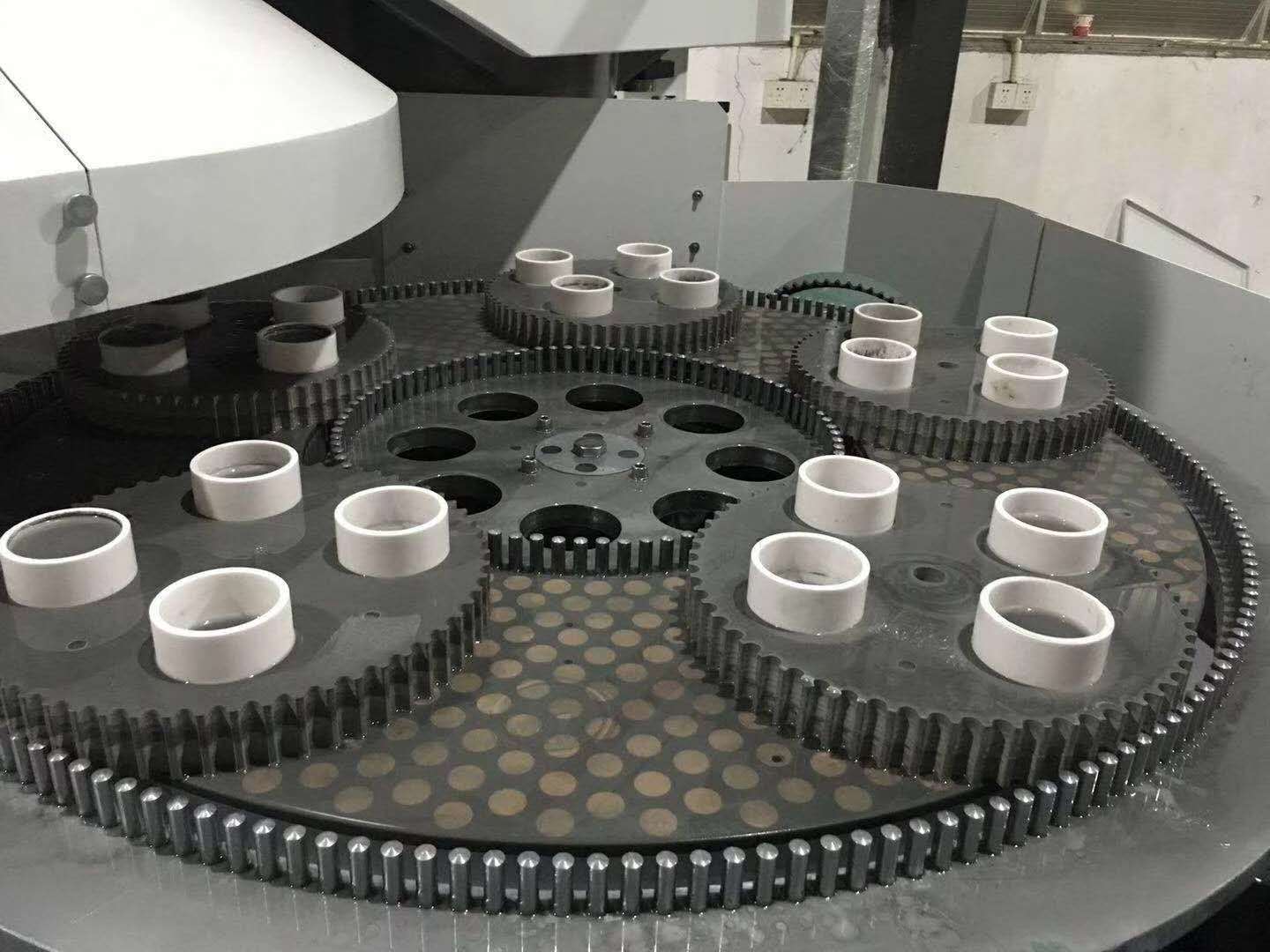

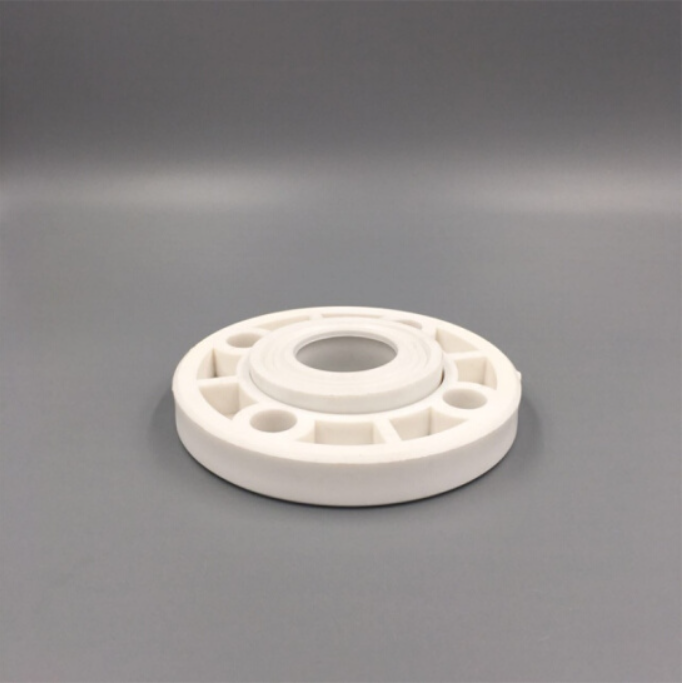

This machine is mainly suitable for grinding or polishing thin and brittle metals or non-metals such as silicon wafer, quartz wafer, optical crystal, glass, gemstone, lithium niobate, gallium arsenide, ceramic wafer, etc.

