- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1820x1970X3200mm

-

Model Number:

-

JH25-110

-

Weight (T):

-

14

-

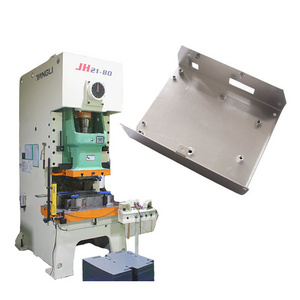

160ton c frame double crank power press:

-

progressive press

-

Pressure Capacity:

-

110ton

-

Application:

-

Metal Sheet Stamping

-

clutch:

-

wet clutch

-

overload protected system:

-

hydraulic overload pump

-

Control System:

-

PLC(Touch Screen)

-

lubrication system:

-

auto grease pump

-

slide guide:

-

6 faces

-

Weight:

-

14000kg

-

Power:

-

11KW

Quick Details

-

Slide Stroke (mm):

-

110

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

WORLD

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1820x1970X3200mm

-

Model Number:

-

JH25-110

-

Weight (T):

-

14

-

160ton c frame double crank power press:

-

progressive press

-

Pressure Capacity:

-

110ton

-

Application:

-

Metal Sheet Stamping

-

clutch:

-

wet clutch

-

overload protected system:

-

hydraulic overload pump

-

Control System:

-

PLC(Touch Screen)

-

lubrication system:

-

auto grease pump

-

slide guide:

-

6 faces

-

Weight:

-

14000kg

-

Power:

