- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HAOLU

-

Dimension(L*W*H):

-

Varies

-

Weight:

-

15 KG

-

Marketing Type:

-

New Product 2023

-

Product name:

-

Double roller crusher

-

Keyword:

-

Roller crusher

-

Quality:

-

Advanced Technology

-

Advantage:

-

Energy Saving Consumption

-

The Machines classification:

-

Crushing Line

-

Color:

-

Customizable

-

Usage:

-

Crushing Work

-

Processed Materials:

-

Limestome

-

Applicaton:

-

Mining

-

Installation:

-

Engineer Guide

Quick Details

-

Application:

-

Mining plant

-

Capacity(t/h):

-

Max 50 t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HAOLU

-

Dimension(L*W*H):

-

Varies

-

Weight:

-

15 KG

-

Marketing Type:

-

New Product 2023

-

Product name:

-

Double roller crusher

-

Keyword:

-

Roller crusher

-

Quality:

-

Advanced Technology

-

Advantage:

-

Energy Saving Consumption

-

The Machines classification:

-

Crushing Line

-

Color:

-

Customizable

-

Usage:

-

Crushing Work

-

Processed Materials:

-

Limestome

-

Applicaton:

-

Mining

-

Installation:

-

Engineer Guide

NO.1 Product Description

Roll crusher is also called double roll crusher, double teeth roll crusher etc. The surface of roller crusher are made of high manganese steel, which can stand up to heat treatment. Double roller crusher is suitable for rough and intermediate crushing of brittle materials in such industries as cement, chemical industry, electric power, mine, building materials and metallurgy. The grain size of the input material is large, the particle size of the output product can be controlled, and it is possible to effectively destroy the material whose compressive strength is less than 160 MPa.

