- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

UNIPRETEC

-

Color:

-

black, grey, white, ivory

-

Max. Working Temp.:

-

600 - 1,800 °C

-

Electrical Insulation:

-

Excellent

Quick Details

-

Material:

-

Technical Ceramics

-

Place of Origin:

-

Fujian, China

-

Model Number:

-

customized

-

Brand Name:

-

UNIPRETEC

-

Color:

-

black, grey, white, ivory

-

Max. Working Temp.:

-

600 - 1,800 °C

-

Electrical Insulation:

-

Excellent

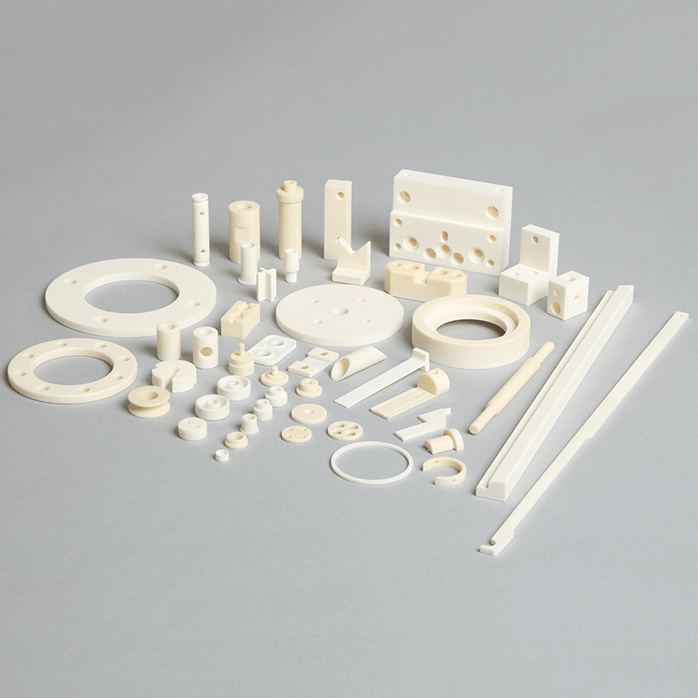

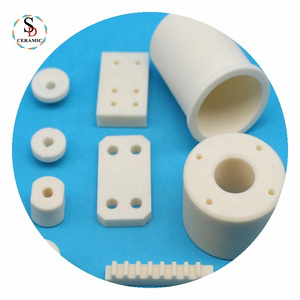

Product Features

● High Use Temperature

●

●

Low CTE

●

●

Thermal Conductive

●

● High Hardness

●

● High Mechanical Strengh ●

●

Corrosion Resistant

●

●

Electrical Insulation

●

●

Resistant to Heat Shock

●

● Flexible Custom Production ●

Description

Advanced technical ceramics have the advantages of metal and other materials that do not have. With the development of science and technology, especially the development of energy and space technology, materials need to be used in relatively harsh conditions. The development of space technology (such as spacecraft nozzles, combustion chamber linings, jet engine blades, etc.) puts forward higher and higher requirements for materials. Reactors, heat exchangers, and nuclear fuels in petrochemicals, energy development, etc. require materials with high temperature resistance, corrosion resistance, and wear resistance to become increasingly stringent. It can be seen that advanced ceramics are becoming more and more important, and the demand for its varieties is increasing day by day.

|

● Alumina (Al2O3)

|

● Machinable Glass Ceramic

|

|

● Aluminum Nitride (AlN)

|

● Silicon Carbide (SSiC & SiSiC)

|

|

● Boron Carbide (B4C)

|

● Silicon Nitride (Si3N4)

|

|

● Boron Nitride (Hex BN)

|

● Zirconia (ZrO2)

|

Applications

Products made of industrial ceramics have a wide range of uses. With its high mechanical strength and high insulation resistance, it can be used as vacuum devices, device porcelain, thick film and thin film circuit substrates, thyristor and solid circuit shells, spark plug insulators, etc. With its high strength and hardness, it can be used as abrasives, textile ceramics, knives, etc. With its chemically stable and better performance, it can be used as chemical and biological ceramics, artificial joints, replacement of platinum crucibles, catalytic carriers, and aviation and magnetic fluid power generation materials. With the development of science and technology and the improvement of manufacturing technology, new varieties of high temperature engineering ceramics continue to appear, which will be more and more widely used in modern industry and modern science.

Material Properties

|

ITEM

|

UNIT

|

Alumina

A950

|

Alumina

A990

|

Silicon Niride

GPSN

|

Zirconia

YSZ95

|

|

Main Content

|

-

|

95% Al2O3

|

99% Al2O3

|

Si3N4 > 90%

|

ZrO2 > 94.5%

|

|

Color

|

-

|

White / Pink

|

Ivory

|

Black

|

White, Black

|

|

Density

|

g/cm

3

|

3.7

|

3.85

|

3.22

|

5.95

|

|

Vickers Hardness

|

Gpa

|

14

|

17

|

15

|

12

|

|

Flexural Strength

|

Mpa

|

310

|

360

|

580

|

800

|

|

Compressive Strength

|

Mpa

|

2,200

|

2,500

|

2,200

|

2,500

|

|

Electrical Resistivity

|

Ω·cm

|

>10

14

|

>10

14

|

>10

12

|

>10

10

|

|

Dielectric Strength

|

KV/mm

|

15

|

17

|

19

|

9

|

|

Dielectric Constant

|

1 MHz

|

8

|

9

|

9.6

|

28

|

|

Thermal Conductivity

|

W/m.K

|

25

|

29

|

27

|

2.2

|

|

Max. Working Temperature

|

℃ / °F

|

1,500 / 2,730

|

1,650 / 3,000

|

1,200 / 2,190

|

800 / 1,470

|

|

Resistance to Thermal Shock

|

△T(℃)

|

210

|

230

|

750

|

260

|

|

CTE (25 - 1,000 ℃)

|

10

-6

/K

|

7 - 9

|

7 - 9

|

3 - 4

|

11 - 13

|

∆ The above data is offered for reference and comparison only, exact data will vary depending on manufacturing method and part configuration.

Inspection

About Us

"Simple things into very complex, can find new areas; Read the complex phenomenon is very simple, can be found that the new law." - - - - - -Isaac Newton

Hot Searches