Product name:Automatic Vaccine Continuous Syringe machine

Features of chick automatic vaccine machine

Product acessories

|

1 |

Injection power |

Motor |

|

2 |

Power supply |

220 volts AC |

|

3 |

Injection dose |

0.15ml~0.3ml adjustable dose (can be customized according to demand) |

|

4 |

Injection dose accuracy |

±0.01ml |

|

5 |

Contact with pharmaceutical parts materials |

Rubber, Stainless steel |

|

6 |

Suitable for injections |

Chickens, ducklings, goslings within 7 days of age |

|

7 |

Applicable vaccine type |

Water-based vaccine, oil-based vaccine |

|

8 |

The maximum injection speed |

2500--5500 feathers/hour. |

|

9 |

Product net weight |

15kg |

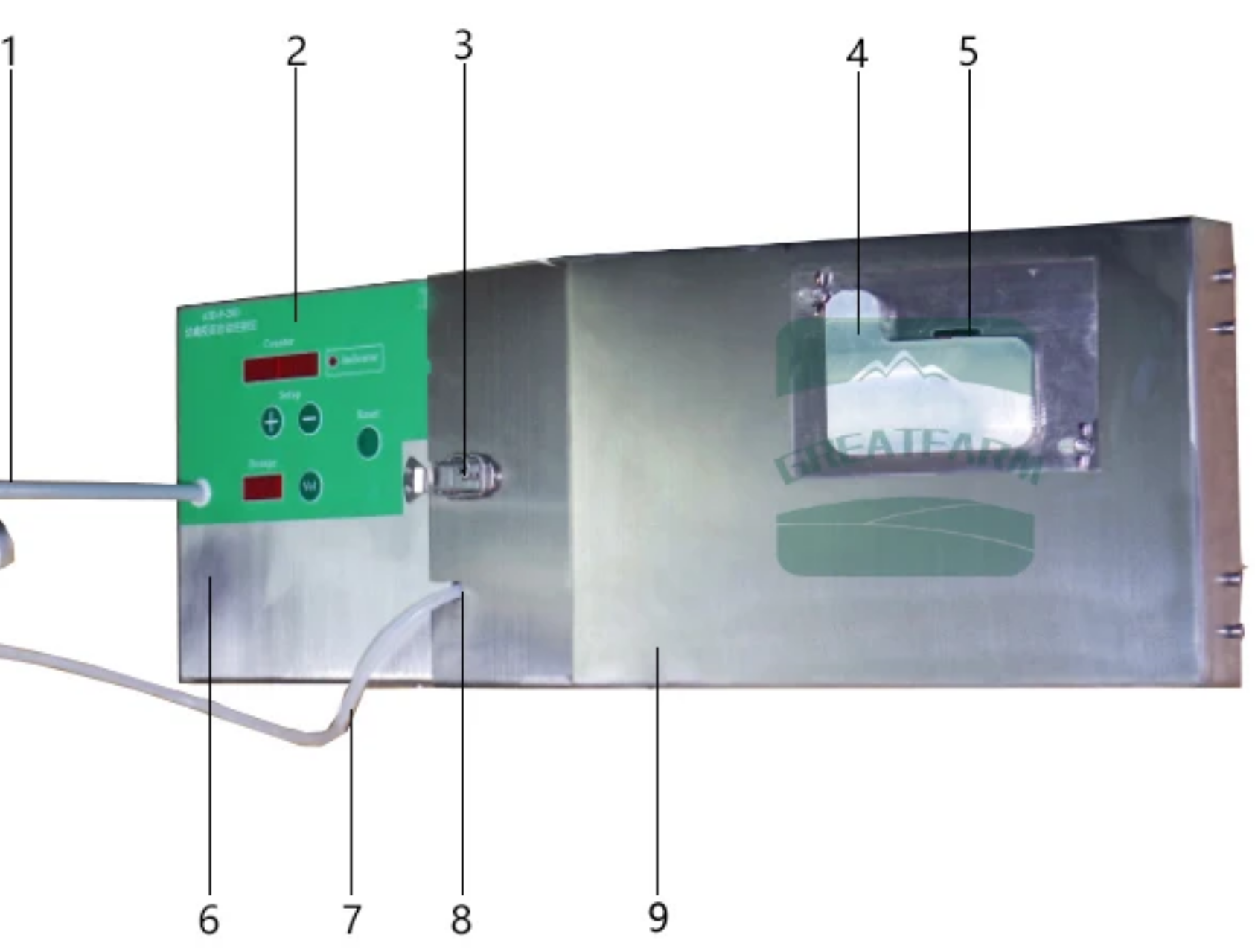

NO.1 Machine composition introduction

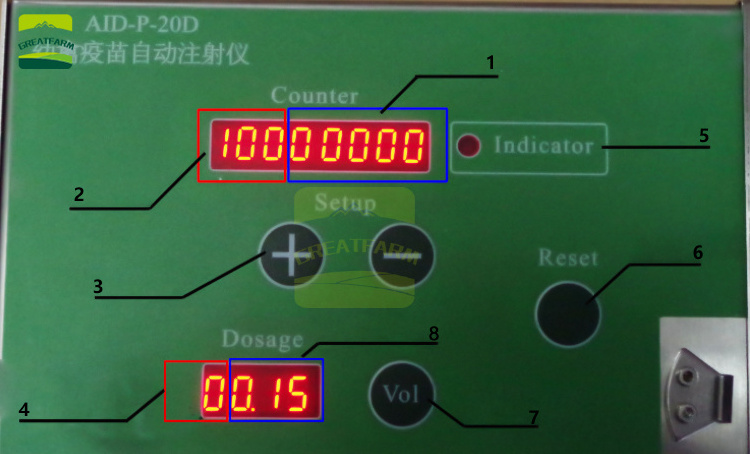

NO.2 Control panel introduction

-1. Count display area

Chick automatic vaccine continuous injection machine introduction

1.Introduction to the installation steps

Step 1: Install the needle (please use the needle we provide, or use the same size as the needle)

1 Remove the mast;

2 Insert the threaded end of the rod into the hole above the main unit-1;

3 Press down and rotate the lever to secure it to the main unit-2.

Vaccine bottle holder is installed Finished(Step 2 is shown in the picture below).

1 Connect one end of the hose to the long needle;

2 Connect the hose through the inlet hole on the housing to the inlet fitting of the ampoule;

3 Insert the long needle into the prepared vaccine bottle;

4 Hang the vial on the pole.

Hose and vial access completed (Step 3 is shown in the picture below).

2.Operational guidance

Step 1:Preparation before injection

1 Connect the dedicated power cable to 220V AC and plug it into the host power socket.

2 Turn on the power switch;

3 Press the trigger switch several times with the foreign object until the needle has a stable jet, indicating that the air in the pipe is removed;

4 Press the clear button located on the top of the main unit to reset the LED display to zero;

5 Press the dose setting button to set the desired dose.

Complete the preparation process.

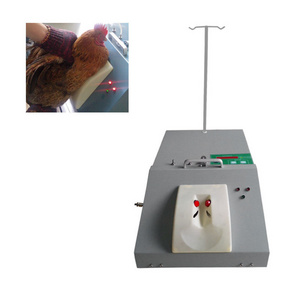

Step 2: Injection (recommended for the novice to perform the injection operation according to the following specifications)

The correct standing position of the operator, as well as the orientation of the machine and the chicken frame.

