- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Changrong

-

Voltage:

-

380V

-

Weight:

-

16000 kg

-

Product name:

-

Automatic flatbed die cutting machine machine

-

After-sales Service Provided:

-

Overseas Service Provided

-

After Warranty Service:

-

Viedo Technical Support

-

Application:

-

Printing Company

-

Function:

-

Die Cutting

-

Keyword:

-

Die cutting

-

certification:

-

ISO/CE

-

Advantage:

-

High Efficency

-

Power Supply:

-

380V/3PH/50HZ

Quick Details

-

Type:

-

Paper Embossing Machine

-

Production Capacity:

-

100 m/min

-

Max. workable width:

-

1060mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Changrong

-

Voltage:

-

380V

-

Weight:

-

16000 kg

-

Product name:

-

Automatic flatbed die cutting machine machine

-

After-sales Service Provided:

-

Overseas Service Provided

-

After Warranty Service:

-

Viedo Technical Support

-

Application:

-

Printing Company

-

Function:

-

Die Cutting

-

Keyword:

-

Die cutting

-

certification:

-

ISO/CE

-

Advantage:

-

High Efficency

-

Power Supply:

-

380V/3PH/50HZ

Products Description

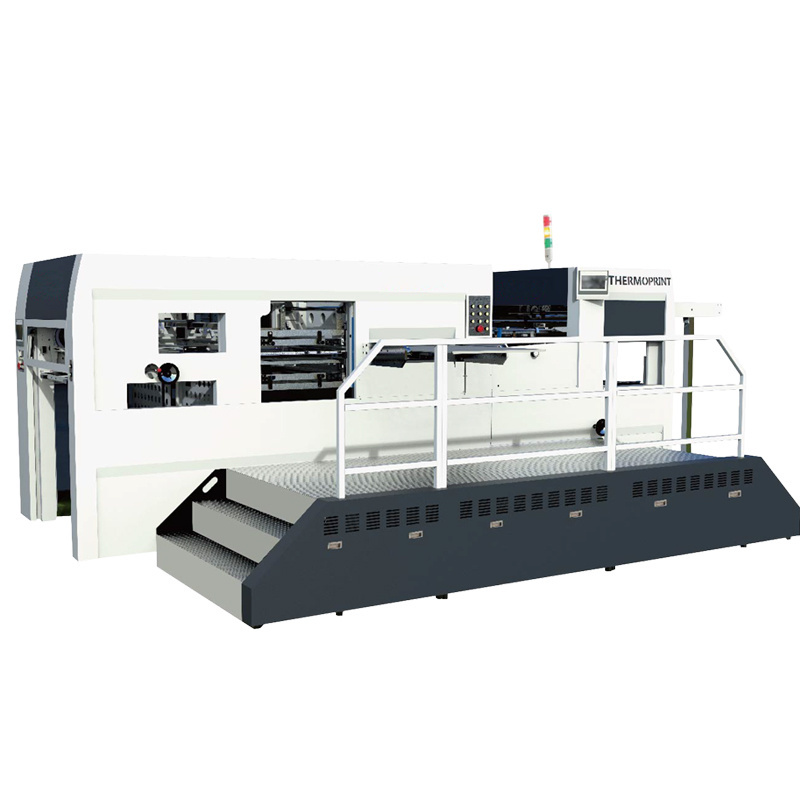

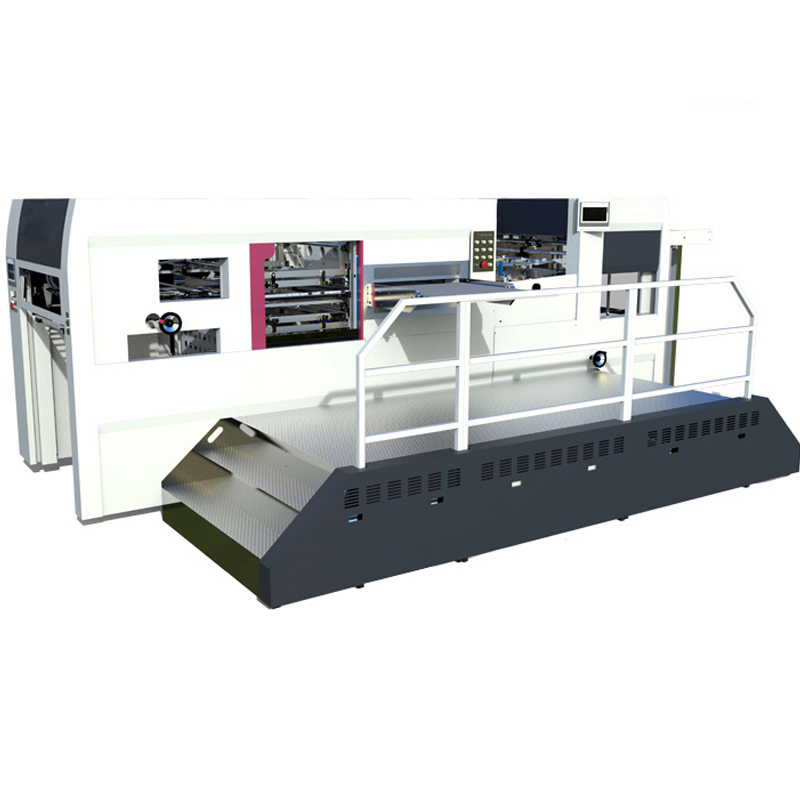

CR1060MY automatic flatbed die cutting machine

Feeder:

The feeder adopts the European technology with four suckers and four blowers.The suckers are adjustable to ensure the steady conveying of different type and shape of paper without stopping the machine.The easy to be adjusted

functions can do thin an think paper for an accurate convey.

functions can do thin an think paper for an accurate convey.

