- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V 50HZ

-

Power:

-

116KW

-

Dimension(L*W*H):

-

According to the practice

-

Weight:

-

4500 kg

-

Marketing Type:

-

Hot Product 2023

-

Raw material:

-

Waste paper

-

Final product:

-

Egg Tray, Egg Carton, Paper tray

-

Time of delivery:

-

40 days

-

Tray mould:

-

customized (aluminum,copper,plastic)

-

After-sales Service:

-

Engineers available to service machinery overseas

-

Color:

-

Customized

-

Capacity:

-

1000-6000PCS/HOUR

-

After Warranty Service:

-

Free spare parts, Online support, Video technical support

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Certification:

-

CE

Quick Details

-

Production Capacity:

-

1000-6000pieces/ hour

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Shunfu

-

Voltage:

-

380V 50HZ

-

Power:

-

116KW

-

Dimension(L*W*H):

-

According to the practice

-

Weight:

-

4500 kg

-

Marketing Type:

-

Hot Product 2023

-

Raw material:

-

Waste paper

-

Final product:

-

Egg Tray, Egg Carton, Paper tray

-

Time of delivery:

-

40 days

-

Tray mould:

-

customized (aluminum,copper,plastic)

-

After-sales Service:

-

Engineers available to service machinery overseas

-

Color:

-

Customized

-

Capacity:

-

1000-6000PCS/HOUR

-

After Warranty Service:

-

Free spare parts, Online support, Video technical support

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Certification:

-

CE

Cheap Price Paper Pulp Molding Drying Egg Tray Making Machine

Egg Tray Machine is the machine which can use all kinds of waste paper as the raw material to produce egg tray, egg box, egg carton, apple tray and other packing products etc. by changing different moulds. It has received good reputation for its good quality, high output, low energy-consuming and low maintenance.

The raw material use general waste paper, like old book, newspaper.carton books ,etc

