5-10t/h animal feed production line

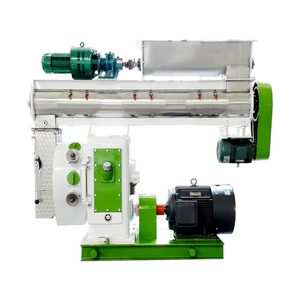

The project is a full-computer automated feed production line that produces 10 tons per hour of animal feed.

MUFENG not only builds the most advanced, reasonable and energy-saving automatic production lines for customers, but also selects complete sets of mechanical equipment with excellent quality and performance, and arranges construction strictly according to the schedule.