- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

30-90kw

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

5000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Model:

-

DxH:1200*1400MM D1400*H1600MM D1800*H2000MM

-

Coating technology:

-

vacuum evaporation coating

-

Coating color:

-

silver, golden, red, blue, green, rainbow etc.

-

Coating material:

-

ABS, PP, acrylic plastic products, glass, ceramic,alloy

-

Control mode:

-

PLC touch screen automatic control

-

Application:

-

cosmetic caps, shoe heel plastic, glass, ceramic tiles, crystal etc.

Quick Details

-

Machine Type:

-

pvd vacuum coating machine, Coating Equipment

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HCVAC

-

Voltage:

-

380V

-

Power:

-

30-90kw

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

5000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Model:

-

DxH:1200*1400MM D1400*H1600MM D1800*H2000MM

-

Coating technology:

-

vacuum evaporation coating

-

Coating color:

-

silver, golden, red, blue, green, rainbow etc.

-

Coating material:

-

ABS, PP, acrylic plastic products, glass, ceramic,alloy

-

Control mode:

-

PLC touch screen automatic control

-

Application:

-

cosmetic caps, shoe heel plastic, glass, ceramic tiles, crystal etc.

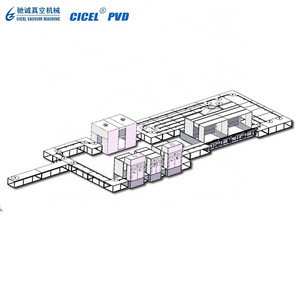

Plastic Vacuum Metallizing Machine,plastic Magnetron sputtering coating machine,automatic UV painting and drying line

| DETAILED DESCRIPTION |

| What we can do |

1. Turnkey project of dustfree gun-fixed Automatic UV Coating Line + Vacuum Coating Chamber Plant for plastic parts

2. Turnkey dustfree robot automatic UV spray coating line

3. Turnkey dustfree reciprocator automatic spray coating line

4. Turnkey dustfree automatic/manual spray coating plant (UV line / PU line)

5. Air make-up unit / air handling unit

6. Centralized thermostat air conditioning system

7. Clean class (10,000-100,000 class)

8. IR curing oven / convection oven

9. UV curing oven

10. Various conveyor system

Vacuum Metallizing&Sputtering Coating Machine + UV Coating Plant

1.Vacuum coating chamber

2.Vacuum coating plant+UV coating plant

3.Pvd Sputtering coating machine

4.SS vacuum coating chamber body

5.Conveyorised automatic vacuum coating UV coating plant

6.dustfree automatic UV coating plant: clean class 10,000-100,000

| Process flow |

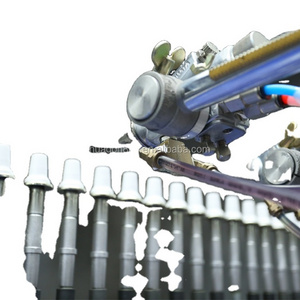

1) Base painting: Load products on line-electrostatic cleaning-PP paints sraying (for PP material)--IR oven--base painting--IR leaveling preheating--UV curing--cooling--off-line

2) Vacuum coating/metallizing/Sputtering : load products in HCRE series evaporation vacuum coating machine-metallizing/sputtering-unload products

3) Top painting : load products on UV line—electrostatic cleaning—top painting—IR leveling preheating—UV curing—cooling—unload products (made-up articles)

| Application |

|

Applied industry: Widely used in Cosmetic caps/bottles, mobile phone covers, shoe heels, automotive, audio and varinous small appliances, computers, clocks and watches, toys cell phones reflective Cup, tableware sanitary industries etc. It's sutiable for ABS, PS, PP, PC, PVC, PET, nylon,metal, Boli, glass, ceramics, TPU material etc.

Metallizing effects: general electroplating-face, dumb-(semi-mute, all dumb), the metallizing process wrinkles, wiredrawing,raindrop ect.

Coating color: gold, silver, red, blue, green, purple,rainbow color etc.

| Mode | HCRE-1214 | HCRE-1416 | HCRE-1618 | HCRE-1820 |

| Dimension (D*H) | 1200*1400mm | 1400*1600mm | 1600*1800mm | 1800*2000mm |

| Film type | Semitransparent film, non-conducting film, gold, silver, red, blue, green, purple, seven color, etc | |||

| Power source | Thermal evaporation power, ion bombard power, RF power | |||

| Vacuum chamber structure | Vertical double/single door, horizontal single door, pump system postposition | |||

| Ultimate vacuum | 8.0*10 -4 Pa | |||

| Vacuum system | Diffusion pump +Roots pump +Mechanical pump +Holding pump | |||

| Pump time | Pump from atmosphere to 5.0*10 -2 , <= 6 minutes | |||

| Workpiece motion mode | Public rotation/ Frequency control | |||

| Control mode | Manual/Automatic all in one mode, Touch screen + PLC | |||

| Remark | We can design the dimension of the equipment according to customer’s special technique requirement. | |||

| MACHINE PHOTOS |

| SAMPLE PHOTOS |

|