All products can customized as your requests

Equipments of Egg Tray Machine

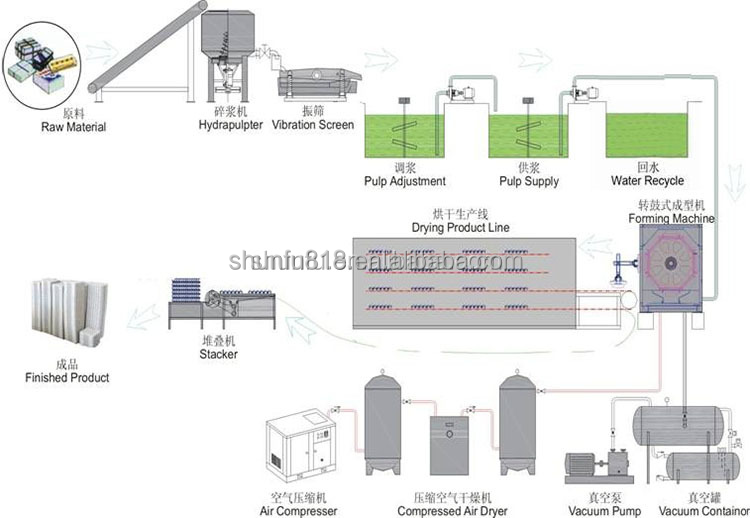

Egg Tray Machine Production Line Work Flow Chart

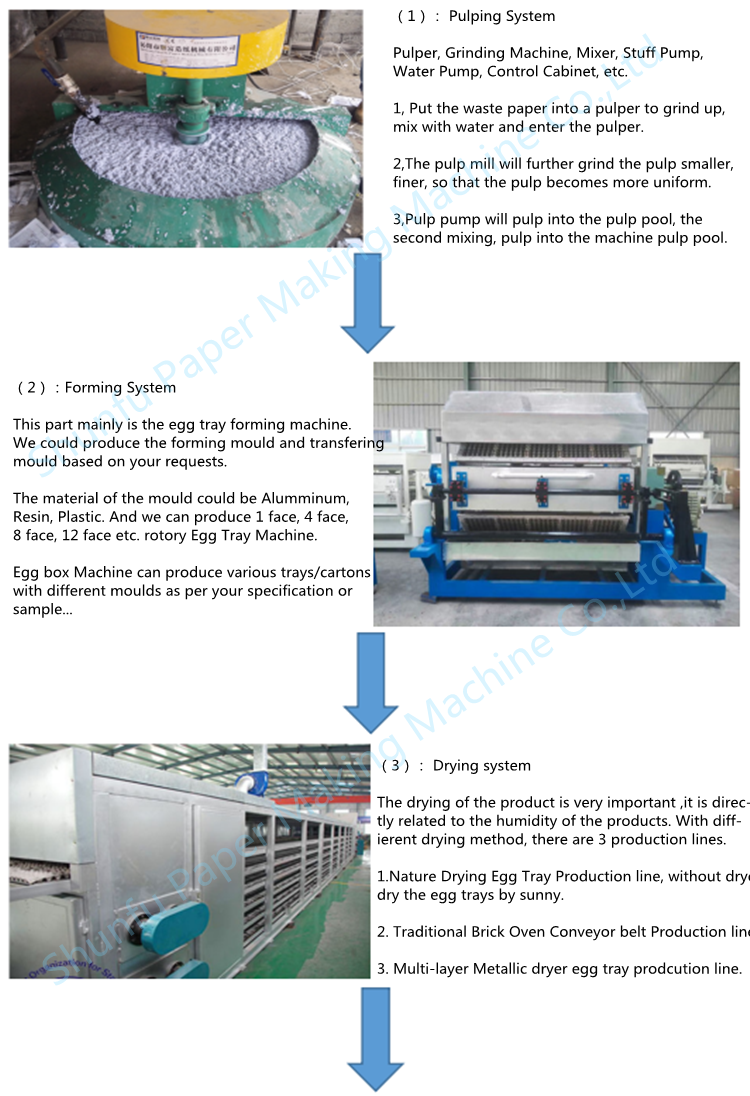

- 1. Pulping System

1) Put the raw material into the pulping machine and add the right amount of water after a long time stirring so that the waste paper into the pulp storage pool after storage.

2) The pulp in the slurry storage tank is put into the mixing tank, and the pulp concentration is adjusted in the mixing tank. The white water in the return tank and the concentrated pulp in the slurry storage tank are further stirred by the homogenizer. After being adjusted into suitable pulp, it is put into the pulp pool to be used in the molding system.

- 2. Forming System

1) The pulp in the pulp supply pool is fed into the molding machine, which is adsorbed by the vacuum system, and the pulp is left on the mold on the equipment to form. The white water is returned to the pool by the vacuum pump adsorption drive.

2) After the mold is adsorbed, the transfer mold is pumped out by the positive pressure of the air compressor, and the formed products are blown from the forming mold to the rotating mold, and then sent out by the transfer mold.

- 3. Drying System

1) Natural drying method: directly rely on the weather and natural wind to dry the product.

2) Traditional drying: brick tunnel kiln, the heat source can choose natural gas, diesel, coal, dry wood, liquefied petroleum gas and other heat sources.

3) New multi-layer drying line: 6-layer metal drying line can save more than 30% energy than transmission drying. The main heat source is natural gas, diesel oil, liquefied petroleum gas, and other clean energy.

- 4. Packaging System

1) Automatic stacking machine

2) baler

3) transport conveyor

Finished Products

The installing issue: Shunfu will send engineers to customers' place. The customer should help installation, the engineer is responsible for installation, testing and training for about 30 days. Below is some picture of installation case for your reference:

3000PCS PER HOUR EGG TRAY MACHINE HAVE BEEN INSTALLED IN MEXICO

5000PCS PER HOUR EGG TRAY MACHINE WITH METAL DRYER OVEN EXPORTED TO UZBEKISTAN

3500PCS PER HOURS EGG TRAY MACHINE EXPORTED TO MIDDLE EAST

We are supplying not only egg tray machine production line, but also other paper processing machine. For more information, pls check it as below:

- Toilet Paper Machine

- Toilet Paper Rewinding Machine

- Napkin Paper Machine

- Kraft Paper Machine

- Kraft Paper Slitting Machine

- Paper Tube Machine

- Paperboard Machine

- Egg Tray Machine