This series of grinding machine is a precision grinding machine, the upper and lower grinding discs rotate in opposite directions,and the work piece is rotating in the carrier with both rotation and rotation. The grinding resistance is low and the work piece is not damaged, and the grinding is even on both sides, which makes the production efficiency high.

- Product Details

- {{item.text}}

Quick Details

-

Year:

-

2021

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BOBO

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1350*950*2200mm

-

Weight (KG):

-

1980

-

Power (kW):

-

3.7

-

Product name:

-

Grinding Polishing Disc Ceramic Parts Machine In Machining

-

Usage:

-

Surface Grinding

-

Keywords:

-

CNC Grinder

-

Color:

-

White

-

Advantage:

-

Saving Energy

-

Function:

-

Processing Parts

-

Key words:

-

Precision Grinding Polishing

-

Suitable for:

-

Grinding Surface

-

After-sales Service Provided:

-

Free spare parts, Online support, Field maintenance and repair service, Video technical support, Field installation, commissioning and training

-

After Warranty Service:

-

Video technical support, Field maintenance and repair service, Spare parts, Online support

-

Local Service Location:

-

None

-

Certification:

-

CE

Quick Details

-

Grinding Length(mm):

-

1200

-

Surface Roughness(μm):

-

0.2 μm

-

Table Size(mm):

-

622*218*30

-

Year:

-

2021

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BOBO

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1350*950*2200mm

-

Weight (KG):

-

1980

-

Power (kW):

-

3.7

-

Product name:

-

Grinding Polishing Disc Ceramic Parts Machine In Machining

-

Usage:

-

Surface Grinding

-

Keywords:

-

CNC Grinder

-

Color:

-

White

-

Advantage:

-

Saving Energy

-

Function:

-

Processing Parts

-

Key words:

-

Precision Grinding Polishing

-

Suitable for:

-

Grinding Surface

-

After-sales Service Provided:

-

Free spare parts, Online support, Field maintenance and repair service, Video technical support, Field installation, commissioning and training

-

After Warranty Service:

-

Video technical support, Field maintenance and repair service, Spare parts, Online support

-

Local Service Location:

-

None

-

Certification:

-

CE

Product Description

Grinding Polishing Disc Ceramic Parts Machine In Machining

Features of machine

1、Using AC frequency conversion motor drive, soft start and soft stop, smooth and reliable.

2、Hydraulic lifting gear ring, very smooth, with shims under the sun wheel to adjust the position, effectively using the gear ring and sun wheel.

3、The upper plate is separately set up with slow descending cylinder, which not only effectively prevents the breaking of thin and brittle workpieces, but also allows independent pressure control.

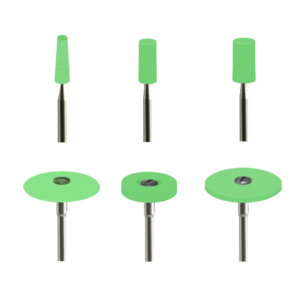

4、By using electronic preset counter, the number of grinding turns and requirements can be accurately controlled. 5、The grinding disc can be trimmed by using the trimming disc.

Specification

|

Diameter of grinding disc(mm)

|

φ622×φ218×25(upper disc)φ622×φ218×30(lower disc)

|

|

Maximum ideal grinding diameter(mm)

|

φ180

|

|

Flatness of processed parts

|

0.2μ(φ10)

|

|

Roller parameter

|

Inch DP12, Z=108

|

|

Minimum grinding thickness

|

0.3mm(φ10mm)

|

|

Power of main machine

|

3.7KW

|

|

Rotating speed of lower grinding disc(rpm)

|

0~60rpm

|

|

Sand pump power

|

120W

|

|

Sand flow form

|

circulation or drip

|

|

Equipment size(mm)

|

1350X950X2200mm

|

|

Weight(KG)

|

1980

|

Packing and Shipping

Packaging:

Stable wooden package protects machine from strike and damage.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

Shipping:

For LCL, we cooperated with reputable logistics team to send machine to sea port speedily and safely.

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like to have seamless cooperation with your forwarder at your convenience.

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like to have seamless cooperation with your forwarder at your convenience.

About Us

FAQ

1. Q: What is the power supply of the machine?

A: The standard power supply in china is 380V, 3P, 50Hz. We also can customized accordingly.

2. Q: What information should the customer provide to get an accurate quotation from us?

A: The customer should provide the related technical requirements, drawings, pictures, industrial voltage, planned output, etc

3. Q: What is the payment term A: The payment term is 30% down payment, and 70% before shipment(T/T mode), we also accept other payment term, like L/C, DA, D/P etc

4. Q: What is the delivery time?

A: Normally the delivery time of the machine is 30 days after receive down payment.

5. Q: What is the warrantee period of the machine?

A: The warrantee period is one year since the date of B/L.

A: The standard power supply in china is 380V, 3P, 50Hz. We also can customized accordingly.

2. Q: What information should the customer provide to get an accurate quotation from us?

A: The customer should provide the related technical requirements, drawings, pictures, industrial voltage, planned output, etc

3. Q: What is the payment term A: The payment term is 30% down payment, and 70% before shipment(T/T mode), we also accept other payment term, like L/C, DA, D/P etc

4. Q: What is the delivery time?

A: Normally the delivery time of the machine is 30 days after receive down payment.

5. Q: What is the warrantee period of the machine?

A: The warrantee period is one year since the date of B/L.

Hot Searches