2 Fit the chicken head to the groove of the cover;

3 Maintaining the above position will push the neck of the chicken to the left to make it touch the trigger switch to complete the injection;

1 Open the flip cover;

2 Attach the infusion hose to a disposable syringe that has been filled with sterile alcohol (or boiled water, approximately 20 ML);

3 Push the syringe, at this time, a jet is sprayed from the needle to complete the cleaning and disinfection of the inside of the pipeline;

4 Close the flip cover.

Step 2: Internal pipelines and components are disinfected regularly

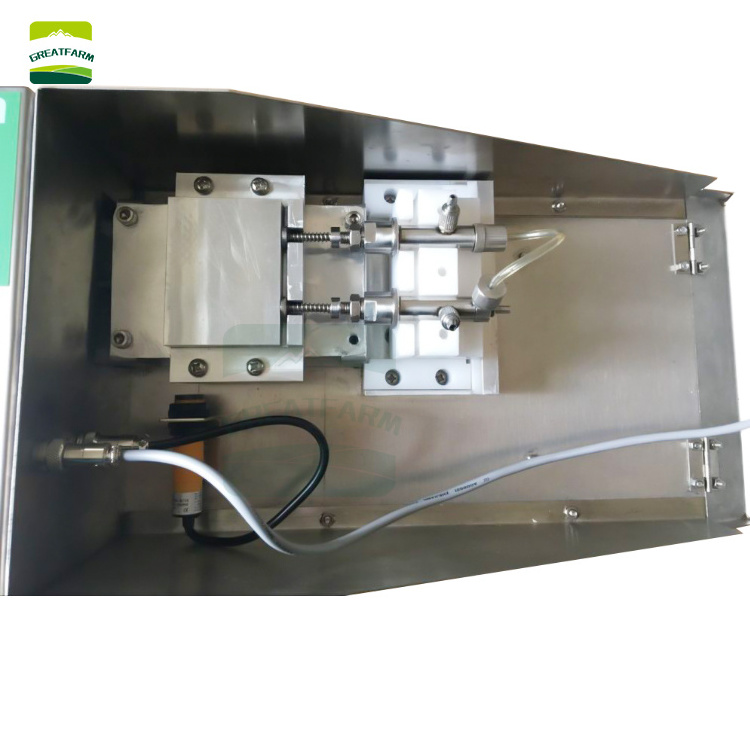

1 Loosen the lock and open the flip cover;

2 Hold the front and rear ends of the syringe;

3 Remove the syringe-1 upwards and remove the inlet hose-2;

4 Disassemble the syringe and disinfect the syringe;

-1. Sealing washer;

-2. Long spring;

-3. Valve-core;

-4. Short spring;

-5. Sealing washer;

-6. O-ring;

-7. Sealing washer.

* Disassemble and disinfect the syringe as shown in the figure. It is recommended once a month.

2 When the aqueous vaccine was injected, the adjustment value was shown as "H"; when the oily vaccine was injected, the adjustment value was shown as "P".

5. Adjustment of the injection dose

1 In the “Dosage” area of the LED display, the last three digits are the values of the required dose.

2 This value can be adjusted with the “Vol” button. The adjustment positions are: 0.15, 0.2, 0.25, 0.3 four dose positions.

6. Adjustment of the number of alarms

1 In the “Counter” area of the LED display, the first three digits are the alarm number value, and the last five digits are the number of injections.

2 The number of alarms can be adjusted by the “+ /-” button, and the range is (0-200).

7. Product maintenance and precautions

1 When the machine emits a "drip..." long beep, note that the injection count has reached the set number of times;

2 When you need to re-count, please press the green clear button to reset the number of displayed injections to zero;

3 When not in use, please turn off the power switch;

4 After use, please open the flip cover and dry the internal water mark.

5 Do not touch the micro switch at the front end when not injecting, so as not to cause injury to personnel.

1. We accept Alipay, West Union, TT. All major credit cards are accepted through secure payment processor ESCROW.

2. Payment must be made within 3 days of order.

3. If you can't checkout immediately after auction close, please wait for a few minutes and retry Payments must be completed within 3 days.

Contact us:

Name:Penn Chang

WhatsApp:+ 86 15090457829

Phone:0086 18203631302

WeChat:18203631302