- Product Details

- {{item.text}}

Quick Details

-

MOQ:

-

1 Piece

-

SAMPLE:

-

Avaiable

-

Payment term:

-

50% Deposit 50% Balance

-

Certification:

-

ISO9001

-

Material:

-

Aluminum,stainless steel,carbon steel,titanum alloy etc

-

Drawing format:

-

2D/(PDF/CAD)3D(IGES/STEP)

-

Inspection:

-

100% Test

-

Delivery time:

-

7-25 Days

-

Application:

-

Industry Machinery

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Yuanda

-

Model Number:

-

dis casting

-

MOQ:

-

1 Piece

-

SAMPLE:

-

Avaiable

-

Payment term:

-

50% Deposit 50% Balance

-

Certification:

-

ISO9001

-

Material:

-

Aluminum,stainless steel,carbon steel,titanum alloy etc

-

Drawing format:

-

2D/(PDF/CAD)3D(IGES/STEP)

-

Inspection:

-

100% Test

-

Delivery time:

-

7-25 Days

-

Application:

-

Industry Machinery

Specification

|

Surface treatment

|

Blasting, polishing

|

|

Service

|

OEM

|

|

Process

|

Die Casting+ Machining

|

|

Package Details

|

1.Place the parts on the wooden pallet first, and then fix them with strapping straps. At the same time, in order to prevent the

strapping from affecting the surface of the parts, it is necessary to place partitions such as foam between the parts and under the strapping straps.

2.After separating the parts with plastic foam, arrange them neatly, and then pack them in wooden boxes.

|

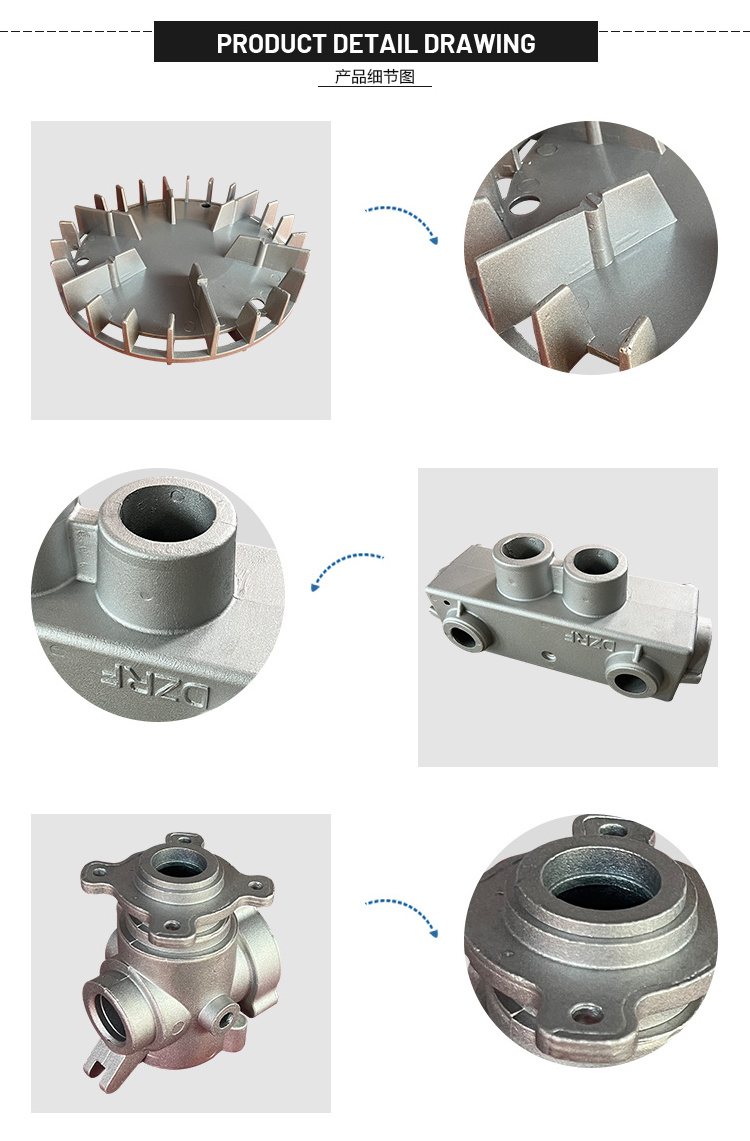

Details Images

Die casting workshop

Packing & Delivery

After separating the parts with plastic foam, arrange them neatly, and then pack them in wooden boxes.

Place the parts on the wooden pallet first, and then fix them with strapping straps. At

the same time, in order to prevent the strapping from affecting the surface of the parts, it is necessary to place partitions such

as foam between the parts and under the strapping straps.

the same time, in order to prevent the strapping from affecting the surface of the parts, it is necessary to place partitions such

as foam between the parts and under the strapping straps.

Hot Searches