-

11KW

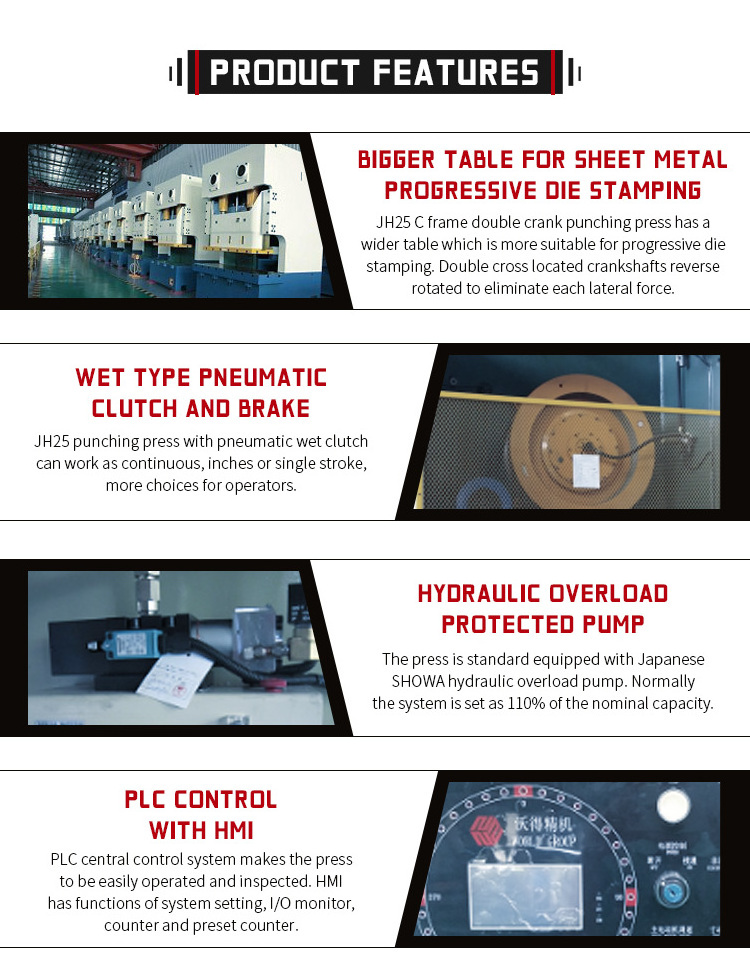

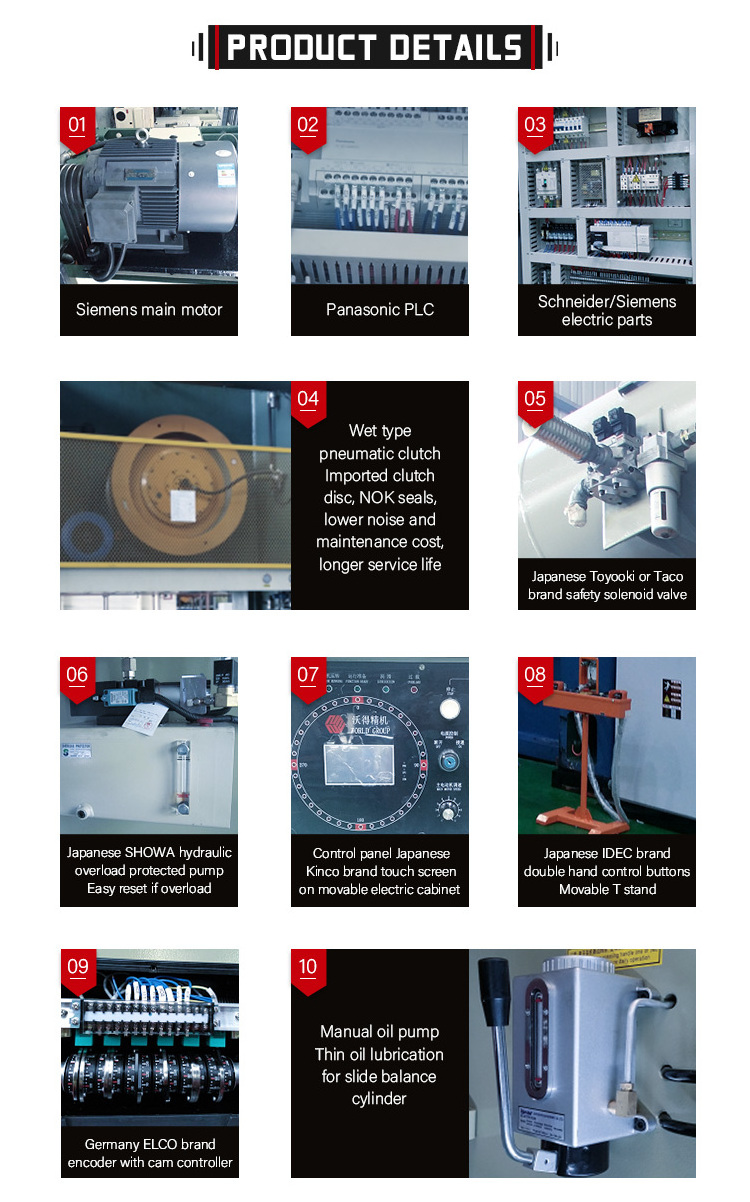

1. Bigger size table and slide

The bigger size table and slide is better for big size sheet metal blanking, stamping and piercing. And the press can equip with progressive die to improve production efficiency.

2. PLC control

The press adopts Panasonic or Omron PLC with high stability and longer service life.

3. High torque low noise wet clutch

World produce the wet clutch. We use the best seals, bearing and friction discs. The wet cultch features lower noise and longer service life.

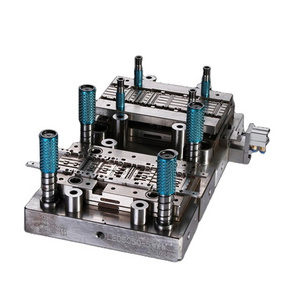

4. Six faces rectangular guide rail

The presses use a slide with six faces rectangular guide rails to ensure better punching accuracy.

5. Hydraulic overload protected

Hydraulic overload protected pump is used to protect the press and the die if the machine is overloaded. You can reset the overload with the switch on the touch screen easily.

6. Easy control

The touch screen includes the counter, crankshaft angle displayer, control switches and alarm lights. You can set the press with the touch screen and any defaults of the press can be checked with it.

7. Auto lubrication system

The press is equipped with auto lubrication pump and it is easy for maintenance. You can set the lubrication circle time by the touch screen.