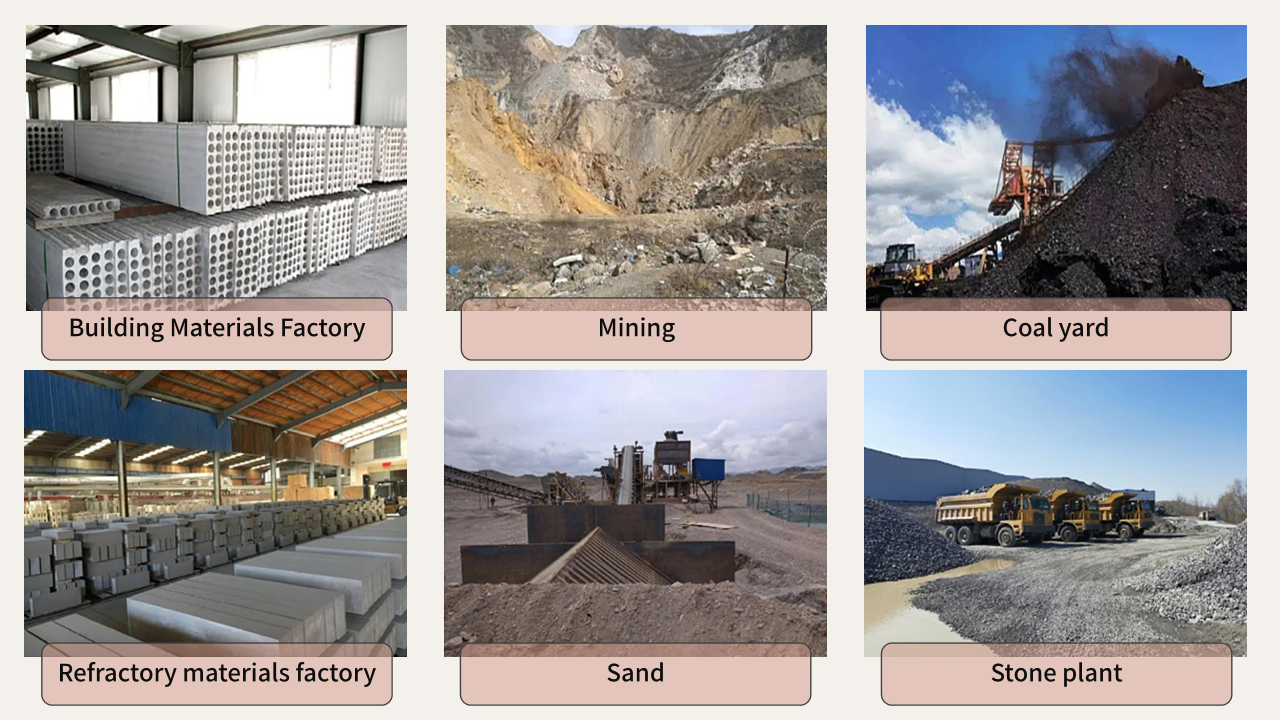

NO.2 Product Application

Roller crusher can be used for crushing various high and medium hardness ores and rocks in pharmaceutical, mineral processing, refractory materials, ceramics, abrasives, building materials, chemicals, cement and other industrial sectors. Suitable for crushing heavy calcium, calcium carbonate, calcium magnesium, quartz stone, mica, potassium albite, limestone, river pebbles, copper ore, bauxite, barite, basalt, steel slag, cement clinker, waste waste, concrete, coal, coke, water slag, slag, clay, fertilizer, chemical raw materials, etc.

NO.3 Working Principle

The materials to be crushed fall from the feeding mouth to the space between the two rolls.After being squeezed and crushed, the final products will naturally fall. When there are too hard materials or materials that cannot be crushed, the rolls of the roller crusher will automatically withdraw under the effect of hydraulic cylinder or spring to increase the gap between the rolls, and the too hard materials or the materials that cannot be crushed will fall down.Thus protecting the machine from being damaged. There is a certain gap between the two rolls that rotate at the opposite direction, and the maximum discharging granularity of the final products can be controlled by changing this gap. Double roller crusher's the materials by relying on the two round rollers rotating at the opposite direction, and four-roll crusher crushes the materials by relying on the two pairs of round rollers rotating at the opposite direction.

NO.4 Main Technical Parameters

|

Model

|

Roller Diameter(mm)

|

Feeding Size(mm)

|

Discharging Size(mm)

|

Capacity(t/h)

|

Power(kw)

|

|||||

|

2PG400×250

|

Φ400

|

<25

|

≤3

|

5-10

|

5.5×2

|

|||||

|

2PG450×500

|

Φ450

|

<30

|

≤3

|

8-20

|

7.5×2

|

|||||

|

2PG610×400

|

Φ610

|

<30

|

≤3

|

13-35

|

15×2

|

|||||

|

2PG610×750

|

Φ610

|

<30

|

≤3

|

16-40

|

22×2

|

|||||

|

2PG750×500

|

Φ750

|

<3030

|

≤3

|

16-40

|

22×2

|

|||||

|

2PG800×600

|

Φ800

|

<30

|

≤3

|

20-40

|

30×2

|

|||||

|

2PG800×800

|

Φ800

|

<30

|

≤5

|

20-50

|

37×2

|

|||||

|

2PGY1000×800

|

Φ1000

|

<30

|

≤5

|

40-70

|

55×2

|

|||||

|

2PGY1200×1000

|

Φ1200

|

<30

|

≤5

|

60-100

|

90×2

|

|||||

|

2PGY1200×1200

|

Φ1200

|

<30

|

≤5

|

80-130

|

110×2

|

|||||

|

2PGY1500×1000

|

Φ1500

|

<30

|

≤5

|

100-150

|

132×2

|

|||||

|

2PGY1500×1200

|

Φ1500

|

<30

|

≤5

|

150-200

|

160×2

|

|||||

|

2PGY1800×1000

|

Φ1800

|

<30

|

≤5

|

220-300

|

200×2

|

|||||

|

2PGY2000×1200

|

Φ2000

|

<30

|

≤5

|

300-400

|

250×2

|

|||||

|

The above data are for reference only and are subject to specific conditions.

|

|

|

|

|

|

|||||

NO.5 Main Features

1. Compact structure, reliable performance

2. Low noise and high efficiency

3. Easy to install and only need simple foundation

4. It can adjust the pressure and size easily, and can be made to meet the customer's request

5. Self-protection, the parts can not be damaged when hard materials such as the metals goes into the crushing cavity

6. Low attrition rate and easy to maintain

Hot Searches