Title goes here.

Auxiliary Blowing Device for Thin Paper Feeding

Title goes here.

Sheet Separating Blowing Device

at Transport Bracket.

at Transport Bracket.

Side Lay:

The side lay,after special desige,contains push and pull.You can choose the proper one according to different products wirh no need of changing parts.There is little movement of paper while the side lay is working and no worn for paper that contribute to transfering paper in high

speed.

speed.

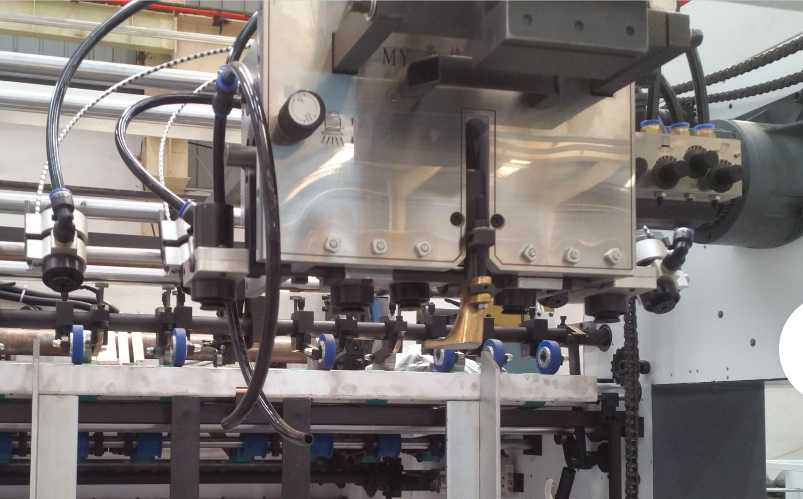

Gripper bar and Chain:

Special super-hard aluminum alloy type material is used for the Gripper bar,the surface is

anodized,accurate Die cutting can be realized in the adjustment Operation,perfect precision control;gripper bar Main chain adopt special chains,The strength Is relatively

increased by about 45%,improve Stability of precision,prolong service life.

Main Transmission:

Worm shaft material is made of German alloy copper,Precision machine processing,high precision, especially wear-resistant.Bent axle,worm is use forging grinding and high quenching process,long service life.The swing rod size is increased,the pendulum shaft is thickened,so the die cutting is high,Wear-resisting durable.

Pneumatic clutch:

Imported components to lower noise and

pneumatic impact for stable and safe

running.Comply with European export

standards. The clutch is more stable

using the Italian yuyi.

pneumatic impact for stable and safe

running.Comply with European export

standards. The clutch is more stable

using the Italian yuyi.

Main Chain drive:

Chain of main machine is made by Renold,Germany,Taiwan

intermittent mechanism drive,improve precision of die

cutting,ensure equipment safety,avoid machine damage,improve service life.

intermittent mechanism drive,improve precision of die

cutting,ensure equipment safety,avoid machine damage,improve service life.

Main motor

Anti-explosion OF Brazilian WEG

Frequency converter

Transducer of SIEMENS

Die-cutting part:

The safety design of the die-cutting bottom plate and the knife template, and the design of the easy moving and rotating device make the plate-loading and plate-setting faster and more convenient. Pneumatic stable

recovery. Non-stop feeding and delivery

device.

Title goes here.

Fixed in a central positioning

line; Knife plate around the screw fixed

clamp; Choose claw screw positioning

and fixing

Flexible Foil Unwinding Rack:

So sensitive,effectively ensuring safe

running of the machine and

minimizing the personal injury to

operator

Locking plate with fast automatic locking device:

The lower locking plate has a fast locking device; One-button lock button, when the light is off, it is locked, and when the light is on, it is loose, which realizes toolless fast lock board and reduces debugging time.

Title goes here.

The pressure adjustment is on the screen

to achieve electric increase and reduce pressure;

Man-machine interface can be operated

on the receiving side and the operating side;Both human-machine interfaces can realize all operation of the machine.

Delivery section:

The paper damping and deceleration adopts a mechanical

delivery presser brush mechanism, which enables the paper flat locking device to fix the upper frame more

firmly, more accurately and saves time. Safer and more reliable

Man-machine interface:

This machine adopts Imported high resolution man-machine interface for man-machine communication,it can monitor and display the running status of the machine in real time, provide detailed operation and troubleshooting

Methods for machine adjustment and

troubleshooting.

Title goes here.

The machine is controlled by SIEMENS

PLC,frequency conversion.All kinds of electrical components,the switch used

in Japan,France,Taiwan and other

famous brand products.Accurate operation control and stable performance.

Product Paramenters

|

Max sheet size

|

1060mm*780mm

|

|

Min sheet size

|

400mm*350mm/400mm*260mm(Patent option)

|

|

Max die cuting size

|

1050mm*770mm

|

|

Gripper margin

|

≥6mm

|

|

innerchase size

|

1120mm*786mm

|

|

Stock range

|

80~2000g/㎡ paper 0.1~2mm papers≤5mm corrugated

|

|

Die cutting accuracy

|

≥士0.075mm

|

|

Max die cutting force

|

450tons

|

|

Max die cutting speed

|

7500p/h

|

|

Maxfeeder pile height

|

1600mm(wooden pallet included)

|

|

Max delivery pile height

|

1500mm(wooden pallet included)

|

|

Air requirement

|

0.6~0.7Mpa>0.6m3/min

|

|

Net weight approx

|

About 16tons

|

|

Main motor wattage

|

11KW

|

|

Full load wattage

|

17kw

|

|

Overall dimension

|

6500mm(L:Pre ~ load paper device included)x4000mm(W:Platform included)x2300mm(H)*

|

Hot Searches